Augmented Vision Systems for Large-Format UV Printing

Introduction

In the fast-evolving world of printing technology, large-format UV printing has become a cornerstone for industries ranging from advertising to interior design. To enhance efficiency and precision, augmented vision systems are making significant inroads into this domain. These systems integrate advanced imaging technologies with real-time data processing, enabling the production of high-quality prints with remarkable accuracy.

The Need for Augmented Vision in Large-Format UV Printing

As the demand for large-format UV printing increases, so does the complexity of the tasks involved. The need for precision and speed has never been more critical. Augmented vision systems help in achieving these goals by providing an additional layer of information that aids in decision-making and operational efficiency.

Challenges in Large-Format UV Printing

Large-format UV printing comes with its own set of challenges:

·

Alignment Issues: Misalignment can lead to wasted materials and unsatisfactory prints.

·

·

Color Accuracy: Maintaining color fidelity is crucial, especially for branding and marketing materials.

·

·

Production Speed: The need for faster turnaround times can lead to quality compromises.

·

How Augmented Vision Systems Address These Challenges

By incorporating augmented vision systems, businesses can tackle these challenges head-on:

·

Real-time Feedback: These systems provide immediate visual feedback, reducing alignment errors.

·

·

Color Calibration: Advanced sensors help in accurate color reproduction throughout the printing process.

·

·

Increased Efficiency: Automation of quality checks accelerates workflows and ensures high-quality output.

·

Benefits of Augmented Vision Systems

The implementation of augmented vision systems in large-format UV printing offers numerous benefits, making it a worthwhile investment for businesses aiming to improve productivity and quality.

Enhanced Accuracy

Augmented vision systems use sophisticated imaging technology to deliver enhanced accuracy in print alignment and registration. This level of precision reduces errors and minimizes waste, ultimately saving time and resources.

Improved Quality Control

Quality control becomes more efficient with real-time monitoring capabilities. These systems can detect imperfections or deviations from the required standards, allowing operators to address issues before they develop into larger problems.

Streamlined Workflow

By automating repetitive tasks such as alignment checks and color adjustments, augmented vision systems streamline workflows. This results in faster production times and the ability for operators to focus on more critical tasks.

Cost Efficiency

With reduced waste and improved production speeds, companies can lower their operational costs. In an industry where margins can be tight, these savings can significantly impact the bottom line.

Key Features of Augmented Vision Systems

Understanding the features of augmented vision systems can help businesses evaluate their suitability for large-format UV printing needs.

High-Resolution Imaging

High-resolution cameras provide detailed visuals that enhance decision-making. The better the image quality, the more accurate the adjustments can be.

Real-time Data Processing

Real-time data processing capabilities allow for immediate corrections and adjustments, thereby reducing the likelihood of errors during printing.

User-friendly Interfaces

Most augmented vision systems come with intuitive user interfaces that make them easy to operate. This ensures that operators can quickly understand and leverage the technology without extensive training.

Integration Capabilities

These systems are often designed to integrate seamlessly with existing printing workflows, making the implementation process smoother.

Conclusion

As the printing industry continues to evolve, augmented vision systems represent a significant advancement in achieving precision and quality in large-format UV printing. By embracing this technology, businesses can enhance accuracy, improve workflow efficiency, and ultimately deliver better products to their clients. With benefits that include cost efficiency, quality control, and streamlined operations, the integration of augmented vision systems is not just a trend; it's a necessity for any company aiming to stay competitive.

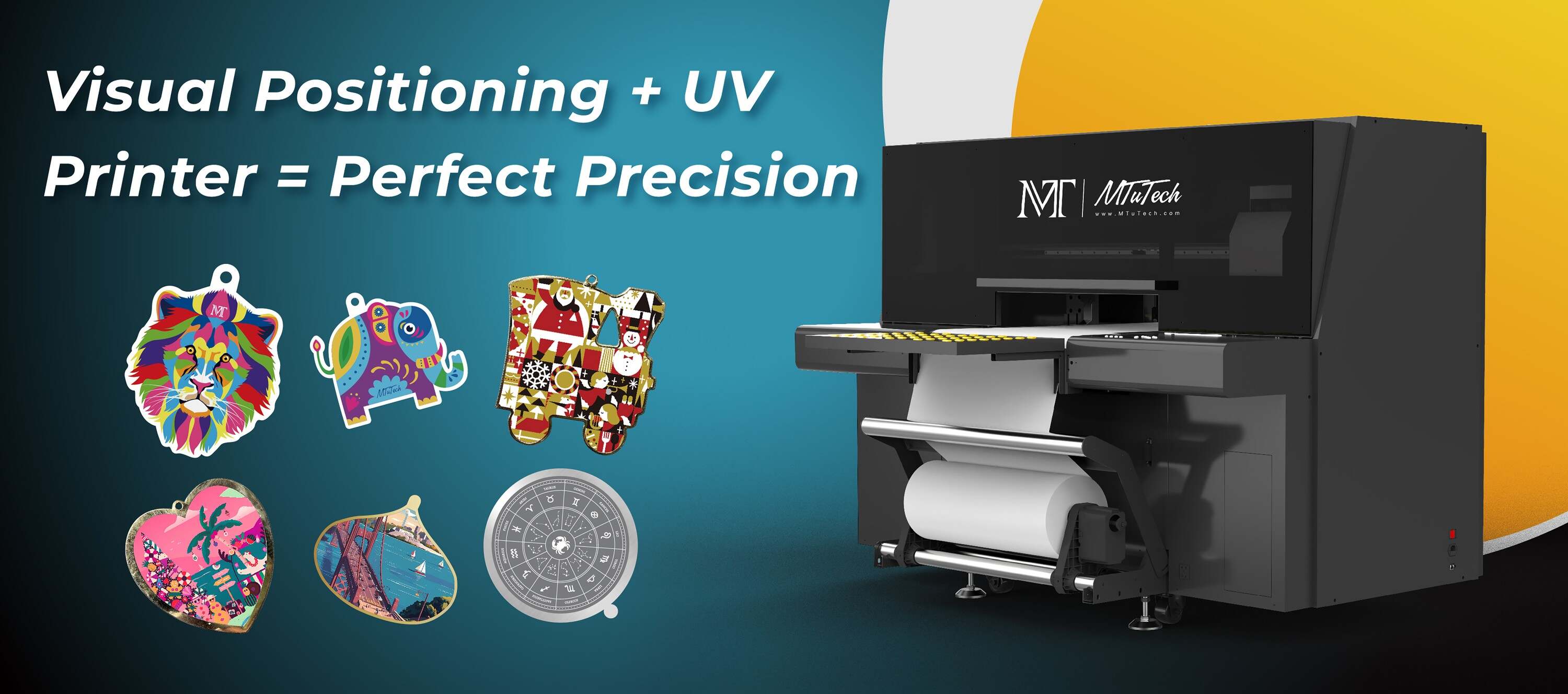

If you're considering upgrading your printing capabilities, explore our high-quality Visual Positioning UV printers here. These systems not only incorporate augmented vision technology but also promise to enhance your printing quality and efficiency, ensuring you stay ahead in the industry.

FAQ

What are augmented vision systems?

Augmented vision systems are advanced imaging technologies that provide real-time visual data and feedback, enhancing operational efficiency and accuracy in printing processes.

How do augmented vision systems improve large-format UV printing?

These systems help improve alignment and color accuracy, streamline workflows by automating quality checks, and provide real-time feedback, which ultimately enhances the overall printing quality.

Are augmented vision systems easy to integrate with existing workflows?

Yes, most augmented vision systems are designed for easy integration with existing printing setups, ensuring a smooth transition and minimal disruption to operations.

What cost benefits can I expect from using augmented vision systems?

By reducing material waste, improving production speeds, and enhancing quality control, augmented vision systems can significantly lower operational costs, making them a worthwhile investment for printing businesses.

Do I need specialized training to operate augmented vision systems?

No, most augmented vision systems come equipped with user-friendly interfaces that simplify operation, minimizing the need for extensive training for operators.