Monocular vs Stereo Vision in UV Printing

The UV printing industry has evolved rapidly over the last decade, driven by increasing demand for precision, speed, and customization. As print applications become more complex—ranging from flat substrates to uneven, three-dimensional objects—the role of vision systems in UV printers has become more critical than ever. Vision technology acts as the “eyes” of the printer, guiding accurate alignment, positioning, and inspection throughout the printing process.

Among the available vision technologies, monocular vision and stereo vision are the two most commonly adopted systems. Each comes with its own strengths, limitations, and ideal use cases. Choosing the right vision system is not merely a technical decision; it directly impacts print accuracy, production efficiency, operational costs, and future scalability.

This article provides an in-depth, practical comparison of monocular and stereo vision systems in UV printing. By the end, you will have a clear understanding of how each system works, where it performs best, and how to choose the most suitable option for your printing requirements—without unnecessary complexity or marketing hype.

The Role of Vision Systems in UV Printing

Vision systems in UV printers serve multiple essential functions. They enable precise positioning of print heads, detect substrate boundaries, align graphics accurately, and assist in quality inspection. Without an effective vision system, even the most advanced UV printer can struggle with misalignment, print inconsistency, and material wastage.

Modern UV printing relies heavily on automation. Vision systems provide real-time feedback, allowing printers to adapt to slight variations in substrate placement, size, and surface texture. This capability is particularly important in short-run and customized printing environments where manual adjustments are impractical.

As printing moves toward higher levels of automation and smart manufacturing, vision technology is no longer optional—it is a foundational component of reliable UV printing workflows.

Understanding Monocular Vision Systems

What Is Monocular Vision?

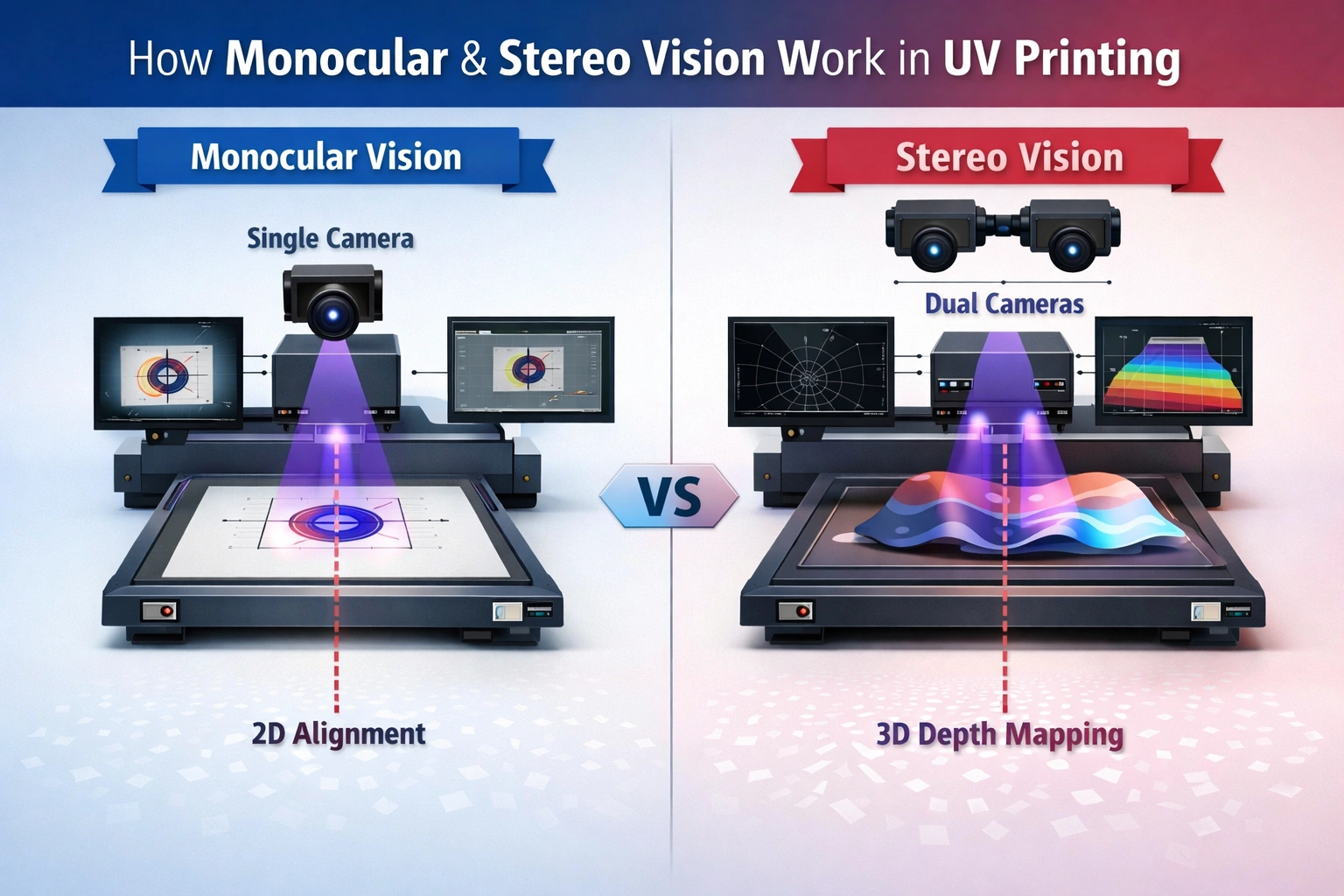

Monocular vision systems use a single camera to capture images of the printing surface. The system analyzes two-dimensional visual data to determine position, orientation, and alignment. While it does not inherently provide depth information, monocular vision compensates through algorithms, reference markers, and known object dimensions.

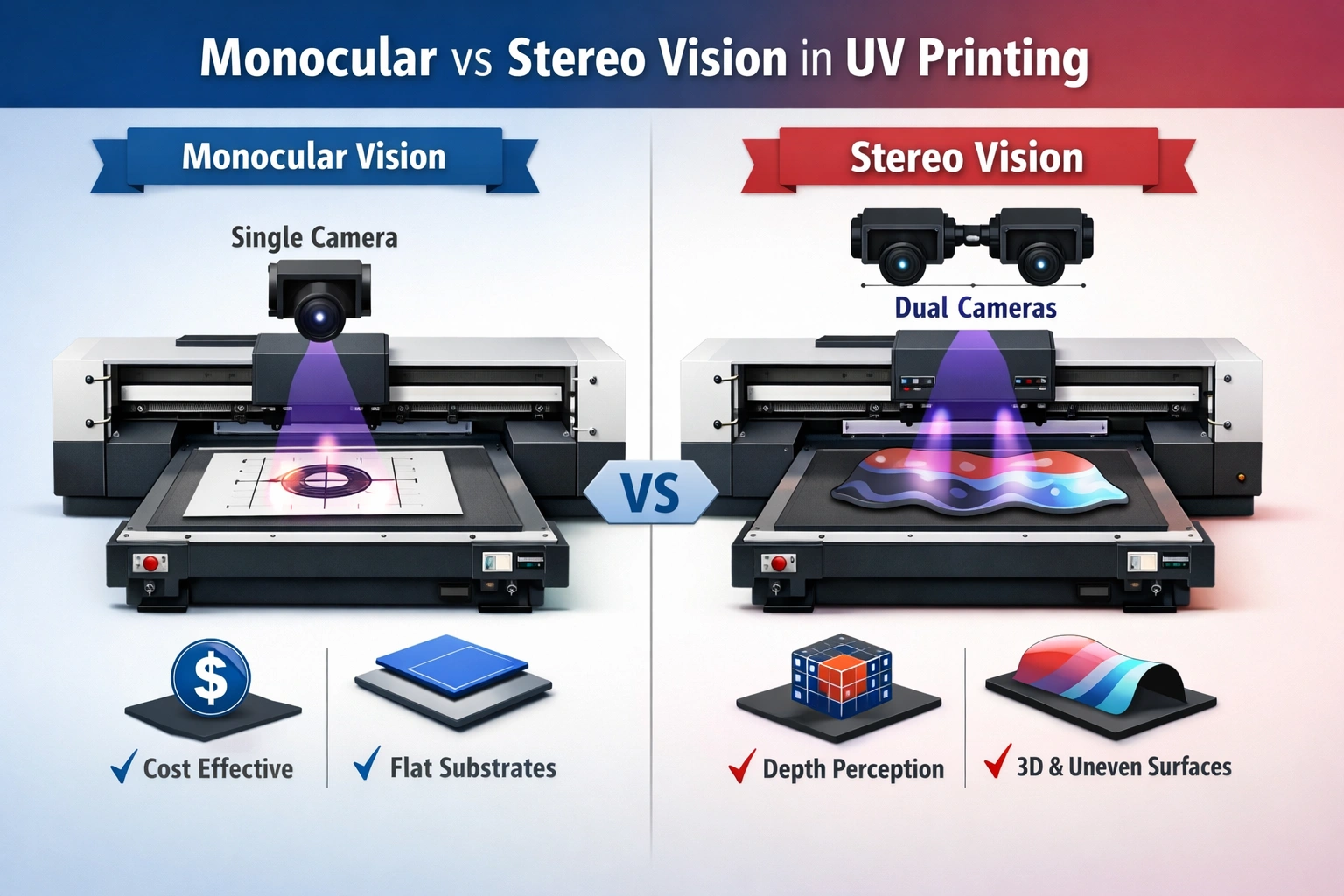

This type of vision system is widely used due to its simplicity and cost efficiency. For many flat and uniform substrates, monocular vision delivers excellent performance with minimal complexity.

How Monocular Vision Works in UV Printing

In a UV printing setup, the monocular camera captures images of the substrate before and during printing. The software identifies edges, markers, or contrast differences to calculate alignment corrections. Once calibrated, the printer uses this data to adjust print head positioning in real time.

Monocular systems rely heavily on consistent lighting, stable camera placement, and predictable substrate characteristics. When these conditions are met, the system performs reliably and efficiently.

Advantages of Monocular Vision

Cost Efficiency

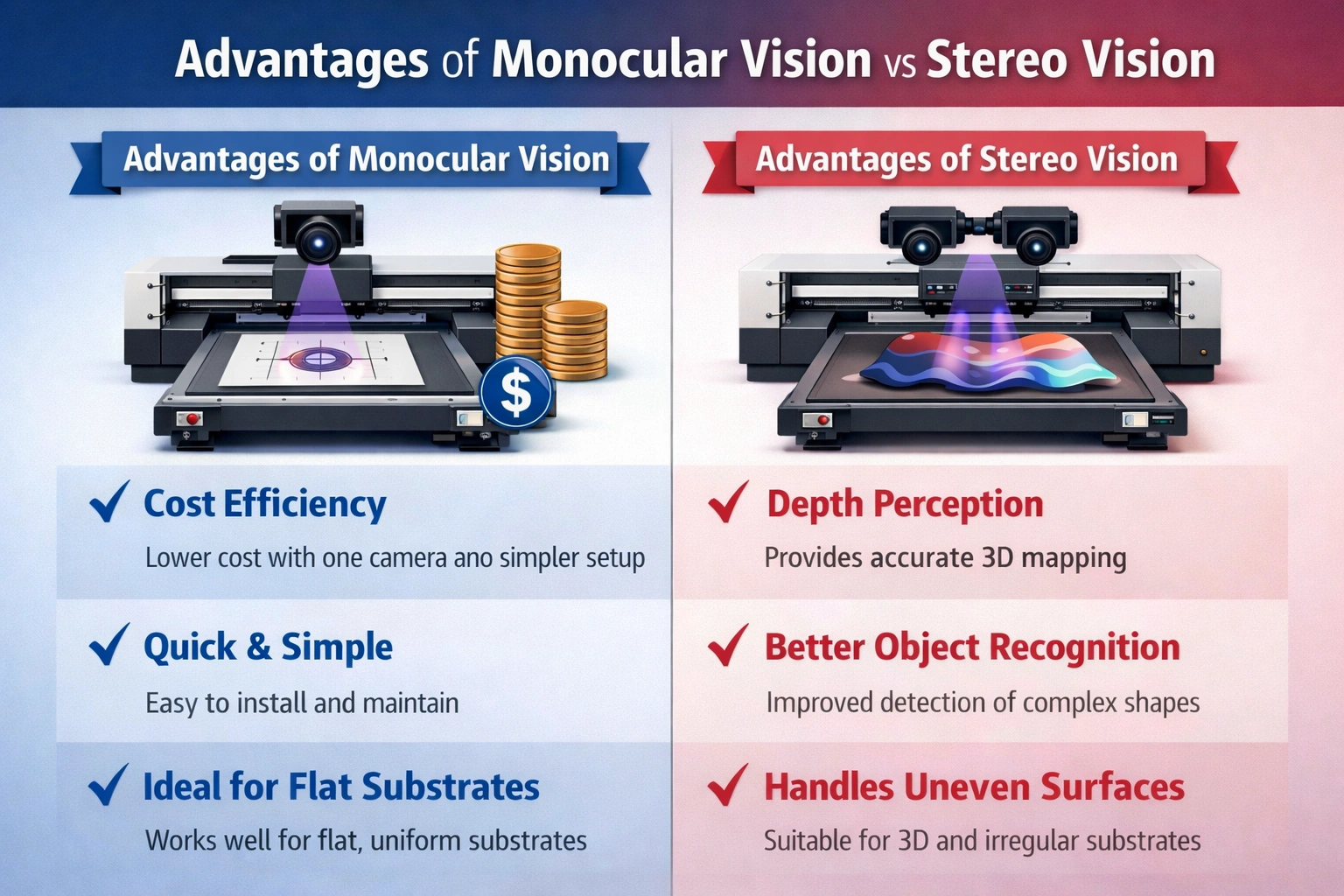

One of the strongest advantages of monocular vision is affordability. With only one camera and simpler processing requirements, the overall system cost remains low. This makes it an attractive option for small to medium printing businesses.

Simpler Installation and Maintenance

Monocular systems are easier to install and calibrate. Fewer components mean reduced setup time and lower maintenance demands. This simplicity also minimizes downtime caused by technical issues.

Faster Processing

Because monocular vision processes less data than stereo systems, it often delivers faster image analysis. This speed can be beneficial in high-throughput environments where depth information is not required.

Ideal for Flat Substrates

For applications involving flat materials such as acrylic sheets, PVC boards, paper, and metal plates, monocular vision performs exceptionally well.

Limitations of Monocular Vision

Despite its benefits, monocular vision has inherent limitations. The most notable is the lack of true depth perception. While software can estimate depth under controlled conditions, it cannot match the accuracy of stereo vision in complex three-dimensional scenarios.

Monocular systems may struggle with irregular surfaces, varying substrate heights, or objects with significant curvature. In such cases, alignment errors may increase, requiring manual intervention.

Understanding Stereo Vision Systems

What Is Stereo Vision?

Stereo vision systems use two cameras positioned at a fixed distance from each other, similar to human eyes. By capturing images from slightly different perspectives, the system calculates depth through triangulation. This enables accurate three-dimensional mapping of objects and surfaces.

Stereo vision provides richer spatial data, making it suitable for advanced UV printing applications where precision and adaptability are critical.

How Stereo Vision Works in UV Printing

In a UV printer equipped with stereo vision, both cameras capture synchronized images of the substrate. The software compares these images to calculate depth, surface contours, and object orientation. This information allows the printer to adjust print head height, alignment, and ink deposition dynamically.

Stereo vision excels in environments where substrates vary in shape, thickness, or surface geometry.

Advantages of Stereo Vision

Accurate Depth Perception

The most significant advantage of stereo vision is true depth measurement. This capability enables precise printing on uneven, curved, or multi-layered surfaces.

Enhanced Object Recognition

Stereo systems can identify complex shapes and surface variations more accurately. This leads to improved alignment and consistent print quality across diverse materials.

Greater Flexibility

Stereo vision supports a wider range of applications, including cylindrical objects, embossed surfaces, and products with height variations.

Future-Ready Technology

As UV printing continues to evolve toward automation and Industry 4.0 integration, stereo vision offers a more scalable foundation for advanced workflows.

Limitations of Stereo Vision

Stereo vision systems are more expensive due to additional hardware and complex software requirements. Installation and calibration also require higher technical expertise.

Processing stereo image data takes more computational power, which can slightly reduce processing speed compared to monocular systems, particularly in entry-level configurations.

Monocular vs Stereo Vision: A Detailed Comparison

Accuracy and Precision

Monocular vision delivers high accuracy in two-dimensional alignment tasks. However, when depth variation becomes a factor, stereo vision provides superior precision.

Cost Considerations

Monocular systems are budget-friendly and suitable for businesses with cost constraints. Stereo vision represents a higher initial investment but often delivers long-term value through reduced errors and expanded capabilities.

Application Range

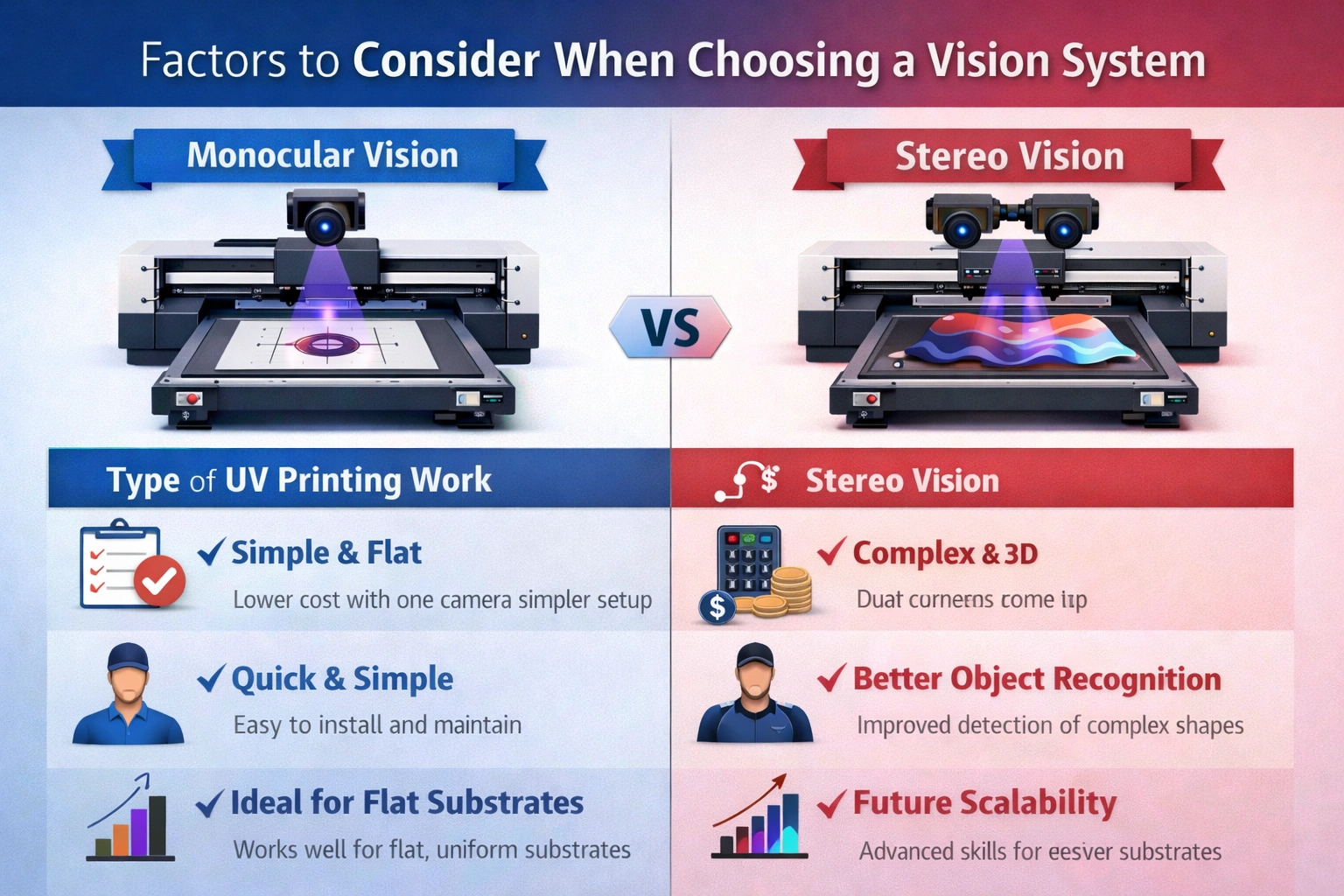

Monocular vision is ideal for flat, uniform substrates and repetitive tasks. Stereo vision supports complex, varied, and high-precision applications.

Ease of Use

Monocular systems are easier to learn and operate. Stereo vision requires more training but offers greater control and adaptability.

Scalability

Stereo vision is better suited for future expansion and integration with advanced automation technologies.

Choosing the Right Vision System for Your UV Printing Needs

Evaluate Your Substrates

If your printing work primarily involves flat materials, monocular vision may be sufficient. For uneven, curved, or multi-dimensional objects, stereo vision is the better choice.

Consider Production Volume

High-volume, repetitive printing environments often benefit from the speed and simplicity of monocular systems. Custom and short-run jobs with varying substrates favor stereo vision.

Assess Budget and ROI

While monocular vision reduces upfront costs, stereo vision can offer higher returns over time by minimizing errors, waste, and manual adjustments.

Analyze Technical Resources

Ensure your team has the expertise to operate and maintain the chosen system. Stereo vision may require additional training and support.

Integration Best Practices for Vision Systems

Proper Calibration

Accurate calibration is essential for both monocular and stereo systems. Regular recalibration ensures consistent performance.

Controlled Lighting

Stable and uniform lighting improves image clarity and reduces recognition errors, especially in monocular setups.

Software Optimization

Choose software that complements your vision system and supports real-time adjustments.

Routine Maintenance

Clean lenses, check camera alignment, and update software regularly to maintain optimal performance.

Future Trends in Vision-Enabled UV Printing

Vision systems are becoming smarter with the integration of artificial intelligence and machine learning. These advancements allow printers to self-correct, predict errors, and adapt to new substrates automatically.

Stereo vision is expected to play a significant role in future UV printing innovations, particularly in automated inspection and smart manufacturing environments. However, monocular vision will continue to remain relevant for cost-sensitive and straightforward applications.

Conclusion

Choosing between monocular and stereo vision for UV printing is not about identifying a universally superior option—it is about selecting the right tool for your specific needs. Monocular vision offers simplicity, affordability, and efficiency for flat and predictable printing tasks. Stereo vision provides advanced depth perception, flexibility, and precision for complex and evolving applications.

By understanding the strengths and limitations of each system, you can make an informed decision that enhances print quality, improves productivity, and supports long-term growth. A well-chosen vision system is an investment in consistency, accuracy, and the future of your UV printing operation.

For those interested in enhancing their UV printing capabilities, explore our high-quality Visual Positioning UV printers here and see what innovative solutions we offer to maximize your potential in this evolving industry.

Frequently Asked Questions

What is the main difference between monocular and stereo vision?

Monocular vision uses one camera and provides two-dimensional data, while stereo vision uses two cameras to generate three-dimensional depth information.

Is monocular vision suitable for professional UV printing?

Yes, for flat substrates and standard alignment tasks, monocular vision performs very well.

Does stereo vision improve print quality?

Stereo vision improves accuracy on uneven or complex surfaces, which can significantly enhance print quality in advanced applications.

Which system is easier to maintain?

Monocular vision systems are generally easier to maintain due to fewer components.

Can I upgrade from monocular to stereo vision later?

In many cases, yes, but compatibility depends on the printer hardware and software architecture.