Firmware Optimization for Visual Positioning UV Printers

Introduction

In the rapidly evolving world of digital printing, visual positioning UV printers stand at the forefront, enabling exceptional precision and quality. Successful operation of these advanced machines hinges not only on their hardware capabilities but also on the efficiency of their firmware. Properly optimized firmware allows printers to deliver high-quality output while maximizing productivity and minimizing downtime. This blog post will explore the fundamentals of firmware optimization for visual positioning UV printers, outlining its benefits, key features, and best practices.

Understanding Firmware and Its Role in UV Printers

Firmware is a specialized type of software embedded directly into a device’s hardware, providing the necessary instructions for the printer to function correctly. In the context of visual positioning UV printers, firmware controls various operations such as:

·

Printer initialization and calibration

·

·

Motor movement and print head positioning

·

·

UV curing processes

·

·

Communication between user interfaces and hardware

·

·

Error handling and diagnostic functions

·

Given its critical role, maintaining up-to-date and optimized firmware is vital for seamless operation.

Benefits of Firmware Optimization

Optimizing firmware can provide numerous benefits that enhance the performance and longevity of visual positioning UV printers. Here are some notable advantages:

1. Improved Print Quality

With optimized firmware, printers can achieve more consistent and accurate results. Enhanced algorithms allow for precise control over the print head's movement and speed, ensuring uniform ink application and reducing defects.

2. Enhanced Efficiency

Optimization can streamline print workflows, resulting in faster production times. By refining processes, such as curing and positioning, printers can complete jobs more quickly without compromising quality.

3. Reduced Downtime

Regular updates and optimizations can help identify and resolve potential issues before they escalate, minimizing unexpected downtime. Efficient error detection and resolution processes contribute to uninterrupted printing operations.

4. Better Resource Management

Optimized firmware can lead to better management of resources, such as ink and power consumption. This not only reduces operational costs but also aligns with environmental sustainability goals by minimizing waste.

5. User-Friendly Operation

Firmware updates can improve the user interface, making it easier for operators to navigate settings and configurations. Enhanced features, such as remote monitoring and diagnostics, empower users to manage printer performance more effectively.

Key Features of Optimized Firmware

Several critical features define a well-optimized firmware for visual positioning UV printers. Understanding these features can assist businesses in selecting the right printer or firmware update strategy.

1. Adaptive Print Head Control

Adaptive control mechanisms help optimize the print head's speed and position in response to varying substrate thicknesses and ink types. This ensures optimal print quality on a diverse range of materials.

2. Smart Curing Algorithms

Innovative curing algorithms allow for real-time adjustments to UV exposure based on environmental conditions and ink characteristics, ensuring flawless adhesion and finish.

3. Comprehensive Diagnostic Tools

Integrated diagnostic tools can monitor printer performance and provide alerts for required maintenance, allowing operators to address issues proactively and maintain optimal uptime.

4. Flexible Communication Protocols

Robust communication protocols allow printers to integrate seamlessly with various design and workflow software, facilitating smoother operations across the entire production process.

5. User-Centric Interface

An intuitive user interface designed with operators in mind enhances usability. Easy access to controls, settings, and troubleshooting resources helps operators manage the printer efficiently.

Best Practices for Firmware Optimization

To take full advantage of firmware optimization for visual positioning UV printers, consider the following best practices:

1. Regular Updates

Keep the printer’s firmware up to date by regularly checking for updates from the manufacturer. New updates can provide important enhancements, new features, and security fixes.

2. Monitor Performance Metrics

Track key performance metrics regularly, such as print quality, speed, and downtime. Analyzing this data can help identify areas that require firmware optimization.

3. Collaborate with Experts

Engaging with the printer manufacturer or software experts can provide valuable insights into specific firmware improvements and support optimal printer performance.

4. Perform Regular Maintenance

Regular maintenance, including cleaning and calibration, significantly contributes to overall printer performance. This maintenance should be aligned with firmware capabilities to ensure compatibility.

5. Train Staff on Optimized Usage

Invest in training for your staff to ensure they understand the capabilities of the updated firmware. Well-trained operators are essential for maximizing the benefits of optimized firmware.

Conclusion

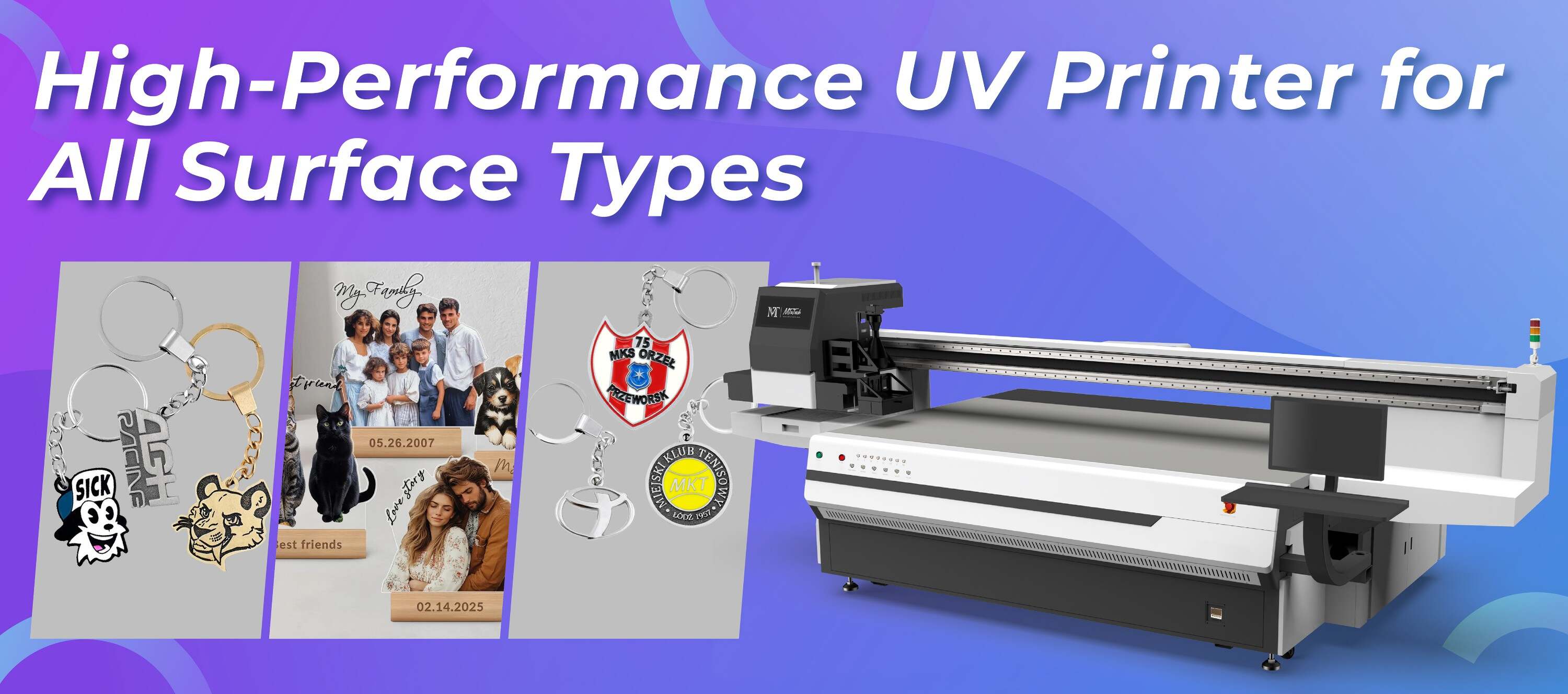

In the competitive landscape of digital printing, ensuring that visual positioning UV printers operate at peak performance is crucial for business success. Firmware optimization plays a significant role in achieving the best possible print quality, efficiency, and reliability. By taking proactive steps in updating, monitoring, and maintaining the firmware, businesses can realize substantial gains in productivity and quality. Explore our high-quality Visual Positioning UV printers here and consider investing in optimized firmware solutions to enhance your operations.

FAQ

What is the role of firmware in a UV printer?

Firmware acts as the interface between the hardware and software of the UV printer, controlling operations like print head movement, UV curing, and error handling to ensure optimal performance.

How often should I update my printer's firmware?

It’s recommended to update your printer's firmware regularly, especially when new versions are released by the manufacturer. Regular updates can improve printer performance and introduce new features.

Can firmware optimization impact print quality?

Yes, optimized firmware can significantly improve print quality by enhancing control over the print head and curing process, leading to more precise and consistent results.

What are common signs that my printer's firmware needs optimization?

Common signs include decreased print quality, an increase in error messages, slower printing speeds, and frequent downtime. Monitoring performance metrics can help identify these issues.

Is professional training necessary for using optimized firmware?

While not mandatory, professional training can greatly enhance staff's ability to utilize optimized firmware effectively, ensuring that the printer operates at its best and minimizes the risk of errors.