How AI Vision Systems Improve UV Printer Registration Accuracy

Introduction

In modern printing environments, accuracy and precision are paramount, especially when it comes to UV printing technology. As businesses seek to enhance their production efficiencies and deliver high-quality outputs, the incorporation of advanced technologies has become indispensable. One of the most groundbreaking enhancements in this realm is the integration of AI vision systems, which significantly improve registration accuracy in UV printers.

This blog post will delve into how AI vision systems contribute to improved registration accuracy, the benefits they offer, and why they are becoming essential in the UV printing landscape.

Understanding UV Printing and Registration Accuracy

What is UV Printing?

UV printing is a process that utilizes ultraviolet light to cure or dry ink as it is printed. This technique allows for high-quality prints on various substrates, including plastics, metals, and paper. The result is vibrant colors, sharp details, and high durability, making UV printing a favorite choice for signage, packaging, and promotional materials.

What is Registration Accuracy?

Registration accuracy refers to the precise alignment of different color layers in the printing process. In UV printing, multiple colors are often applied one after the other, and if they are not perfectly aligned, the final print can suffer from blurriness or color misalignment. Achieving optimal registration accuracy is crucial for maintaining print quality and minimizing waste.

The Role of AI Vision Systems in UV Printing

Definition and Functionality

AI vision systems work through advanced image processing algorithms that allow printers to detect and correct registration errors in real-time. By capturing high-resolution images of the printed substrate, these systems analyze the position of colors and layers, offering adjustments that enhance the final output.

How AI Vision Systems Enhance Registration Accuracy

·

Real-Time Monitoring: AI vision systems continuously monitor the printing process, identifying discrepancies as they occur. This capability enables immediate corrections, preventing defects before they affect production.

·

·

Adaptive Algorithms: The algorithms used in AI vision systems can learn from previous printing runs, adjusting parameters to enhance accuracy in subsequent jobs.

·

·

Multi-Layer Alignment: With the ability to analyze several layers simultaneously, these systems ensure that all colors are perfectly aligned, leading to a more vivid and detailed final output.

·

·

Minimized Waste: By reducing registration errors during the printing process, AI vision systems help businesses save on materials and reduce production costs.

·

Benefits of AI Vision Systems in UV Printing

Increased Efficiency

By automating the registration correction process, AI vision systems reduce the time spent on manual adjustments. This efficiency allows for faster production turnaround times, enabling companies to meet tight deadlines and increase throughput.

Enhanced Print Quality

With improved registration accuracy, prints come out sharper and more vibrant. Customers are more likely to be satisfied with high-quality outcomes, leading to increased repeat business and referrals.

Cost-Effectiveness

Investing in AI vision systems might require an initial financial outlay, but the long-term savings can be substantial. Reduced waste, fewer defective prints, and streamlined operations contribute to a healthier bottom line.

Flexibility and Versatility

AI vision systems can adapt to a variety of substrates and printing conditions, making them ideal for businesses that work with multiple materials or print unique designs. Their intelligent algorithms can be trained for specific jobs, ensuring that even complex projects achieve high fidelity.

Features of AI Vision Systems in UV Printers

High-Resolution Imaging

These systems utilize advanced cameras capable of capturing images at high resolutions, ensuring detailed analysis of print layers and substrates. The clarity in imaging translates to precision in adjustments.

Advanced Processing Algorithms

The processing capabilities of AI vision systems are engineered to handle large data volumes quickly. This allows for real-time adjustments based on live feedback from the printing process.

User-Friendly Interfaces

Many AI vision systems come equipped with intuitive interfaces that allow operators to monitor processes, make adjustments, and generate reports with ease. This reduces the learning curve for new staff and improves overall operational efficiency.

Integration with Existing Systems

AI vision systems can seamlessly integrate with existing UV printing equipment, minimizing the disruption to current workflows. Whether upgrading a legacy system or investing in new technology, integration enhances functionality without necessitating a complete overhaul.

Future Trends in AI Vision Systems and UV Printing

Continued Technological Advancement

The field of AI and image processing is rapidly evolving. Future developments may include enhanced predictive algorithms that not only correct mistakes but anticipate them, making the printing process even more robust.

Greater Customization Options

As AI vision systems become more advanced, they will offer even more customization options for businesses. This means that printers can tailor their processes specifically to the needs of their clients, leading to more bespoke services.

Environmental Considerations

With an increased emphasis on sustainability, future AI vision systems may incorporate eco-friendly practices, such as optimizing ink usage and reducing waste, contributing to greener printing processes.

Conclusion

The integration of AI vision systems into UV printing technology marks a significant leap forward in achieving registration accuracy. The benefits—including increased efficiency, enhanced print quality, and cost-effectiveness—provide a compelling case for businesses looking to stay competitive in a rapidly evolving market.

Moreover, as technology continues to advance, the potential for AI vision systems to improve and adapt will only grow. For businesses aiming to enhance their UV printing processes, embracing this technology could be the key to staying ahead of the competition and meeting increasing customer demands.

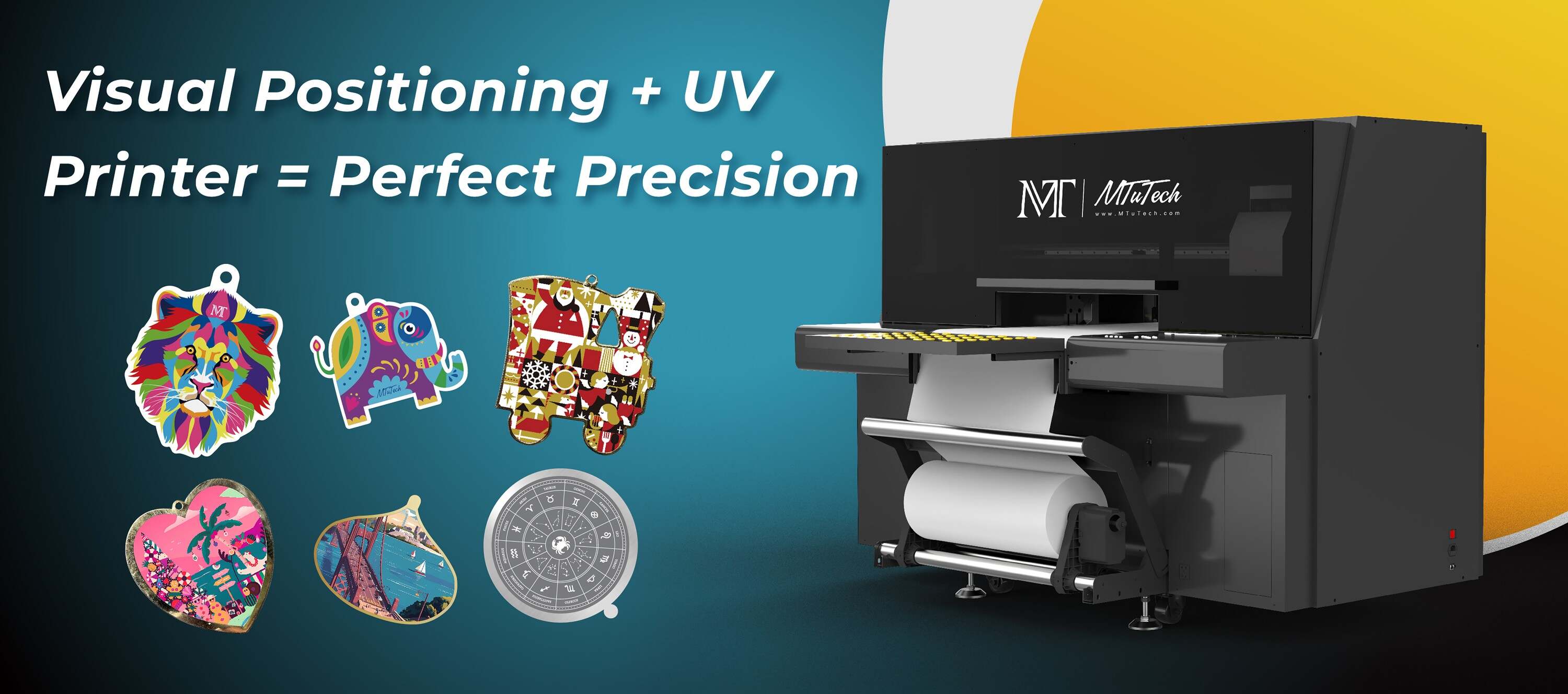

To discover how you can elevate your UV printing capabilities, explore our high-quality Visual Positioning UV printers here.

FAQ

What is the primary function of AI vision systems in UV printing?

The primary function of AI vision systems in UV printing is to improve registration accuracy by automatically detecting misalignments and making real-time adjustments to ensure precise color layering.

Can AI vision systems work with various substrates?

Yes, AI vision systems are versatile and can adapt to different substrates, which makes them suitable for a wide range of printing applications and materials.

How do AI vision systems reduce waste in UV printing?

By ensuring accurate registration during the printing process, AI vision systems minimize the number of defective prints, thereby reducing material waste and associated costs.

Are AI vision systems easy to integrate with existing printing equipment?

Most AI vision systems are designed for easy integration with existing UV printing equipment, allowing businesses to upgrade their technology without complete system overhauls.

What future advancements can we expect in AI vision systems for printing?

Future advancements may include enhanced predictive algorithms, greater customization for specific client needs, and features focused on sustainability and environmental impact reduction in the printing process.