Understanding Edge Lighting in Printing Systems

What Is Edge Lighting?

Edge lighting is an illumination technique where light is directed across the surface or edges of a printed object rather than shining directly onto it from above. Unlike conventional overhead lighting, edge lighting emphasizes surface textures, contours, and boundaries by creating controlled shadows and highlights.

In printing environments, this approach makes even subtle defects visible—defects that might remain undetected under flat or diffuse lighting conditions. Scratches, misregistrations, ink spread, embossing errors, and material distortions become far easier to identify when illuminated from the edge.

Why Traditional Lighting Falls Short

Standard lighting systems often flood the print area with uniform light. While this is useful for general visibility, it tends to flatten the visual field, making it difficult to distinguish fine variations in surface height, ink thickness, or alignment.

Edge lighting, on the other hand, introduces contrast through directionality. This contrast is critical for machine vision systems and human operators alike, as it reveals features that would otherwise blend into the background.

The Science Behind Edge Lighting

Edge lighting relies on a combination of optical principles that work together to enhance visual detection:

Directional Illumination

Light is projected at a shallow angle across the print surface. This grazing angle causes raised or recessed areas to cast micro-shadows, highlighting imperfections with remarkable clarity.

Contrast Amplification

By emphasizing edges and transitions, edge lighting increases contrast between printed elements and the substrate. This makes boundaries, text edges, and registration marks stand out more clearly.

Controlled Reflection

Printed materials often have reflective or semi-gloss surfaces. Edge lighting minimizes harsh reflections and glare by preventing light from bouncing directly back into the camera or viewer.

Uniform Light Distribution

High-quality edge lighting systems use precision-engineered LED arrays to ensure consistent illumination across the inspection area. This uniformity is essential for accurate detection and repeatable results.

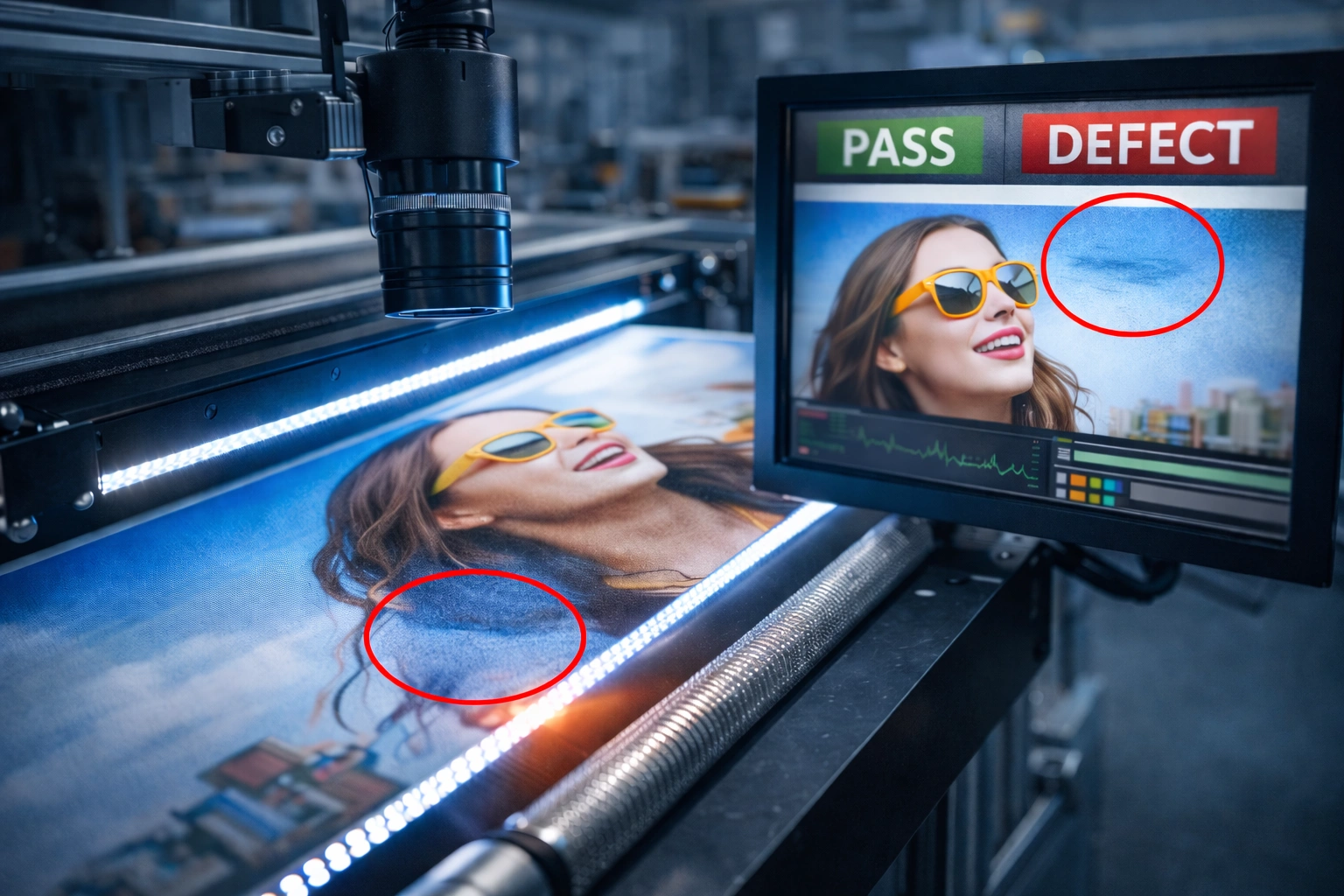

Role of Edge Lighting in Visual Print Detection

Visual print detection systems depend heavily on image clarity. Cameras and sensors can only analyze what they can clearly see, and edge lighting significantly improves the quality of captured images.

Enhancing Edge Definition

Clear edge definition is critical for detecting misalignment, skewing, and registration errors. Edge lighting sharpens these boundaries, allowing vision systems to compare printed output against digital references with greater accuracy.

Improving Defect Recognition

Defects such as smudging, ink pooling, pinholes, or substrate deformation are often subtle. Edge lighting exaggerates these flaws visually, making them easier to identify during automated or manual inspection.

Supporting Real-Time Monitoring

In high-speed production environments, inspections must occur in real time. Edge lighting ensures that vision systems receive consistent, high-contrast images even at fast print speeds.

Key Benefits of Edge Lighting in Print Inspection

1. Superior Print Quality Control

Edge lighting enables earlier and more accurate detection of print defects. By identifying issues during production rather than after completion, printers can correct problems immediately and prevent large-scale waste.

2. Reduced Material Waste

Misprints and rejected batches are costly. By improving defect visibility, edge lighting helps reduce scrap rates and lowers overall material consumption.

3. Faster Inspection Processes

Clearer visuals mean faster decision-making. Operators and automated systems can identify defects quickly, reducing inspection time and improving production throughput.

4. Improved Color and Ink Consistency

Edge lighting makes variations in ink density and color coverage more apparent, helping maintain consistent output across long print runs.

5. Enhanced Accuracy in Registration Detection

Precise alignment is essential in multi-layer and multi-pass printing. Edge lighting improves the visibility of registration marks and edges, ensuring accurate layer placement.

6. Cost-Effective Quality Assurance

While edge lighting systems require an initial investment, the long-term savings from reduced waste, fewer reprints, and improved efficiency often outweigh the costs.

Applications of Edge Lighting Across Printing Industries

Packaging and Label Printing

In packaging, visual appeal and precision are non-negotiable. Edge lighting helps detect misaligned graphics, uneven varnish layers, and embossing defects that could compromise brand presentation.

Commercial and Digital Printing

For brochures, posters, and marketing materials, edge lighting ensures crisp text, sharp images, and consistent color reproduction.

Industrial Printing

Industrial components often require functional markings, barcodes, or serial numbers. Edge lighting improves the detection of incomplete or distorted prints that could affect traceability.

Textile and Fabric Printing

Fabric surfaces are inherently uneven. Edge lighting helps identify misalignment, ink bleeding, and pattern distortion on textiles, enabling better quality control.

Signage and Large-Format Printing

Large-format prints must remain consistent across wide surfaces. Edge lighting assists in identifying banding, streaks, and alignment errors over extended print areas.

Integration of Edge Lighting with Vision Systems

Hardware Integration

Edge lighting is typically installed around the inspection zone using LED strips or modular lighting units. These are positioned to deliver consistent illumination without interfering with print heads or material movement.

Camera Synchronization

Lighting systems are synchronized with high-resolution cameras to ensure optimal exposure and image clarity. This synchronization is crucial for accurate defect detection.

Software Analysis

Captured images are processed using vision algorithms that compare them against predefined quality standards. Edge lighting enhances the accuracy of these algorithms by improving image contrast and detail.

Training and Operational Considerations

Operator Training

While edge lighting systems are user-friendly, operators must be trained to interpret enhanced visuals correctly. Understanding what constitutes a defect versus an acceptable variation is essential.

Calibration and Maintenance

Regular calibration ensures consistent lighting intensity and angle. LEDs have long lifespans, but periodic checks help maintain inspection accuracy.

Customization for Different Materials

Different substrates reflect light differently. Adjustable edge lighting allows customization based on material type, ensuring optimal performance across applications.

Real-World Impact: Practical Examples

Packaging Manufacturer Improvement

A packaging company struggling with inconsistent alignment implemented edge lighting in its inspection line. Within weeks, defect detection accuracy improved significantly, and material waste was reduced by over 20%.

Textile Printing Optimization

A textile printer facing frequent pattern misalignment integrated edge lighting with its vision system. Real-time detection allowed immediate adjustments, resulting in improved consistency and higher customer satisfaction.

Edge Lighting vs Conventional Lighting Systems

| Feature | Conventional Lighting | Edge Lighting |

|---|---|---|

| Defect Visibility | Moderate | High |

| Edge Detection | Limited | Excellent |

| Glare Control | Poor | Controlled |

| Inspection Speed | Slower | Faster |

| Waste Reduction | Minimal | Significant |

This comparison highlights why edge lighting is becoming the preferred choice for advanced print inspection systems.

Future Trends in Edge Lighting Technology

Smart Adaptive Lighting

Future systems will automatically adjust lighting angles and intensity based on material type and print complexity.

AI-Driven Inspection

When combined with artificial intelligence, edge lighting will enable predictive defect detection and automated quality optimization.

Compact Modular Designs

Newer lighting modules are becoming smaller and more energy-efficient, making integration easier even in compact printing setups.

Conclusion

Edge lighting has emerged as a powerful tool in modern visual print detection. By enhancing contrast, improving defect visibility, and supporting real-time inspection, it addresses many of the challenges faced by today’s printing operations. Its ability to reduce waste, improve quality, and increase efficiency makes it a valuable investment for businesses aiming to remain competitive in an increasingly demanding market.

As printing technology continues to evolve, edge lighting will play an even more critical role in ensuring precision, consistency, and reliability. For printers seeking to upgrade their quality control capabilities, integrating edge lighting into visual inspection systems is no longer optional—it is essential.

explore our high-quality Visual Positioning uv printers here to take advantage of these innovative features.

Frequently Asked Questions (FAQ)

What is edge lighting in printing?

Edge lighting is a directional illumination technique that highlights edges, textures, and surface variations to improve defect detection in printed materials.

How does edge lighting improve visual print detection?

By increasing contrast and emphasizing boundaries, edge lighting makes defects like misalignment, ink inconsistencies, and surface flaws easier to detect.

Is edge lighting suitable for all printing materials?

Yes, it can be adapted for paper, plastic, fabric, and other substrates by adjusting light intensity and angle.

Does edge lighting increase production costs?

While there is an initial setup cost, long-term savings from reduced waste and improved efficiency typically outweigh the investment.

Do operators need special training?

Basic training is recommended to help operators correctly interpret enhanced visuals and make informed adjustments during production.