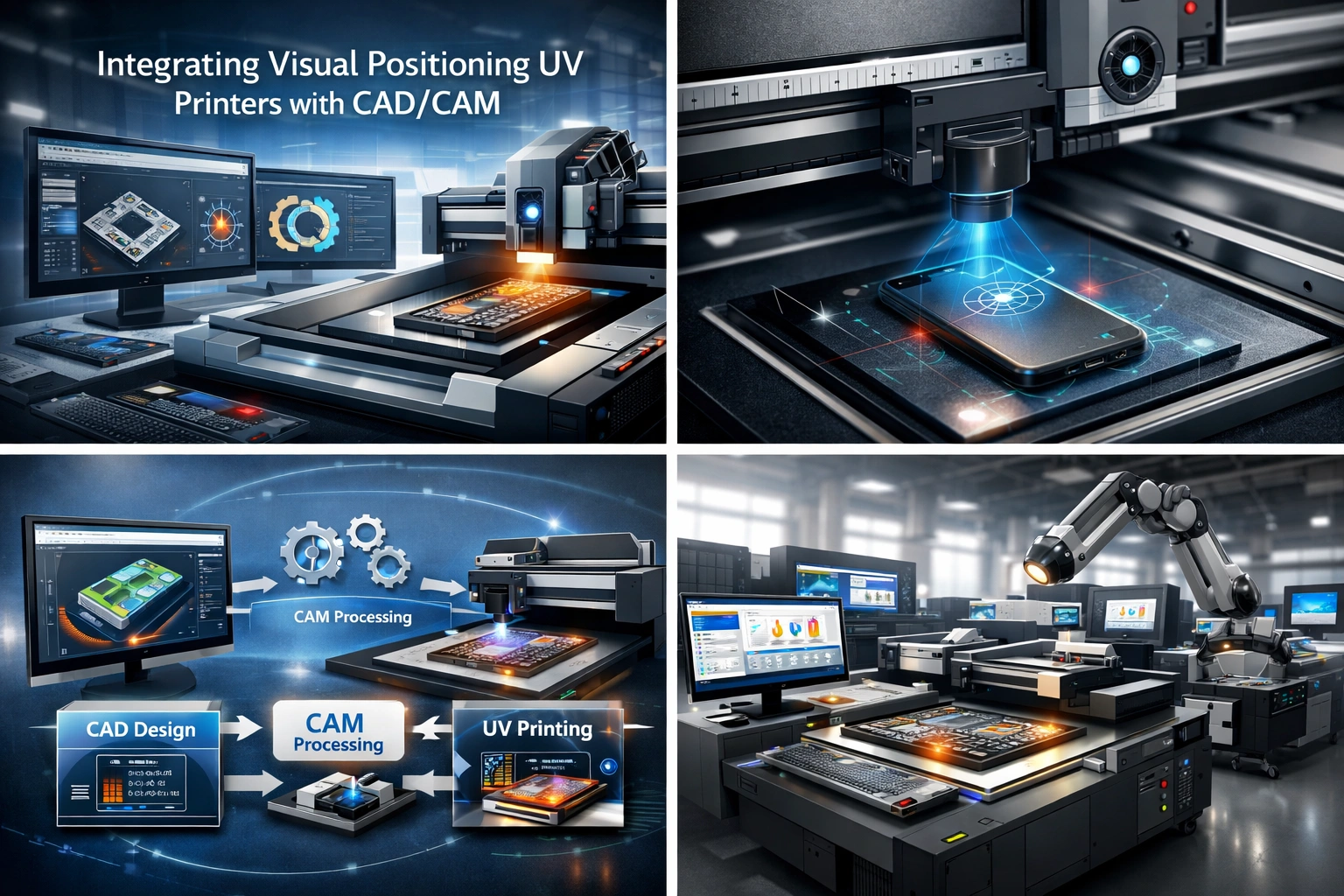

Integrating Visual Positioning UV Printers with CAD/CAM

The digital manufacturing and printing industries are evolving at an unprecedented pace. As customer demand shifts toward customization, faster turnaround times, and higher accuracy, businesses must adopt smarter and more connected production workflows. One of the most impactful advancements in this space is the integration of Visual Positioning UV printers with CAD/CAM systems.

Visual Positioning UV printers bring precision printing to irregular, pre-shaped, or pre-printed objects, while CAD/CAM systems streamline the design and manufacturing process through automation and accuracy. When these two technologies work together, they create a seamless digital-to-physical workflow that significantly enhances productivity, reduces waste, and improves output quality.

This article explores how to successfully integrate Visual Positioning UV printers with CAD/CAM systems, the technical considerations involved, workflow optimization strategies, real-world benefits, and best practices to ensure long-term success. Whether you operate a print shop, manufacturing facility, or customization business, this guide will help you build a future-ready production environment.

Understanding Visual Positioning UV Printers

Visual Positioning UV printers are advanced digital printing machines designed to print with extreme accuracy on a wide range of substrates. Unlike conventional UV printers, these systems use camera-based vision technology to detect the exact position, orientation, and contours of the object being printed.

By analyzing real-time visual data, the printer automatically adjusts print placement, ensuring perfect alignment even on non-standard shapes or variable layouts. UV inks are instantly cured using ultraviolet light, allowing printing on materials that traditionally posed challenges for ink adhesion.

Key Characteristics of Visual Positioning UV Printers

Camera-based alignment for precise print placement

Instant UV ink curing, enabling fast production

Support for rigid and irregular substrates

High-resolution output with sharp edges and vibrant colors

Minimal setup time for short or variable runs

This combination makes Visual Positioning UV printers ideal for industries focused on customization, personalization, and short-run production.

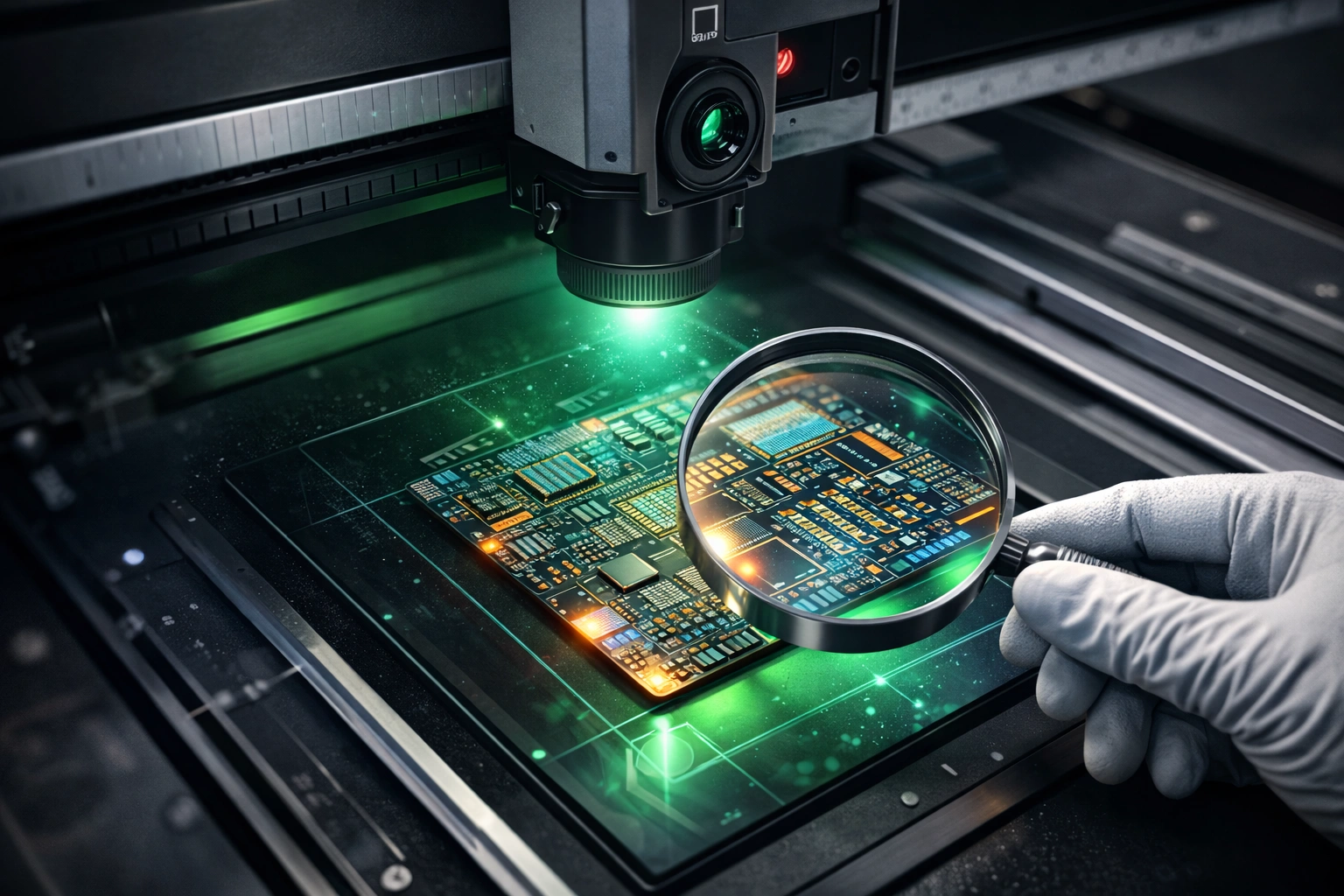

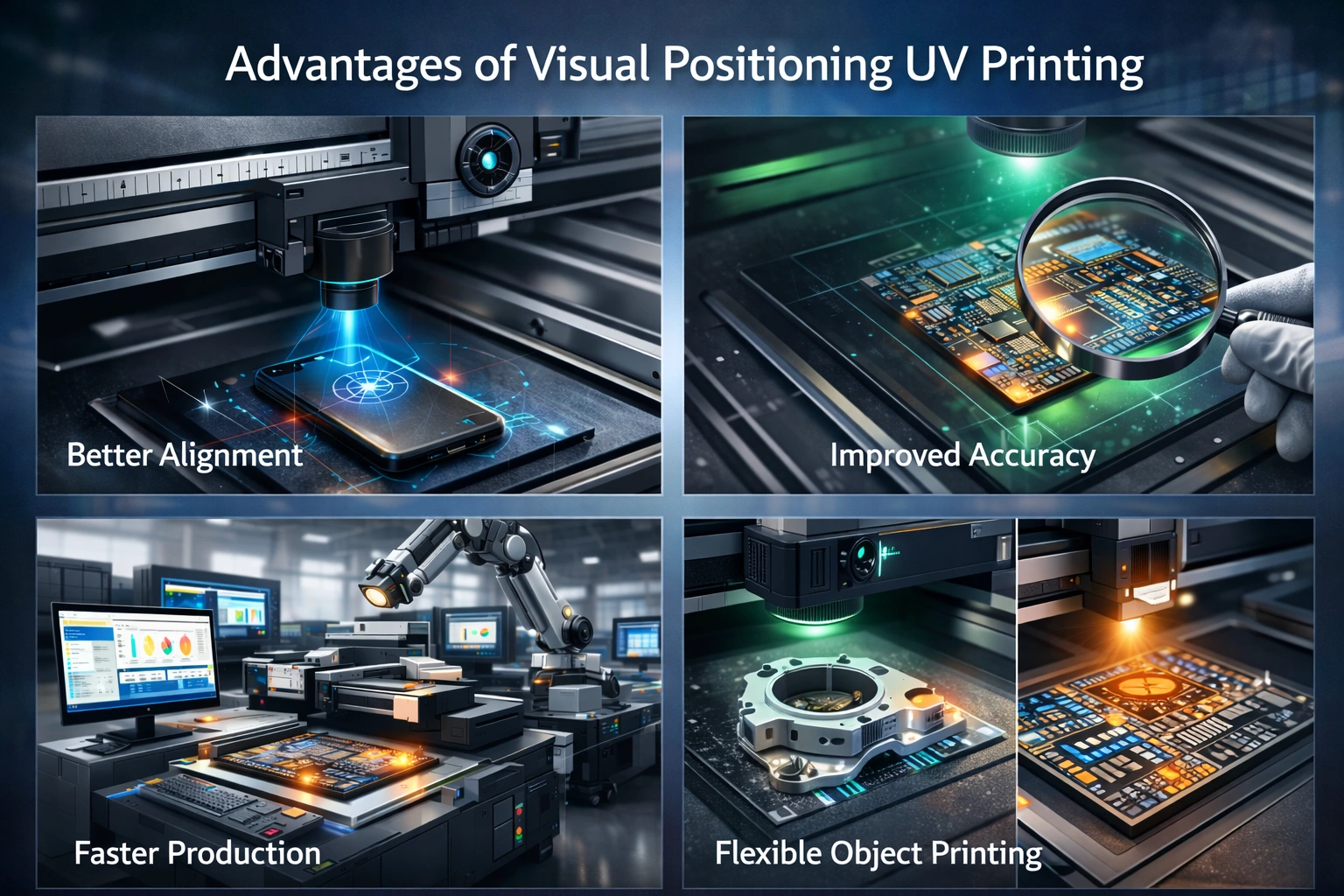

Advantages of Visual Positioning UV Printing

Integrating Visual Positioning UV printing into a modern production workflow offers several measurable benefits.

Material Versatility

These printers can handle materials such as glass, acrylic, metal, wood, leather, plastic, ceramics, and coated fabrics. This flexibility opens opportunities across signage, packaging, industrial parts, promotional products, and décor.

Precision and Consistency

Vision systems eliminate manual alignment errors, ensuring consistent output even across large batches or mixed designs.

Production Speed

UV ink curing happens instantly, removing the need for drying time and enabling faster job completion.

Durability of Prints

UV-cured inks are resistant to moisture, fading, chemicals, and abrasion, making them suitable for both indoor and outdoor applications.

Reduced Waste

Accurate positioning minimizes misprints, saving material costs and improving sustainability.

Overview of CAD/CAM Systems

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems form the digital backbone of modern manufacturing environments.

CAD Systems

CAD software is used to create precise digital designs, technical drawings, and layouts. Designers can control dimensions, shapes, layers, colors, and tolerances with exceptional accuracy.

CAM Systems

CAM software translates CAD designs into machine-readable instructions. These instructions guide machines on how to execute tasks such as cutting, engraving, milling, or printing.

Why CAD/CAM Matters in Printing

When integrated with printing systems, CAD/CAM software ensures that what is designed digitally is produced accurately in the physical world, with minimal interpretation or manual intervention.

Benefits of CAD/CAM Integration

Improved accuracy by eliminating manual data transfer

Faster production cycles through automation

Easy design modifications without restarting workflows

Lower operational costs due to reduced errors

Better scalability for high-volume or customized production

When combined with Visual Positioning UV printers, CAD/CAM systems elevate printing from a standalone process to a fully automated manufacturing solution.

Why Integration Is Essential

Standalone machines and disconnected software systems create inefficiencies, data duplication, and human error. Integration bridges the gap between design and production, creating a single source of truth for every job.

Key reasons integration is critical:

Increasing demand for personalized products

Rising labor costs requiring automation

Need for consistent quality across batches

Pressure to reduce turnaround times

Growing complexity of print layouts and materials

A connected CAD/CAM and UV printing ecosystem ensures that businesses remain competitive and scalable.

Step-by-Step Integration Process

1. Assess Business Requirements

Before integrating systems, evaluate your production needs carefully.

Consider:

Types of products you print

Substrate shapes and sizes

Design complexity

Daily or monthly production volume

Level of customization required

This assessment helps determine the level of integration needed and prevents unnecessary investment.

2. Select Compatible CAD/CAM Software

Not all CAD/CAM platforms are optimized for printing workflows. Choose software that supports:

Vector and raster file formats

Accurate scaling and dimension control

Layer-based design management

Export compatibility with UV printer RIP software

Color profile and ICC support

Software compatibility ensures smooth data flow from design to print.

3. Ensure Printer Software Compatibility

The printer’s control software must be capable of:

Importing CAD-generated files

Interpreting vector paths and print zones

Mapping visual positioning data to design coordinates

Communicating with CAM instructions

In many cases, a RIP (Raster Image Processor) acts as the bridge between CAD/CAM output and the printer hardware.

4. Configure Hardware Communication

Integration requires stable communication between systems.

Key steps include:

Network setup for printer and workstation

Driver installation and firmware configuration

Camera calibration for accurate object detection

Synchronization of coordinate systems

Proper hardware configuration ensures that visual data aligns perfectly with design files.

5. Establish a Unified Workflow

A standardized workflow prevents confusion and errors.

Typical workflow:

Design creation in CAD software

Design validation and export

CAM processing and toolpath or print path generation

File transfer to printer software

Vision system alignment and verification

UV printing execution

Quality inspection

Documenting this workflow ensures consistency across teams.

6. Implement Quality Control Checkpoints

Quality assurance should be built into the process.

Monitor:

Print alignment accuracy

Color consistency

Ink adhesion

Substrate positioning

Reprint frequency

Automated checks reduce rework and protect brand reputation.

7. Train Operators and Designers

Even the most advanced system fails without skilled operators.

Training should cover:

CAD design best practices for printing

CAM output optimization

Printer calibration and maintenance

Troubleshooting alignment or file errors

Cross-functional knowledge improves collaboration between design and production teams.

Optimizing Performance After Integration

Integration is not a one-time task; it requires ongoing optimization.

Data-Driven Improvements

Track key metrics such as:

Print accuracy rate

Job completion time

Material waste percentage

Machine downtime

Use these insights to refine workflows and improve efficiency.

Automation Opportunities

Advanced integrations allow:

Automated job queuing

Batch processing of designs

Variable data printing

Real-time production monitoring

Automation reduces dependency on manual intervention.

Maintenance and Updates

Regularly update:

CAD/CAM software

Printer firmware

Vision system calibration parameters

This ensures compatibility, security, and performance improvements.

Common Challenges and Solutions

File Compatibility Issues

Solution: Standardize file formats and naming conventions across teams.

Alignment Errors

Solution: Regular camera calibration and substrate positioning checks.

Color Inconsistency

Solution: Use calibrated monitors, consistent color profiles, and controlled lighting.

Workflow Bottlenecks

Solution: Analyze data logs and automate repetitive tasks.

Industry Applications

Integrated Visual Positioning UV printing with CAD/CAM systems is widely used in:

Customized packaging

Industrial component marking

Promotional products

Signage and displays

Consumer electronics branding

Interior décor and furniture printing

Each application benefits from accuracy, repeatability, and speed.

Future Trends

The future of CAD/CAM and UV printing integration includes:

AI-assisted design validation

Predictive maintenance using machine data

Cloud-based workflow management

Smart factories with end-to-end automation

Early adopters gain a significant competitive advantage.

Conclusion

Integrating Visual Positioning UV printers with CAD/CAM systems is no longer optional for businesses aiming to stay competitive in modern manufacturing and printing. This integration creates a seamless, accurate, and efficient workflow that bridges design and production while reducing errors, waste, and turnaround time.

By selecting compatible software, configuring hardware correctly, training teams, and continuously optimizing processes, businesses can unlock the full potential of their equipment. The result is higher quality output, improved scalability, and greater customer satisfaction.

A well-executed integration is not just a technical upgrade—it is a strategic investment in long-term growth and operational excellence.

explore our high-quality Visual Positioning UV printers here.

Frequently Asked Questions

What materials work best with Visual Positioning UV printers?

These printers support glass, metal, wood, plastic, acrylic, leather, ceramics, and coated surfaces.

Do CAD/CAM systems require customization for UV printing?

In many cases, yes. Workflow adjustments and software configuration improve compatibility and performance.

Is integration suitable for small businesses?

Absolutely. Even small print shops benefit from reduced waste, faster production, and better consistency.

How long does integration take?

Depending on system complexity, it can range from a few days to several weeks.

Does integration reduce operating costs?

Yes. Automation, accuracy, and reduced reprints significantly lower long-term costs.