How to Stay Ahead in 2025 with Visual Positioning Print Technology

Introduction

As we embark on a new era of printing technology, staying competitive in the marketplace requires an understanding of the latest innovations. One such breakthrough is Visual Positioning Print Technology (VPPT), which is revolutionizing how businesses approach design and printing. With its ability to enhance precision, reduce waste, and improve overall efficiency, adopting VPPT can propel your business to new heights in 2025.

Understanding Visual Positioning Print Technology

Visual Positioning Print Technology utilizes advanced imaging systems and sensors to ensure accurate placement of print material. By merging digital information with physical prints, VPPT enables seamless integration of graphics that align with actual production processes. This technology is designed to increase efficiency while minimizing errors in printing and production.

Key Features of VPPT

·

Real-time Monitoring: Continuous tracking and adjustments during the printing process to maintain high precision.

·

·

Enhanced Color Accuracy: Improved color matching capabilities to ensure that printed designs resemble digital prototypes accurately.

·

·

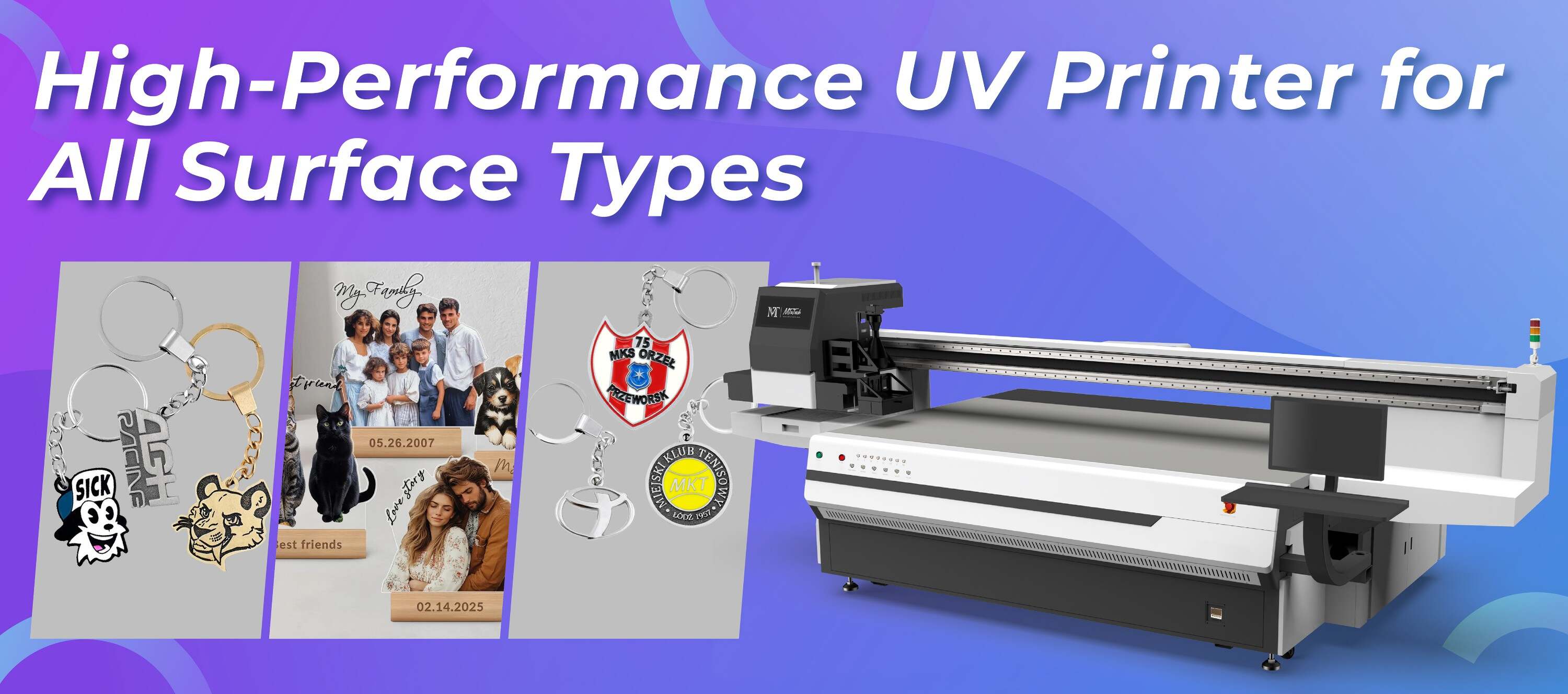

Material Versatility: Ability to print on a variety of surfaces, including rigid, flexible, and textured materials.

·

·

Automated Adjustments: Automated systems that modify printing parameters according to the material's behavior.

·

·

Data-Driven Insights: Utilization of data analytics to optimize production workflows and reduce waste.

·

Benefits of Adopting VPPT in Your Business

In a world where consumer preferences are constantly evolving, leveraging Visual Positioning Print Technology can offer significant advantages. Below are some of the major benefits of adopting VPPT:

1. Increased Efficiency and Productivity

With real-time monitoring and automated adjustments, VPPT drastically reduces downtime and increases the speed of production. This means businesses can fulfill orders faster, leading to improved customer satisfaction and the ability to take on larger projects without compromising quality.

2. Reduced Waste

One of the key challenges in traditional printing methods is material waste. VPPT minimizes excess material usage through precise alignment and real-time adjustments, allowing businesses to maximize their resources and reduce overall costs associated with waste disposal.

3. Flexibility in Design Implementation

The versatility of materials that VPPT can handle allows businesses to experiment with new design concepts without being constrained by printing limitations. This freedom can spark creativity and enable brands to create unique offerings that stand out in a competitive marketplace.

4. Cost Effectiveness

While the initial investment in VPPT technology may seem significant, the long-term cost savings often outweigh the initial expenses. Reduced waste, increased efficiency, and enhanced productivity all contribute to a more cost-effective production process.

5. Improved Quality Assurance

Visual Positioning Print Technology ensures higher quality outputs through its advanced color matching and automated systems. This means that businesses can deliver exceptional quality consistently, further enhancing their reputations and customer loyalty.

How to Implement VPPT in Your Business

To successfully integrate Visual Positioning Print Technology into your existing operations, consider the following steps:

1. Assess Your Current Workflow

Before diving into new technology, evaluate your current printing workflow. Identify bottlenecks, inefficiencies, and areas for improvement that VPPT can address.

2. Choose the Right Equipment

Investing in high-quality printing equipment is crucial for success. Look for printers that explicitly incorporate Visual Positioning technology, ensuring they meet the unique demands of your operations. Explore our high-quality Visual Positioning UV printers here.

3. Train Your Team

Once your new equipment is in place, it’s vital to train your team to use the technology effectively. Comprehensive training will help your staff understand the capabilities of VPPT and how to leverage it to enhance their workflow.

4. Continuously Evaluate and Optimize

After implementing VPPT, continually evaluate its effectiveness in your processes. Solicit feedback from your team and analyze performance metrics to identify areas for further improvement.

Case Studies: Businesses Thriving with VPPT

Several companies across various sectors have successfully integrated Visual Positioning Print Technology into their operations, leading to impressive results:

1. Print Packaging Solutions

A leading print packaging provider adopted VPPT to streamline their production process. As a result, they were able to reduce production time by 30% and increased their profit margins by 25% within the first year of implementation.

2. Custom Merchandise Retailer

A custom merchandise retailer used VPPT to enhance their design capabilities. The technology allowed them to offer customers a wider variety of products and quicker turnaround times, resulting in a 40% increase in customer orders over six months.

Challenges to Consider

While VPPT comes with numerous benefits, it’s essential to be aware of potential challenges that may arise during the transition:

·

Initial Investment: The upfront costs of purchasing or upgrading to VPPT equipment can be significant.

·

·

Training Requirements: Staff may require extensive training to fully harness the potential of the new technology.

·

·

Integration with Existing Systems: Merging VPPT with legacy systems can pose technical difficulties, necessitating careful planning.

·

Conclusion

As we move into 2025, businesses looking to stay competitive must consider adopting innovative technologies like Visual Positioning Print Technology. By leveraging its numerous benefits—including increased efficiency, reduced waste, and improved quality—companies can not only boost their productivity but also enhance customer satisfaction. Investing in VPPT now ensures you remain ahead of the curve and are well-equipped to meet the dynamic demands of the marketplace.

FAQ

What is Visual Positioning Print Technology?

Visual Positioning Print Technology is an advanced printing method that uses imaging systems and sensors to ensure accurate placement of print designs, improving efficiency and quality in the printing process.

How can VPPT reduce waste in printing?

VPPT minimizes waste by enabling precise alignment and real-time adjustments during the printing process, which allows for more efficient use of materials.

Is VPPT suitable for all types of printing applications?

Yes, VPPT is versatile and can be used across various printing applications, making it suitable for a wide range of materials and designs.

What should I consider before implementing VPPT?

You should assess your current workflow, evaluate your budget for new equipment, train your team, and plan for integration with any existing systems.

Can small businesses benefit from VPPT technology?

Absolutely! Small businesses can see significant gains in efficiency, customer satisfaction, and overall competitiveness by adopting VPPT technology.