Visual Positioning UV Printing for Modern Promotional Production

The promotional printing industry has changed dramatically over the last decade. Clients no longer demand only high-quality output; they expect speed, flexibility, short turnaround times, and the ability to personalize products in small quantities without compromising precision. For print studios that rely on traditional flatbed UV printing workflows, meeting these expectations has become increasingly difficult. Manual setup processes, physical jigs, repeated test prints, and alignment errors create bottlenecks that limit profitability and scalability.

This challenge is particularly evident for studios handling pre-fabricated promotional items such as acrylic stands, leather covers, wooden signage, and presentation accessories. These items are rarely uniform in shape or size, making manual alignment both time-consuming and error-prone. As competition increases and margins shrink, print businesses must adopt smarter technologies to remain relevant.

This article explores how visual positioning UV printing is redefining promotional product manufacturing through a real-world implementation at Urban Canvas Prints, a modern print studio based in Manchester. By integrating the MTuTech Visual Positioning UV Printer 9060, the studio transformed inefficiencies into a streamlined, highly profitable production workflow.

The Complexity of Modern Promotional Printing

Promotional products are no longer simple flat prints. Today’s market includes a wide range of pre-cut, shaped, and textured items that must be printed with absolute accuracy. Examples include:

Smartphone stands with irregular contours

Leather notebook and card covers

Acrylic desk organizers

Pre-cut MDF signage

Award plaques and trophies with existing engravings

Each product introduces new alignment challenges. Unlike raw sheets, these items cannot be easily squared or positioned against fixed rulers. Even a millimeter of misalignment can ruin a premium product, especially when printing names, dates, or logos over existing features.

For studios processing dozens of different items daily, manual positioning becomes unsustainable.

Urban Canvas Prints: Business Overview

Urban Canvas Prints is a dynamic print studio serving local businesses, event organizers, marketing agencies, and creative professionals. Their specialization lies in custom, short-to-medium-run promotional products, a segment where flexibility and speed are critical.

Rather than mass-producing identical items, the studio focuses on:

Limited-run event merchandise

Product launch giveaways

Branded office accessories

Personalized awards and recognition items

This business model thrives on variety but suffers when setup times outweigh production value.

The Core Operational Challenge

Before upgrading their workflow, Urban Canvas Prints relied on a standard flatbed UV printer. While capable of producing high-quality prints, the system lacked intelligence when it came to object recognition and positioning.

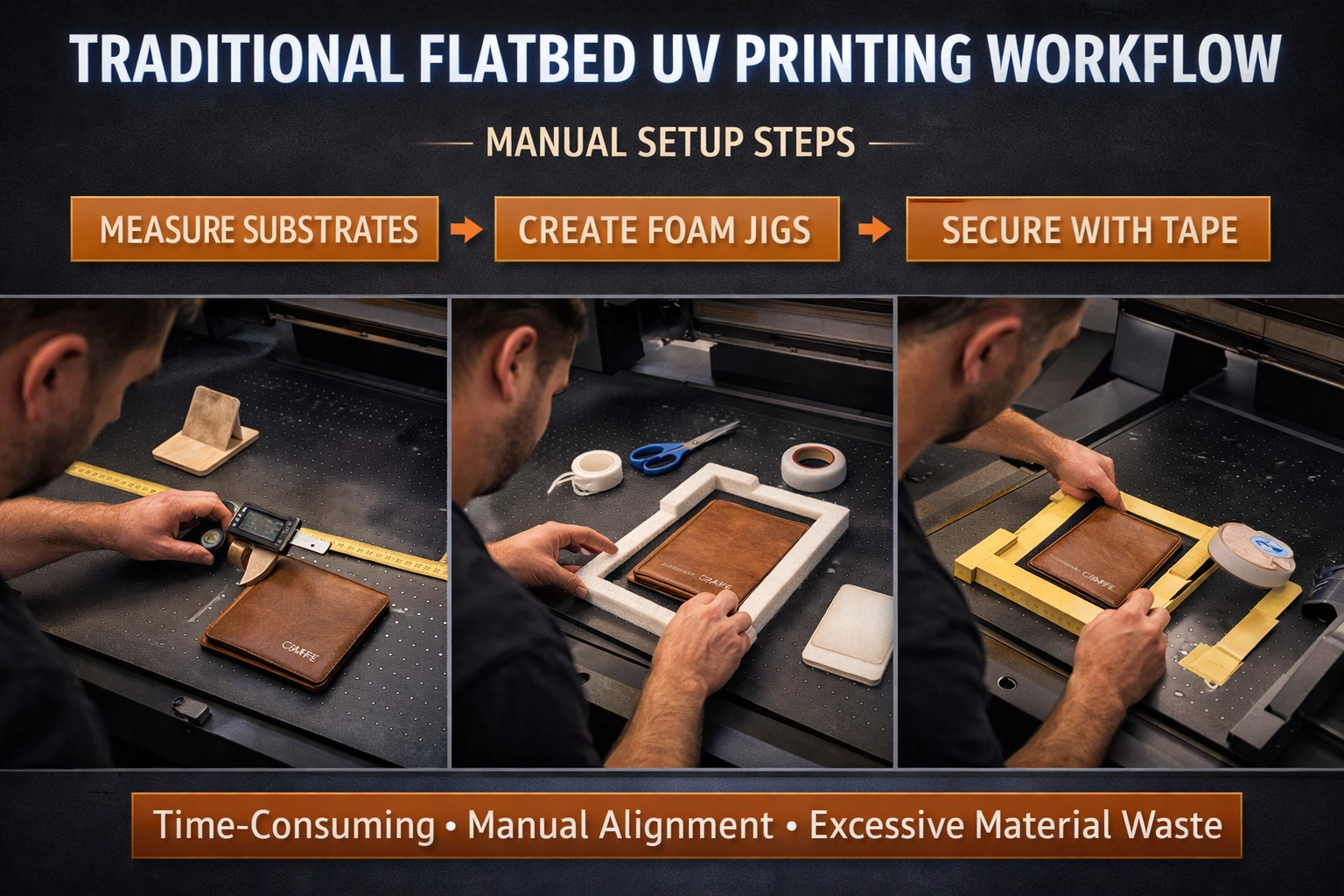

Manual Setup Bottlenecks

For every new batch, operators had to:

Measure each substrate manually

Build foam jigs or tape barriers

Align items by hand

Run multiple test prints

Adjust files repeatedly

Each setup took 15 to 20 minutes, even for small batches. This was manageable for large orders but disastrous for short runs.

Financial Impact of Inefficiency

Small orders, such as 30–50 customized items, became unprofitable due to:

Excessive non-billable setup time

Material waste from misprints

Operator fatigue and errors

Jobs requiring perfect registration—such as printing names onto pre-engraved awards—were often rejected entirely due to risk.

Why Traditional Flatbed Printing Falls Short

Conventional flatbed UV printers assume that substrates are:

Uniform

Square or rectangular

Precisely positioned

In reality, promotional items rarely meet these conditions. Traditional systems lack the ability to “see” objects on the bed, forcing operators to compensate manually.

Key limitations include:

No automatic object detection

No correction for rotation or offset

Dependence on physical jigs

High setup waste

Inconsistent repeatability

These limitations directly restrict scalability and innovation.

The Shift to Visual Positioning UV Printing

To overcome these constraints, Urban Canvas Prints invested in the MTuTech Visual Positioning UV Printer 9060, a machine designed specifically for precision printing on irregular objects.

Why the 90×60 cm Format Matters

The 9060 format offered an ideal balance:

Large enough to process multiple items in one run

Compact enough for daily promotional workloads

Optimized for mixed-batch production

This size allowed the studio to gang different products together without compromising accuracy.

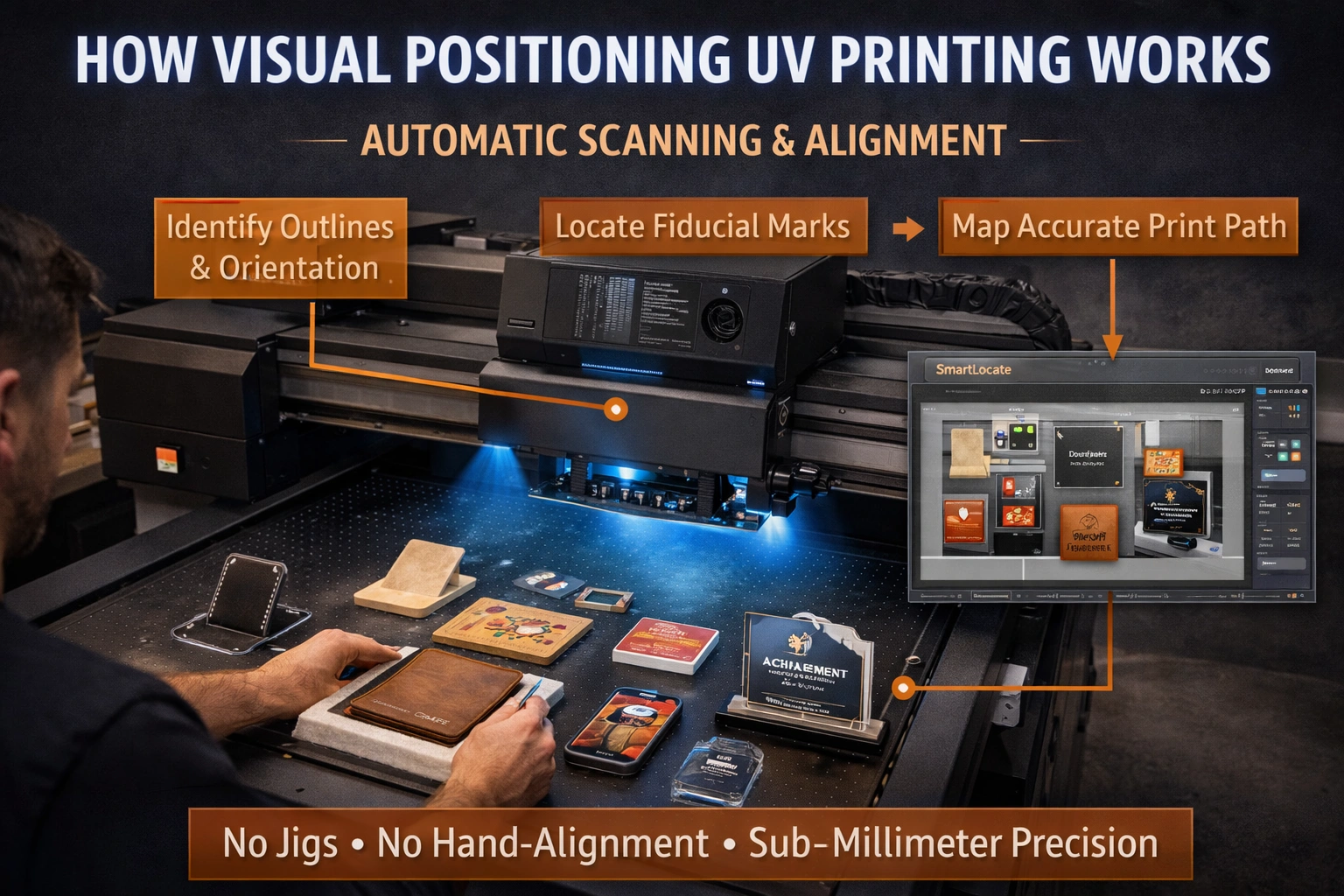

Understanding Visual Positioning Technology

Visual positioning UV printers use machine vision systems to automate alignment. Instead of relying on fixed physical references, the printer dynamically maps the position of each object on the bed.

Key Components

High-Precision CMOS Camera

Captures a detailed image of the entire print bed.Recognition Software

Identifies object outlines, orientation, and fiducial marks.Dynamic Print Mapping

Adjusts print paths in real time to match detected positions.Sub-Millimeter Accuracy

Ensures perfect registration even on complex shapes.

Implementation: Step-by-Step Workflow

1. Batch Preparation and File Setup

Designers prepare artwork in RIP software as usual. For mixed batches, all graphics are nested into a single 90×60 cm file.

For applications requiring extreme accuracy, such as name printing on awards, fiducial crosshair marks are included in the design or already exist on the substrate.

2. Load-and-Go Substrate Placement

Instead of building jigs, the operator:

Cleans the printer bed

Places various substrates loosely within the print area

Activates the vacuum bed

Perfect alignment is not required.

3. Automatic Scan and Recognition

With one command, the printer initiates its Scan & Align routine.

The camera system scans the entire bed and the software instantly detects:

Object shapes and contours

Rotation and position

Fiducial mark locations

Each design element is mapped precisely to its corresponding item.

4. Precision Printing and UV Curing

The print heads follow the dynamically generated path, depositing CMYK + White ink with exceptional accuracy.

Integrated UV-LED lamps cure the ink instantly, resulting in:

Scratch-resistant surfaces

No smudging

Immediate handling readiness

White ink enables vibrant printing on dark or textured materials like leather and stained wood.

5. Immediate Turnaround

Once printing finishes, items are ready for packaging immediately. No drying racks, no waiting time, and no risk of damage.

Measurable Business Results

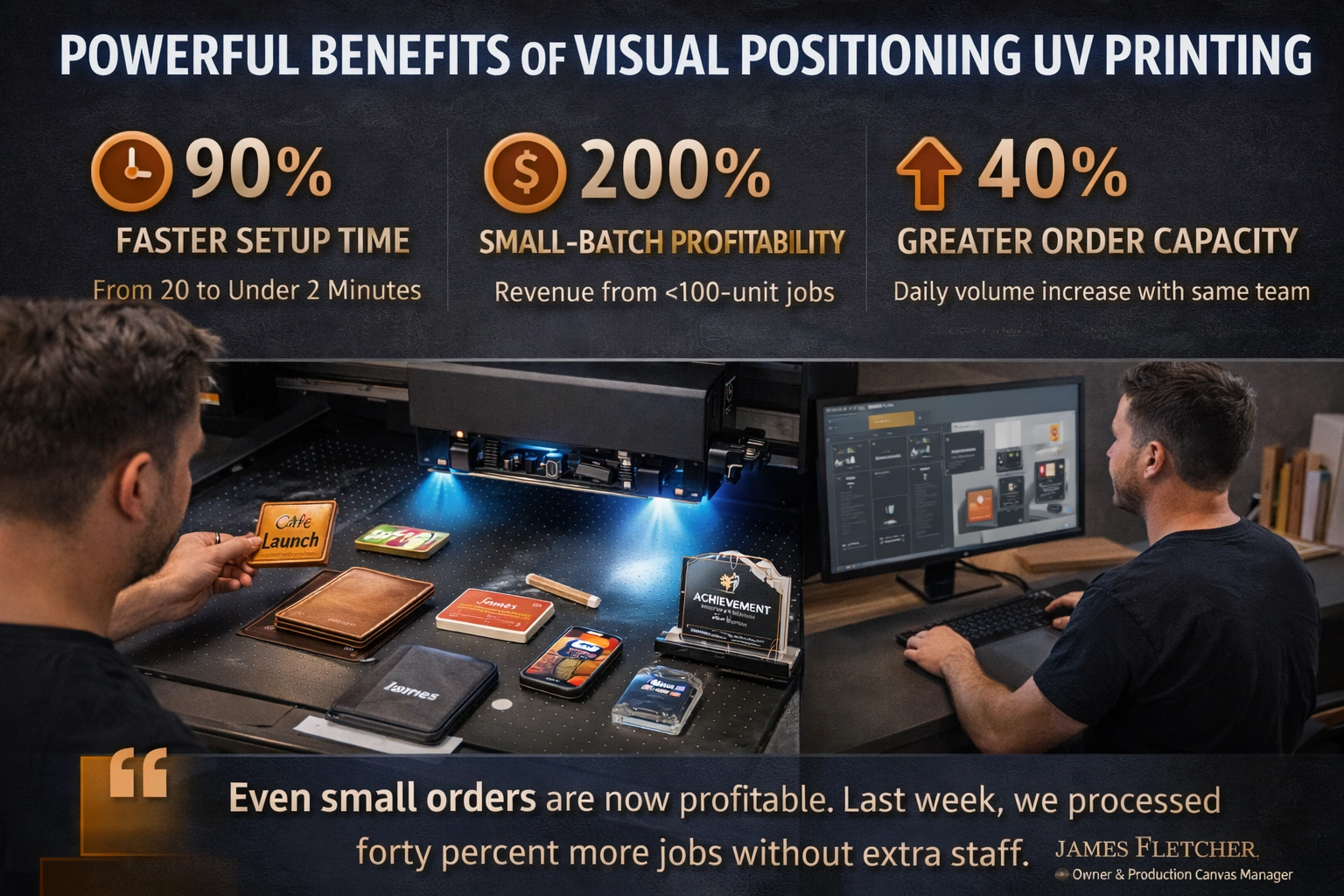

Drastic Reduction in Setup Time

Setup time reduced from 20 minutes to under 2 minutes

Test prints eliminated

Material waste reduced by over 80%

Profitability of Small Batches

Orders previously considered unviable became profitable. As a result:

Revenue from orders under 100 units increased by 200% in six months

Prototype and sample orders became routine work

New Revenue Streams Unlocked

The studio launched an Award Personalization Service, printing names and dates onto pre-engraved plaques and trophies with 100% accuracy.

What was once too risky became a high-margin offering.

Increased Operational Capacity

By running true mixed batches:

Machine uptime increased significantly

Daily order processing rose by 40%

No additional staff or overtime required

Competitive Advantage Through Automation

Visual positioning transformed Urban Canvas Prints from a setup-heavy workshop into a highly automated production environment.

Key advantages include:

Faster turnaround times

Higher consistency

Reduced operator dependency

Greater creative freedom

Rather than competing on price alone, the studio now competes on capability and reliability.

Client Testimonial

“The MTuTech visual system UV printer 9060 transformed our workshop from a bottleneck of manual setup to a seamless flow of automated production. The 90×60 cm size is the sweet spot—large enough for multiple items, yet compact and efficient for our daily promo product mix.

We now confidently accept jobs we used to refuse. The visual positioning isn't just a feature; it's our new business model. Last week, we printed 15 different sample products for a marketing agency in one unattended cycle—something utterly impossible before. It’s our ultimate competitive advantage.”

— James Fletcher, Owner & Production Manager, Urban Canvas Prints

Why Visual Positioning Is the Future of Promotional Printing

As demand for customization continues to rise, print businesses must move beyond manual processes. Visual positioning UV printing represents a fundamental shift:

From static to intelligent production

From manual alignment to automated precision

From risk avoidance to opportunity creation

Studios that adopt this technology position themselves for long-term growth in a market that increasingly values speed, accuracy, and personalization.

Conclusion

The experience of Urban Canvas Prints demonstrates that visual positioning UV printing is not just a technological upgrade—it is a strategic transformation. By eliminating setup inefficiencies, reducing waste, and unlocking new revenue streams, the MTuTech Visual Positioning UV Printer 9060 enabled the studio to scale profitably without increasing overhead.

For modern print businesses operating in competitive promotional markets, visual positioning is no longer optional. It is the foundation of a smarter, faster, and more resilient production model.

For those interested in enhancing their UV printing capabilities, explore our high-quality Visual Positioning UV printers here.