Implementing Machine Learning for Visual UV Print Correction

Introduction

In the world of digital printing, precision and quality are paramount. Visual UV printing, known for its vibrant colors and rich textures, demands high accuracy to meet the expectations of both businesses and consumers. However, achieving flawless prints can often be fraught with challenges. That’s where machine learning comes into play. By implementing machine learning algorithms, businesses can enhance their visual UV print correction processes, ensuring exceptional quality while reducing waste and increasing efficiency.

Understanding Visual UV Printing

Visual UV printing uses ultraviolet light to cure or dry the ink as it is printed on various surfaces. This method provides a range of benefits, including:

·

Vibrant Colors: UV printing allows for bold colors and intricate details that can bring designs to life.

·

·

Versatile Substrates: It can be applied to a variety of materials, including plastic, glass, metal, and paper.

·

·

Speed: The curing process is immediate, allowing for faster production times.

·

Despite these advantages, imperfections in print quality can occur due to several factors, including misalignment, variations in ink thickness, and substrate irregularities. The implementation of machine learning can significantly improve the correction of these visual imperfections.

The Role of Machine Learning in Print Correction

Machine learning, a branch of artificial intelligence, focuses on creating algorithms that can learn from and make predictions based on data. In the context of visual UV print correction, machine learning can be utilized to analyze printing processes and detect deviations from the desired output. Here’s how it works:

Data Collection

The first step in implementing machine learning is collecting data from previous print jobs. This data may include:

·

Color measurements

·

·

Print quality assessments

·

·

Feedback from operators and technicians

·

This data serves as the foundation for building the machine learning model, enabling it to learn patterns and discrepancies in print quality.

Model Training

Once data has been gathered, it can be used to train machine learning models. Using algorithms such as regression, decision trees, or neural networks, the system learns from historical data to identify the factors that contribute to print defects. During this phase, the model becomes more proficient in predicting potential print quality issues.

Real-Time Analysis and Correction

With a trained model in place, real-time analysis can be conducted during the printing process. As the visual UV printer operates, the machine learning system monitors various parameters, such as:

·

Ink viscosity

·

·

Print speed

·

·

Substrate feed

·

When abnormalities are detected, the system can alert operators or even make automatic adjustments, thus ensuring that print quality is maintained throughout the production run.

Benefits of Implementing Machine Learning

The integration of machine learning into visual UV print correction provides several benefits:

Enhanced Print Quality

By identifying and correcting issues in real time, machine learning contributes to the production of higher-quality prints. This consistency helps companies maintain their reputations and meet customer expectations.

Reduced Waste and Cost

Machine learning can significantly reduce material waste by catching errors before they result in finished product flaws. This, in turn, lowers production costs, making businesses more competitive.

Efficiency in Production

Automated corrections and adjustments allow for smoother operations, reducing downtime associated with manual quality checks. This increased efficiency can lead to shorter turnaround times for clients.

Informed Decision-Making

The data analysis capabilities of machine learning provide valuable insights into production processes. This information can aid in strategic planning and decision-making, enabling businesses to allocate resources more effectively.

Key Features of Machine Learning Systems in UV Printing

When considering the implementation of machine learning for visual UV print correction, it helps to know which features to look for:

Predictive Analytics

Machine learning systems can offer predictive analytics tools that forecast potential issues based on historical data, helping operators proactively address concerns before they impact print quality.

Automated Calibration

Advanced machine learning algorithms can automatically calibrate printers based on current production conditions, ensuring that them settings are always optimized for the best results.

Custom Reporting

Robust reporting features enable companies to analyze trends and performance metrics. This information not only helps in troubleshooting existing issues but also in forecasting future production capabilities.

Steps to Implement Machine Learning in Your Printing Facility

If your business is considering integrating machine learning into its visual UV print processes, here are the key steps to follow:

1. Assess Your Current Processes

Evaluate your existing print workflows and identify areas where quality issues frequently arise. Consider the types of data you have available for analysis.

2. Choose the Right Technology Partner

Select a technology partner with experience in machine learning applications within the printing industry. This partner can guide you through the implementation process.

3. Develop a Data Strategy

Establish a plan for data collection and management. Ensure that data is clean, relevant, and comprehensive enough to train your machine learning models effectively.

4. Engage in Pilot Testing

Before a full-scale rollout, conduct pilot tests to fine-tune your system. Collect feedback from operators to ensure the system meets operational needs.

5. Train Your Team

Ensure that your team is well-trained on the new system. Understanding how to interact with the machine learning tools will maximize their benefits and efficiency.

6. Monitor and Optimize

Post-implementation, continue to monitor system performance. Use the insights gained to make iterative improvements to your processes and machine learning models.

Conclusion

The implementation of machine learning for visual UV print correction represents a pivotal step in optimizing print quality and operational efficiency. By harnessing technology, businesses can proactively address challenges, reduce waste, and significantly enhance their product offerings. A commitment to ongoing learning and adaptation will ensure that your printing processes remain competitive and capable of meeting the demands of an ever-evolving market.

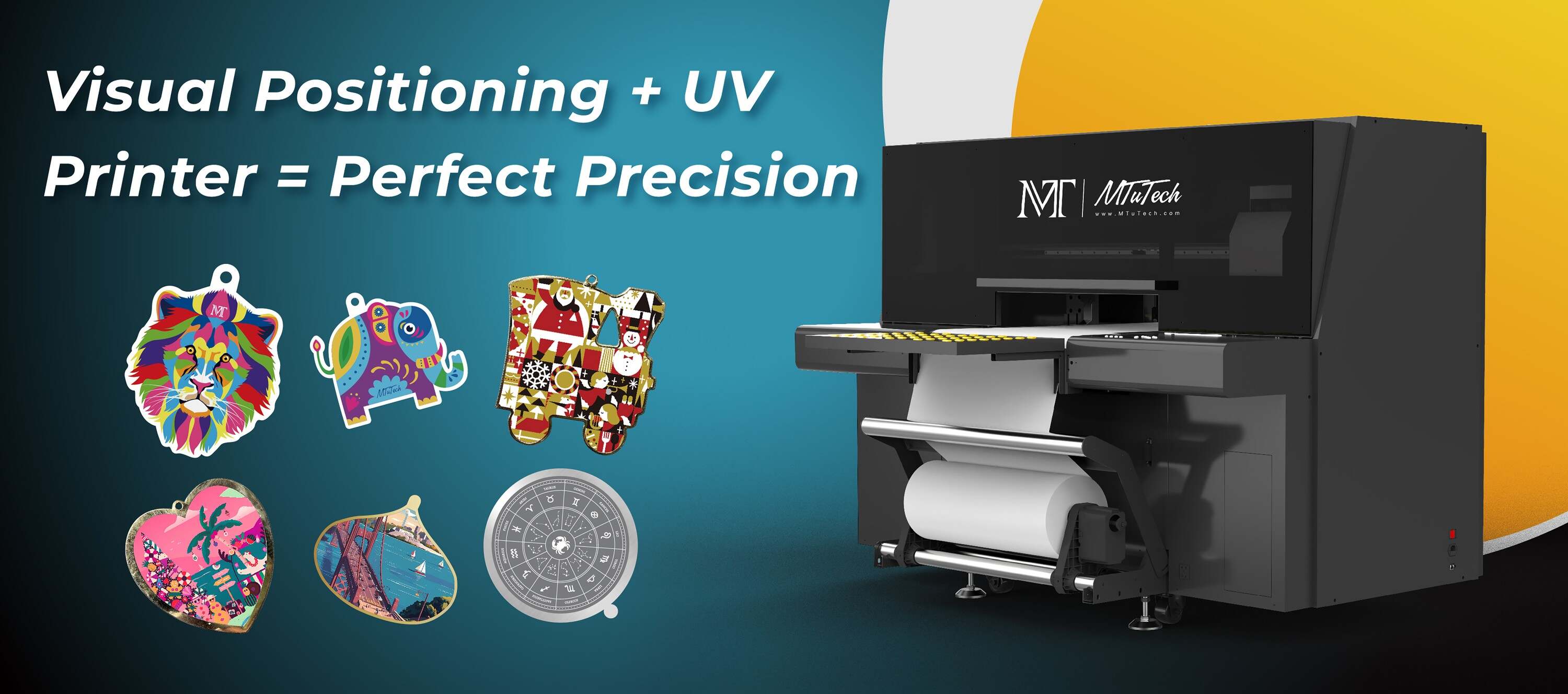

For manufacturers looking for high-quality equipment that integrates seamlessly with advanced correction systems, explore our high-quality Visual Positioning UV printers here.

FAQ

What is visual UV printing?

Visual UV printing is a method that uses ultraviolet light to cure or dry the ink as it is printed, allowing for vibrant colors and the ability to print on various materials.

What are the benefits of using machine learning in printing?

Machine learning enhances print quality, reduces waste, increases production efficiency, and provides valuable insights for informed decision-making.

How does machine learning contribute to quality assurance in printing?

Machine learning analyzes production data in real time, identifying deviations from quality standards and allowing for immediate corrections to be made.

What initial steps should be taken before implementing machine learning?

Assess your current processes, choose the right technology partner, develop a data strategy, and engage in pilot testing to ensure a successful implementation.

How can machine learning reduce costs in printing?

By minimizing material waste and improving production efficiency, machine learning helps lower operational costs and enhances overall profitability.