Integrating Visual UV Printers in Smart Manufacturing Lines

Introduction

In the ever-evolving landscape of manufacturing, the integration of advanced technologies is crucial for optimizing production efficiency and enhancing product quality. One such innovation that is gaining traction in smart manufacturing is the use of Visual UV printers. These printers not only provide superior print quality but also seamlessly integrate with automated manufacturing processes. In this blog post, we will explore the benefits, features, and strategies for incorporating Visual UV printers into smart manufacturing lines.

What is a Visual UV Printer?

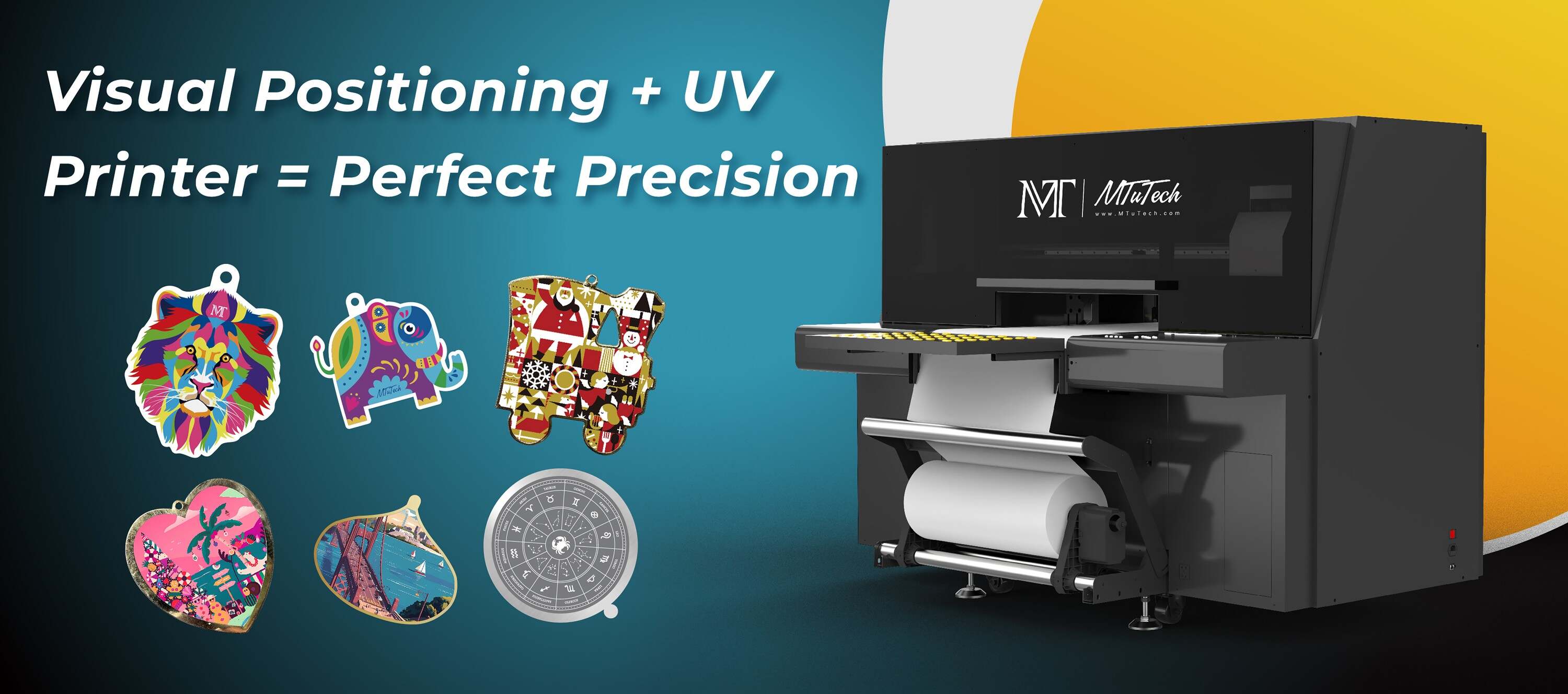

A Visual UV printer is a specialized digital printing technology that utilizes ultraviolet (UV) light to cure or dry ink as it is printed. This process allows for high-quality, durable prints on various substrates, including plastics, wood, metal, and glass. The "visual positioning" aspect refers to the printer's ability to precisely align graphics and images, ensuring exceptional quality and accuracy in print outputs.

Benefits of Integrating Visual UV Printers

1. Enhanced Print Quality

Visual UV printers offer unparalleled print resolution and color vibrancy. The curing process ensures that colors remain vibrant and true to the original design, providing a polished finish that is essential for high-end products.

2. Versatility in Substrates

One of the standout features of Visual UV printers is their ability to print on a wide array of materials. Manufacturers can produce items ranging from promotional products to packaging and signage without the need for extensive setup changes.

3. Reduced Production Time

The instant curing capability of UV printing drastically reduces the time required for drying. This means that products can move through the production line faster, leading to improved overall throughput and productivity.

4. Eco-Friendly Operations

Unlike traditional printing methods that use solvent-based inks and require long drying times, UV inks are more environmentally friendly. They emit fewer volatile organic compounds (VOCs) and reduce waste, contributing to sustainable manufacturing practices.

5. Cost-Effectiveness

By minimizing waste, reducing labor associated with drying time, and enhancing speed, Visual UV printers can lead to significant cost savings. Over time, the investment in this technology pays for itself through increased production efficiency and lower operational costs.

Features of Visual UV Printers

1. High-Resolution Printing

Modern Visual UV printers are capable of delivering prints at resolutions that can exceed 1200 dpi. This ensures that even the most intricate designs maintain accuracy and clarity, essential for branding and presentation.

2. Advanced Color Management

With built-in advanced color management systems, these printers allow for precise color matching. This feature is particularly beneficial for companies that require consistency across multiple production runs or various product lines.

3. Automatic Material Recognition

Visual UV printers are equipped with sensors that can automatically detect the type and thickness of the material being printed. This capability simplifies setup and reduces the chances of errors, which can cost time and resources.

4. User-Friendly Interfaces

The latest models come with intuitive touch-screen interfaces that simplify operation and workflow management. Operators can easily adjust settings, monitor print progress, and troubleshoot issues without extensive technical training.

5. Connectivity and Automation Compatibility

Integration capabilities with other smart manufacturing systems allow Visual UV printers to communicate with product management software, enabling automated inventory tracking and workflow optimization.

Successfully Integrating Visual UV Printers

Integrating Visual UV printers into your smart manufacturing line requires careful planning and consideration. Here are some strategies to ensure a successful implementation:

1. Assess Your Manufacturing Needs

Before investing in a Visual UV printer, evaluate your current production processes, product requirements, and any specific challenges you face. This assessment will guide you in selecting the right printer model and features.

2. Train Your Workforce

Proper training of operations staff is essential to maximize the benefits of new technology. Ensure your team is well-versed in operating and maintaining the Visual UV printer to minimize downtime and errors.

3. Integrate with Existing Systems

Make sure the Visual UV printer can easily integrate with your existing manufacturing systems, such as inventory management or product design software. This will streamline workflows and enhance overall efficiency.

4. Monitor and Optimize

Once the printer is integrated, continuously monitor its performance. Gather data on production output, quality, and workflow efficiency to identify areas for improvement. Regular optimization can lead to ongoing gains in productivity and cost savings.

Case Studies: Visual UV Printers in Action

1. Automotive Industry

In an automotive manufacturing plant, a Visual UV printer was integrated into the production line to produce dashboard decals. The quick-drying capability allowed for immediate assembly, reducing lead times by 30% while ensuring high-quality, durable printing.

2. Packaging Sector

A packaging company that integrated a Visual UV printer reported a significant reduction in material waste due to its precise printing capabilities. This not only enhanced their sustainability goals but also improved their profit margins by 15%.

Challenges and Solutions

1. Initial Investment Costs

While the initial cost of Visual UV printers may be high, consider the long-term savings and efficiency gains they provide. Financing options or leasing arrangements can make adoption more accessible.

2. Maintenance and Technical Issues

Regular maintenance is crucial for keeping the printers running efficiently. Establish a comprehensive maintenance schedule and train personnel to handle minor repairs and troubleshooting to minimize potential disruptions.

3. Transitioning Existing Workflows

Transitioning to a new technology can disrupt existing workflows. Conduct pilot tests to smooth the transition, allowing your team to adapt gradually while assessing integration impacts.

Conclusion

Integrating Visual UV printers into smart manufacturing lines represents a powerful opportunity for manufacturers to enhance their production capabilities. With the ability to deliver high-quality prints on diverse materials, reduce production times, and improve cost efficiency, these printers are revolutionizing the industry. By carefully considering workflow integration, staff training, and ongoing optimization, businesses can fully leverage the benefits of this technology.

For companies looking to adopt this innovative printing solution, explore our high-quality Visual Positioning UV printers here to take your manufacturing processes to the next level.

FAQ

What types of materials can be printed on with a Visual UV printer?

Visual UV printers can print on various substrates, including plastics, metal, wood, glass, and more. This versatility allows manufacturers to explore numerous product opportunities.

How do Visual UV printers affect production speed?

Visual UV printers significantly enhance production speed due to their instant drying capability, allowing printed items to be handled and processed immediately without waiting for traditional drying methods.

Are Visual UV printers environmentally friendly?

Yes, Visual UV printers are considered more environmentally friendly compared to traditional printing methods. They typically emit fewer VOCs and reduce waste due to their efficient ink usage and fast curing processes.

What is the lifespan of prints produced by Visual UV printers?

Prints produced by Visual UV printers are known for their durability and resistance to fading, cracking, and moisture. This longevity makes them ideal for both indoor and outdoor applications.

Can Visual UV printers be integrated into existing production lines easily?

Yes, Visual UV printers are designed for seamless integration into existing production lines, especially in smart manufacturing environments. They are compatible with various automation and management systems, simplifying the integration process.