Troubleshooting Shadowing Issues in Visual UV Printing

Introduction

Visual UV printing has transformed the way businesses approach printing, providing vivid colors and stunning details on various substrates. However, even the most advanced UV printers can experience shadowing issues, which can affect the quality of the final output and customer satisfaction. This blog post aims to delve into the common causes of shadowing in visual UV printing, how to troubleshoot these issues, and best practices to avoid them in the future.

Understanding Shadowing Issues

Before diving into troubleshooting, it's crucial to understand what shadowing is in the context of UV printing. Shadowing refers to the unwanted dark areas or outlines that appear in printed images, often manifesting as inconsistencies in color density and detail.

Common Causes of Shadowing

Shadowing can occur for several reasons during the printing process. Some common causes include:

·

Inadequate curing: If the UV light is not properly curing the ink, it can lead to shadowing.

·

·

Substrate issues: Different substrates react differently to UV inks; some may absorb excess ink or not adhere properly.

·

·

Printer settings: Incorrect printer settings, such as ink density and print speed, can contribute to shadowing.

·

·

Print head misalignment: A misaligned print head can cause uneven ink distribution, leading to shadowing.

·

·

Environmental factors: Humidity and temperature can affect ink performance and curing.

·

Troubleshooting Shadowing Issues

Now that we understand the common causes of shadowing, let's look at how to troubleshoot these issues effectively.

1. Check the Curing Process

Ensure that the UV curing system is functioning optimally. If the ink is not curing properly:

·

Verify lamp intensity and positioning.

·

·

Inspect for worn-out bulbs that may need replacement.

·

·

Adjust the curing speed based on the substrate type.

·

2. Assess Substrate Selection

The choice of substrate can have a significant impact on print quality. Here’s what you can do:

·

Test different substrates to determine which ones work best with your inks.

·

·

Ensure substrates are free from dust, oils, or contaminants that may interfere with adherence.

·

3. Review Printer Settings

Printer settings play a crucial role in preventing shadowing. Follow these guidelines:

·

Adjust ink density settings; too much ink can lead to pooling, resulting in shadowing.

·

·

Experiment with print speed. Slower speeds can provide more uniform ink application, minimizing shadowing.

·

·

Consider the use of multiple passes for high-resolution images.

·

4. Realign the Print Head

A misaligned print head can result in uneven ink distribution. To align the print head:

·

Run a print head alignment test through your printer’s maintenance menu.

·

·

Follow the manufacturer’s instructions for realignment.

·

5. Control Environmental Conditions

Environmental factors can greatly influence printing outcomes. To maintain optimal conditions:

·

Keep your printing area at a consistent temperature (ideally between 20°C to 25°C).

·

·

Monitor humidity levels as high humidity can affect ink curing.

·

Advanced Techniques to Minimize Shadowing

Once basic troubleshooting has been implemented, consider adopting advanced techniques to further reduce shadowing effects.

1. Color Management

Proper color management ensures that colors are consistent across prints, minimizing the likelihood of shadowing. Implement these practices:

·

Use calibrated monitors and printers to ensure true color representation.

·

·

Utilize ICC profiles tailored for your specific inks and substrates.

·

2. Regular Maintenance

Routine maintenance of your UV printer is essential. Key maintenance practices include:

·

Frequent cleaning of the print heads and curing system.

·

·

Regularly checking and replacing worn components, such as rollers and belts.

·

3. Continuous Training for Operators

Ensuring that operators are well trained can significantly enhance the quality of prints. Invest in:

·

Regular workshops and training sessions on advanced printing techniques.

·

·

Updated materials on the latest printing technology and troubleshooting methods.

·

Case Studies: Real-world Applications

To better understand shadowing in visual UV printing, let’s look at a couple of case studies.

Case Study 1: A Signage Company

A signage company was experiencing shadowing in their prints due to a mismatch in ink and substrate. With proper testing, they determined that using an alternative substrate greatly improved print quality and eliminated shadowing.

Case Study 2: Commercial Printer

A commercial printer was facing issues with uneven prints. After implementing regular maintenance routines and printer calibration, they observed a significant decrease in shadowing and an overall improvement in print consistency.

Conclusion

Shadowing issues in visual UV printing can be frustrating, but with a systematic approach to troubleshooting, they can be resolved effectively. By understanding common causes, implementing best practices, and conducting regular maintenance, printers can significantly enhance the quality of their prints. Continuous training for operators and strategic substrate selection are also critical components in minimizing shadowing issues.

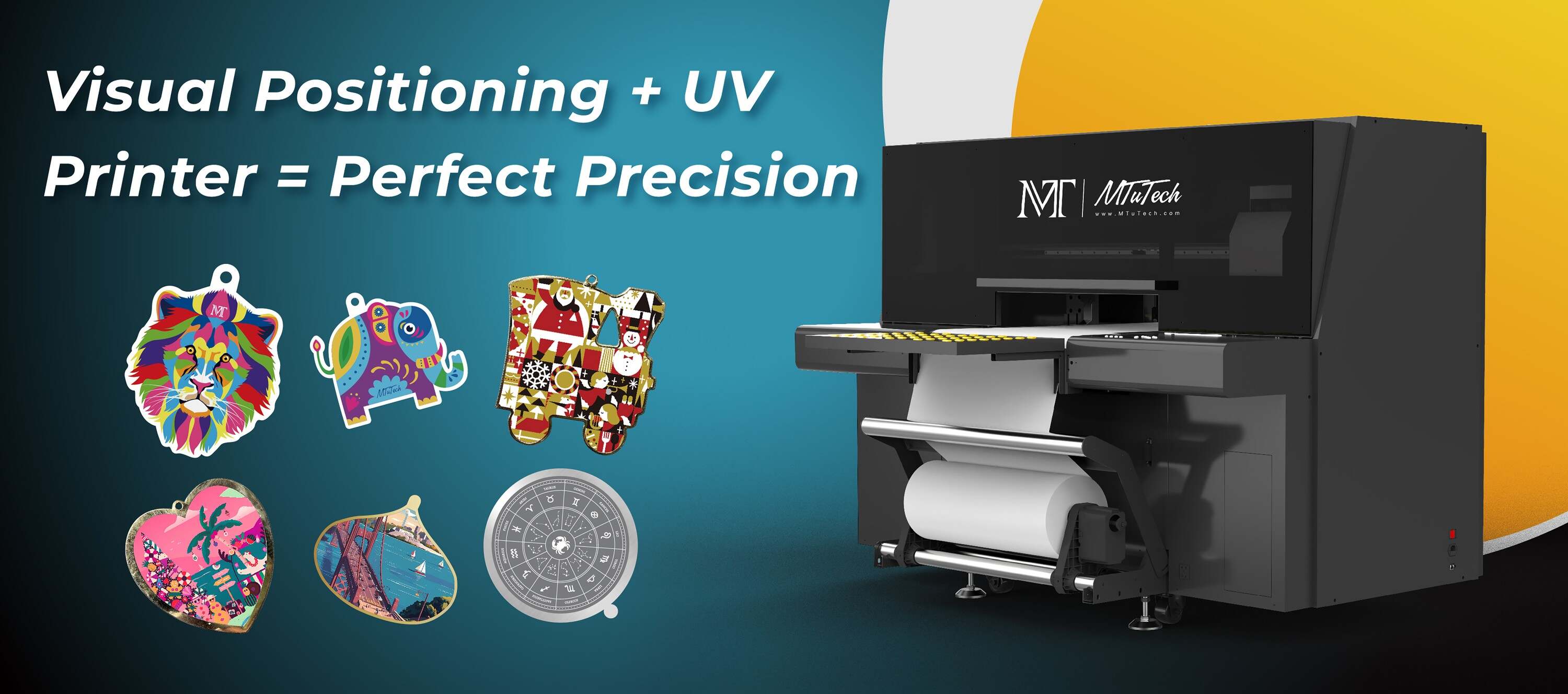

If you're looking to enhance your printing capabilities and tackle shadowing problems head-on, browse through the options available to you by visiting explore our high-quality Visual Positioning UV printers here.

FAQ

What is shadowing in visual UV printing?

Shadowing refers to unwanted dark areas or outlines that appear in printed images, affecting the print's overall quality and consistency.

What are the common causes of shadowing?

Common causes include inadequate curing, substrate issues, incorrect printer settings, print head misalignment, and environmental factors like humidity and temperature.

How can I troubleshoot shadowing issues?

To troubleshoot shadowing, check the curing process, assess substrate selection, review printer settings, realign the print head, and control environmental conditions.

What advanced techniques can minimize shadowing?

Advanced techniques include employing proper color management, conducting regular maintenance on the printer, and continuous training for operators to keep them updated on best practices.