Understanding the Latency Factor in Visual Positioning UV Printing

Introduction

In the world of printing technologies, visual positioning UV printing has emerged as a transformative solution for various industries. Known for its precision and versatility, this printing technique significantly enhances the printing quality and efficiency of numerous applications, from signage to decorative graphics. However, one critical aspect often overlooked in these discussions is the latency factor. Understanding latency can help businesses optimize their operations and improve product quality. In this blog post, we will delve into the latency factor in visual positioning UV printing, its implications, and how to manage it effectively.

What is Visual Positioning UV Printing?

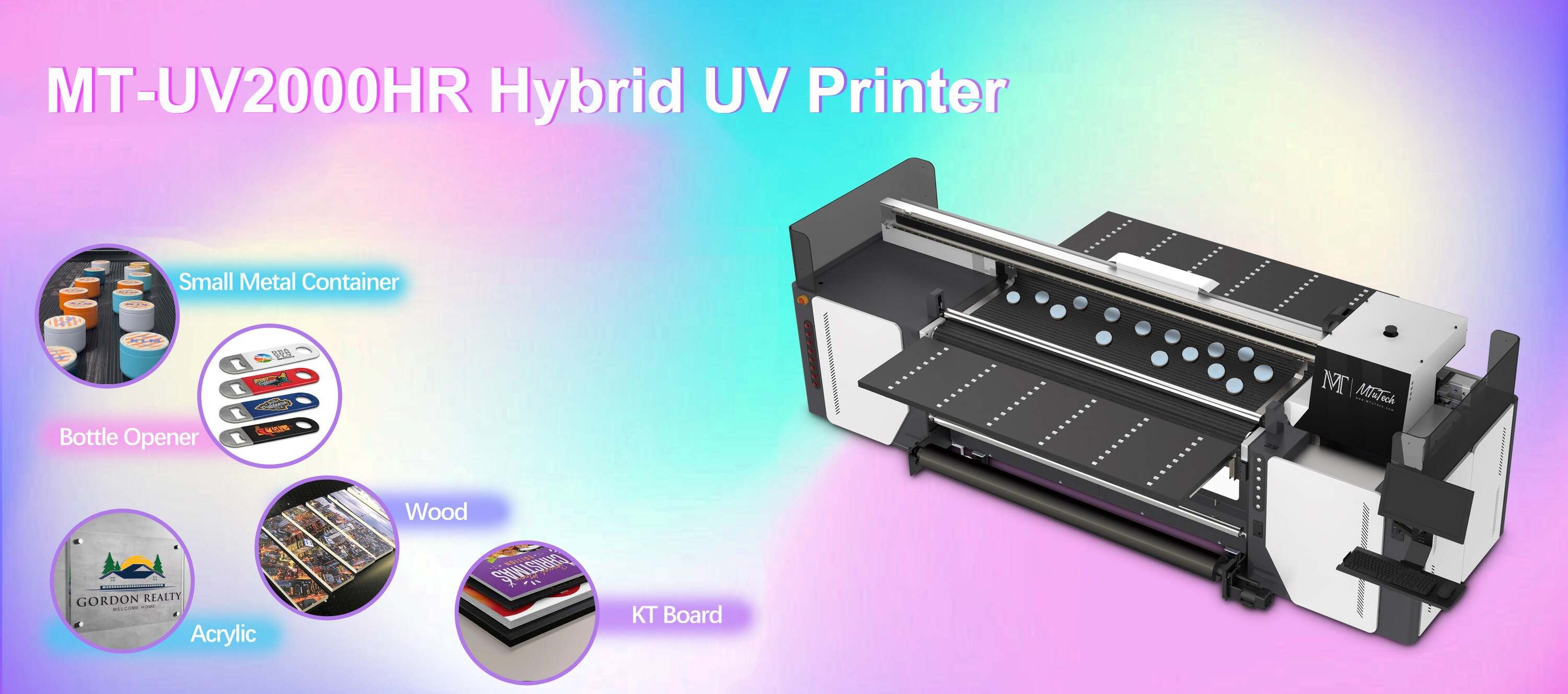

Visual positioning UV printing employs advanced technology that uses ultraviolet light to cure ink as it is printed onto surfaces. This technology allows for high-definition graphics, vibrant colors, and the ability to print on various substrates, including wood, metal, plastic, and glass.

How Does it Work?

The process involves several stages:

·

Ink Preparation: UV printing uses special inks that are sensitive to UV light, allowing them to dry quickly upon exposure.

·

·

Printing: The printer uses precision nozzles to lay down the ink while the substrate moves through the system.

·

·

UV Curing: As soon as the ink is laid on the substrate, UV lamps cure the ink almost instantly, resulting in a robust, lasting print.

·

Understanding Latency in UV Printing

Latency in this context refers to the delay experienced between the initiation of the printing process and the execution of the output. The factors that contribute to latency can encompass hardware limitations, software processing time, and the workflow's complexity. High latency can affect print quality, cause errors, and lead to inefficient production.

Key Factors Contributing to Latency

·

Technology Capabilities: The specifications of the printer play a significant role. Printers with advanced technology tend to have lower latency.

·

·

Software Efficiency: The software used to operate the printer must efficiently process data and communicate with the hardware.

·

·

Material Characteristics: The type and thickness of the substrate can influence latency; some materials require more curing time.

·

·

Operator Expertise: The skill and experience of the operator can also affect how quickly jobs are prepared and executed.

·

Implications of Latency on Print Quality

The latency factor can have multiple implications on the final product. Here are a few ways latency can compromise print quality:

Print Resolution

When latency is high, there may be inconsistencies in the fluidity of the printing process, leading to lower print resolution. This can result in patches of uneven details and colors.

Color Accuracy

Longer processing times may lead to misalignment of colors, particularly in multi-layer prints where precise layering is crucial.

Overall Efficiency

High latency can result in longer turnaround times, affecting the efficiency of the printing operation. This can lead to missed deadlines and decreased customer satisfaction.

Managing Latency in Visual Positioning UV Printing

To optimize operations in visual positioning UV printing, here are some strategies to manage latency effectively:

Upgrading Technology

Investing in modern, high-quality UV printers can significantly reduce latency. Technologies continue to evolve, and newer printers tend to have better speed and efficiency.

Optimizing Software

Choosing the right printing software is essential. Look for programs that can handle large files proficiently and provide seamless communication between the design and printing phases.

Regular Maintenance

Regularly maintaining and calibrating printers can prevent delays caused by hardware malfunctions. Proper routines can ensure that the printer operates efficiently and accurately.

Training Personnel

Investing in training for your staff can enhance their proficiency in using the technology and workflow management. Well-trained operators can swiftly troubleshoot issues and optimize processes to reduce latency.

Future Trends in Visual Positioning UV Printing

The world of UV printing is not static; it is continually evolving. As we look to the future, we can anticipate several trends that may reshape visual positioning UV printing:

Increased Automation

Automation in UV printing processes is expected to continue gaining traction. Automated systems may help reduce human error while optimizing workflow processes, thus minimizing latency.

Enhanced Software Features

Software developers are likely to advance tools that integrate better with UV printers, offering features that improve job efficiency and ease of use.

Sustainable Practices

As eco-consciousness grows, UV printing technologies will probably incorporate more sustainable inks and substrates, lessening the latency associated with curing and drying times without sacrificing quality.

Conclusion

Understanding the latency factor in visual positioning UV printing is crucial for businesses seeking to enhance their productivity and print quality. By identifying components that contribute to latency and implementing effective strategies for management, companies can streamline their operations and deliver exceptional products.

For businesses looking for high-quality visual positioning UV printers, Explore our high-quality Visual Positioning UV printers here. Investing in the right technology is foundational for success in the competitive printing industry.

FAQ

What is latency in the context of UV printing?

Latency refers to the delay between initiating the printing process and the actual output. In UV printing, it can affect the quality and efficiency of the final print.

How can I reduce latency in my UV printing processes?

You can reduce latency by upgrading technology, optimizing software, maintaining equipment, and training staff effectively.

What impact does printing speed have on print quality?

Increased printing speed can sometimes compromise print quality if latency is not managed. If the process can't keep up with the demand, mistakes may occur, affecting resolution and color accuracy.

Are there specific materials that cause more latency in UV printing?

Yes, thicker and more complex materials may require more curing time, contributing to overall latency. Choosing the right substrates is essential for efficient UV printing.

What are the benefits of modern UV printers compared to older models?

Modern UV printers typically offer faster speeds, improved print quality, and lower latency due to advancements in technology and software. These features allow for greater efficiency and flexibility in printing applications.