Using Visual Positioning for Precision Logo and Text Placement

Introduction

In today's competitive landscape, businesses are constantly seeking ways to enhance their branding and product visibility. One vital aspect of this is the placement of logos and text on products, packaging, and marketing materials. Traditional printing methods often struggle to deliver the precision required to maintain brand integrity and aesthetics. This is where the innovative technology of visual positioning comes into play.

Visual positioning utilizes advanced calibration and alignment techniques to ensure that logos and text are placed accurately on various surfaces. This blog will explore the benefits, features, and applications of visual positioning in enhancing logo and text placement, ensuring a flawless presentation every time.

Understanding Visual Positioning

Visual positioning technology integrates sophisticated imaging systems that allow printers to identify the exact placement of logos and text on products. By using sensors and cameras, this technology adjusts the positioning dynamically, ensuring that even when surfaces are uneven or irregular, the final output is spot-on.

Benefits of Visual Positioning

1. Accuracy and Precision

One of the most significant advantages of visual positioning technology is its unparalleled accuracy. The ability to detect the exact dimensions and alignment of surfaces means that logos and text can be placed with surgical precision. This is especially important for:

·

Custom promotional items

·

·

Industrial parts with strict branding guidelines

·

·

Packaging that requires fine details

·

2. Improved Efficiency

Visual positioning streamlines the printing process by minimizing the need for manual adjustments. This technology reduces setup time and allows for quick adjustments on the fly, leading to:

·

Faster production times

·

·

Less waste due to misalignments

·

·

Higher throughput rates in production environments

·

3. Enhanced Quality Control

The inherent error-checking capabilities of visual positioning systems significantly enhance quality control measures. These systems can identify discrepancies in placement in real time, allowing for immediate corrective actions, which results in:

·

Consistent quality across products

·

·

Lower rates of defective products

·

·

Increased customer satisfaction

·

4. Versatility Across Various Surfaces

Another benefit of using visual positioning technology is its adaptability to various surfaces, from flat to curved or textured. This means that businesses can expand their branding efforts across different mediums without worrying about alignment issues.

Features of Visual Positioning Technology

1. Integrated Imaging Systems

Visual positioning printers come equipped with high-resolution cameras that capture images of the substrate. These images are analyzed in real-time, enabling the printer to adjust its output based on the surface characteristics.

2. Automated Calibration

Incorporating automated calibration processes ensures that the printer can quickly adapt to changes in material or design without requiring extensive manual setup. This is particularly beneficial for production runs of varying lengths and complexities.

3. User-Friendly Interface

Modern visual positioning systems feature intuitive user interfaces that make it easier for operators to manage the printing process, set parameters, and troubleshoot issues as they arise. Training and onboarding new team members becomes an effortless task.

4. Data Tracking and Analytics

Advanced visual positioning printers often include data tracking capabilities that allow businesses to monitor printing performance over time. These insights can inform future production strategies, enabling continuous improvement.

Applications of Visual Positioning in Business

1. Promotional Products

Companies can leverage visual positioning for custom-branded items like mugs, t-shirts, and stationery. Precise logo placement ensures brand visibility and consistency, contributing to better marketing outcomes.

2. Packaging Solutions

In the highly competitive packaging domain, visual positioning helps brands maintain a polished look across all packaging designs, enhancing shelf appeal and brand recognition.

3. Industrial Applications

Manufacturers can utilize visual positioning for labeling industrial components, ensuring that company logos and compliance information are accurately placed on parts to meet regulatory standards.

4. Customized Items

Visual positioning enables the production of highly personalized items by ensuring precise text placement. Whether it’s a monogrammed gift or a unique corporate giveaway, this technology ensures every detail is perfect.

Choosing the Right Visual Positioning Printer

When selecting a visual positioning printer, consider several factors to ensure that you choose a model that fits your business needs:

·

Printer Resolution: Higher resolution allows for sharper, more detailed reproductions of logos and text.

·

·

Print Speed: If your production volume is high, look for a high-speed model to ensure efficiency.

·

·

Compatibility with Materials: Ensure that the printer can handle the materials you plan to use.

·

·

Support and Service: Prompt technical support and maintenance options are vital for minimizing downtime.

·

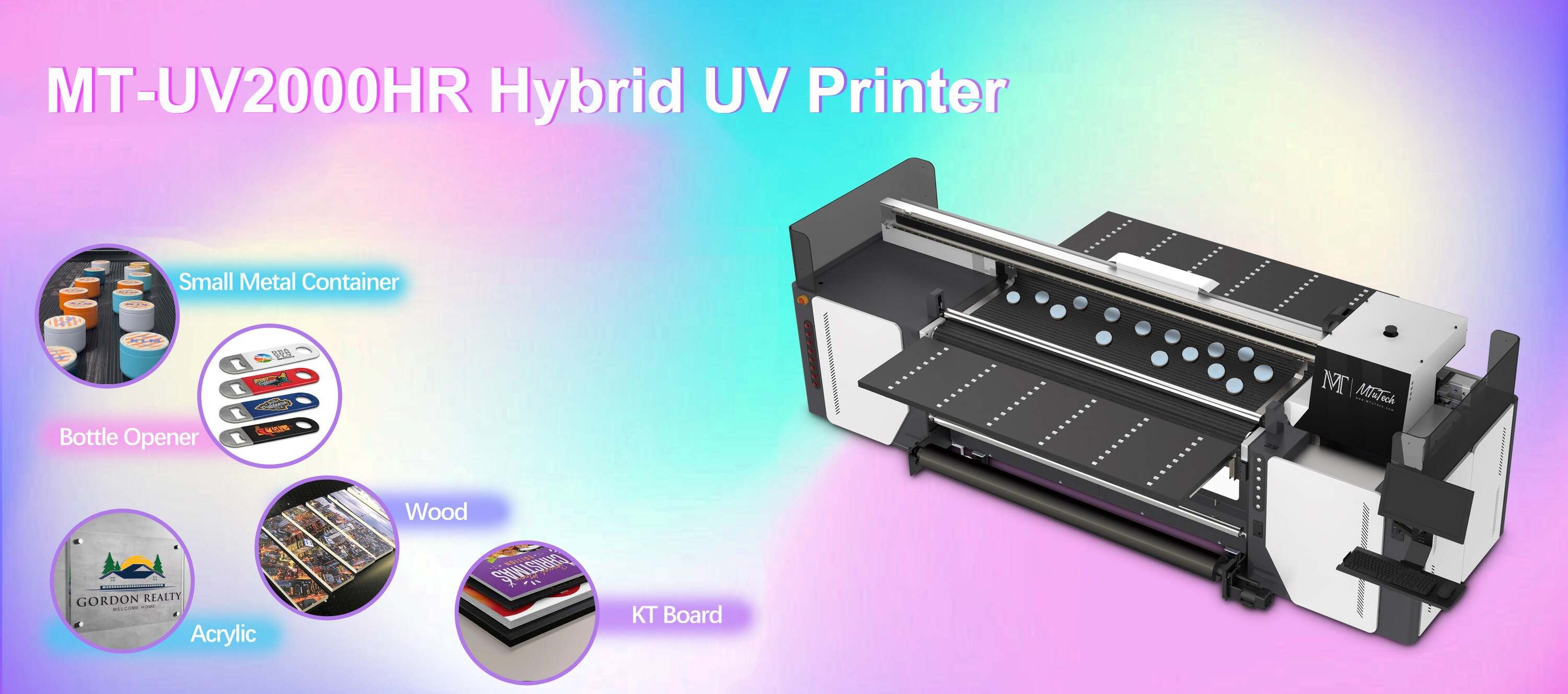

For a firsthand experience and to explore different options, explore our high-quality Visual Positioning UV printers here. Investing in advanced printing technology will have lasting effects on your business's branding strategy and overall production quality.

Conclusion

Visual positioning is revolutionizing how businesses approach branding and product presentation. Its ability to offer accurate, efficient, and versatile printing solutions makes it a game-changer across various industries. Whether you are customizing promotional products, ensuring compliance on industrial parts, or enhancing packaging aesthetics, incorporating visual positioning technology will undoubtedly elevate your brand presence.

FAQ

What is visual positioning technology?

Visual positioning technology is an innovative printing method that uses advanced imaging systems to accurately place logos and text on a variety of surfaces. It optimizes the printing process by ensuring precise alignment and calibration.

How does visual positioning improve printing efficiency?

By reducing setup time and the need for manual adjustments, visual positioning allows for quicker production rates while minimizing waste from misalignments, ultimately enhancing overall efficiency.

Can visual positioning technology be applied to any surface?

Yes, visual positioning technology is versatile and can adapt to both flat and irregular surfaces, making it suitable for a wide range of products and materials.

Is it easy to operate visual positioning printers?

Yes, modern visual positioning printers typically come with user-friendly interfaces, making them easy to operate even for those with minimal technical background.

What industries can benefit from visual positioning technology?

Nearly any industry that requires precise branding can benefit from visual positioning, including promotional products, packaging, and manufacturing applications.