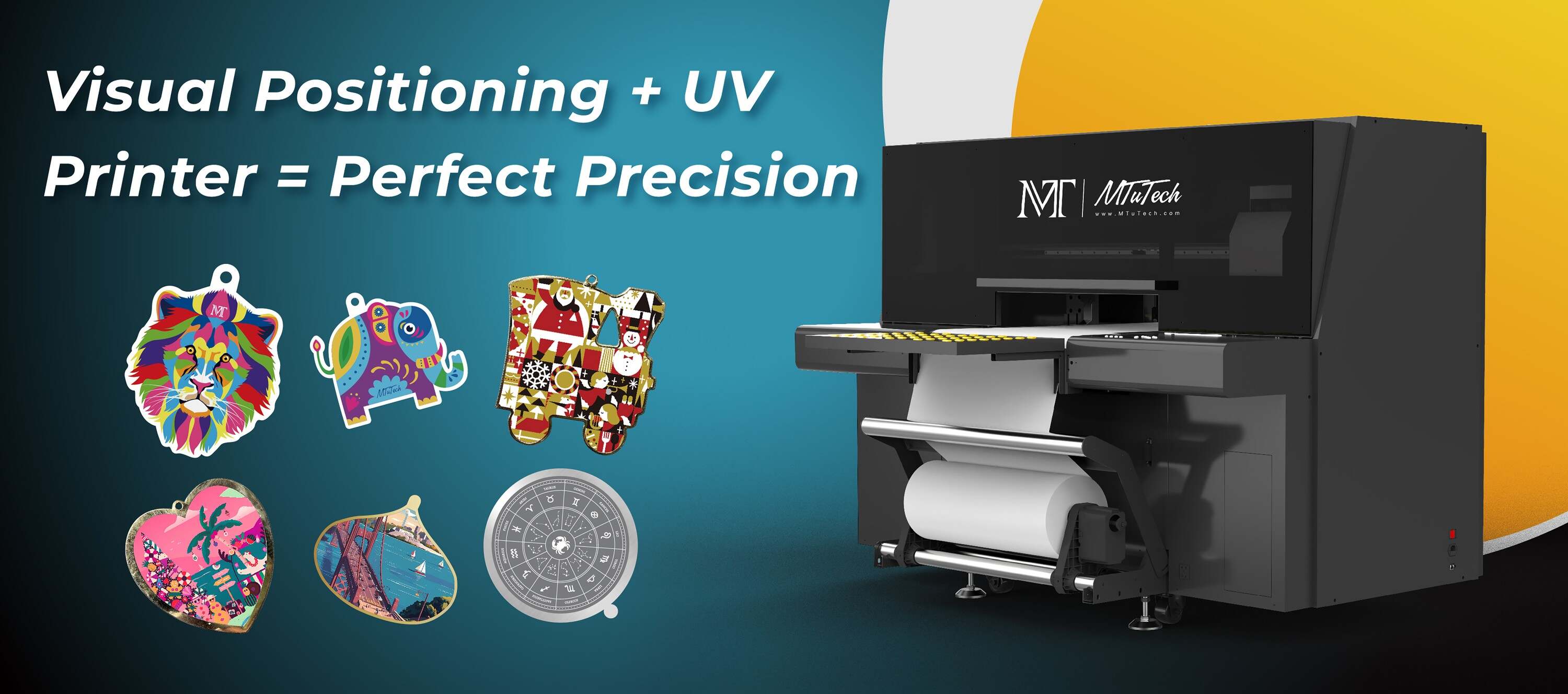

Visual Positioning Features to Look For Before You Buy a UV Printer

Introduction

Choosing a UV printer involves a thorough understanding of its features, particularly its visual positioning systems. These features play a crucial role in ensuring precision and efficiency in printing, especially for businesses that aim to deliver high-quality products consistently. In this blog post, we will explore essential visual positioning features to consider before making a purchase. By the end, you will be well-equipped to choose a UV printer that meets your needs.

What is a UV Printer?

A UV printer uses ultraviolet light to cure or dry the ink as it is printed. This technology allows for quick drying and high-quality images on a variety of surfaces. The incorporation of visual positioning features enhances the overall accuracy and usability of the device.

Importance of Visual Positioning Features

Visual positioning is integral to the functionality of a UV printer. It impacts both the quality of the final print and the efficiency of the printing process. Here are a few reasons why these features should be at the forefront of your decision-making:

·

Precision: Accurate placement of ink minimizes the risk of misalignments.

·

·

Efficiency: Streamlined processes reduce setup time and labor costs.

·

·

Quality Control: Enhanced visual feedback helps in maintaining print quality across different substrates.

·

Key Visual Positioning Features to Look For

When evaluating UV printers, consider the following visual positioning features that can significantly impact your printing experience:

1. Integrated Camera Systems

Many modern UV printers come with integrated camera systems that provide real-time monitoring of the print process. This feature enables:

·

Automatic Alignment: The camera can automatically adjust the print head or substrate based on visual feedback, ensuring perfect alignment.

·

·

Quality Assurance: Users can verify the print quality on-the-fly, instantly detecting misalignments or defects.

·

2. Optical Sensors

Optical sensors are vital for detecting the substrate’s edges and setting the correct print areas. Look for printers equipped with:

·

Edge Detection: Helps in avoiding misprints on the material.

·

·

Leveling Sensors: Ensures consistent print quality, especially when using uneven surfaces.

·

3. Print Head Positioning Technology

The print head positioning plays a crucial role in ensuring accurate prints. Consider printers that utilize:

·

Micro-stepping Technology: Provides better precision by allowing smaller incremental movements of the print head.

·

·

Dynamic Print Head Adjustment: This feature compensates for variations in substrate height, which is especially beneficial for printing on varied materials.

·

4. Calibration Algorithms

Calibration is essential for maintaining print accuracy over time. Look for printers that offer advanced calibration algorithms, which can:

·

Auto Calibration: Some printers can automatically calibrate after detecting a change in substrate or print conditions.

·

·

Custom Calibration Settings: Flexibility in customizing calibration settings can help achieve optimal results for different types of media.

·

5. User Interface and Software

A user-friendly interface makes a significant difference. Here are key software features to consider:

·

Visual Feedback Tools: These tools provide users with visual representations of their print jobs, allowing for quick assessments.

·

·

Remote Access Capabilities: Some advanced systems allow for remote monitoring and adjustments, which can be a game-changer for efficiency.

·

6. Multi-Substrate Support

UV printers that support various substrates often come with superior visual positioning features designed to work with those materials. Look for printers that can handle:

·

Flexible Materials: Such as vinyl and textiles, which require precise adjustments during printing.

·

·

Rigid Surfaces: Like wood and metal, which may need different positioning techniques.

·

Comparative Analysis of Visual Positioning Features

When evaluating different UV printers, it's helpful to compare their visual positioning capabilities side-by-side. Look for:

·

Performance metrics related to print accuracy and speed.

·

·

User reviews focusing on the efficiency of the visual positioning features.

·

·

The availability of technical support and software updates that improve visual positioning functionalities over time.

·

Conclusion

Investing in a UV printer is a significant decision for any business looking to enhance its printing capabilities. Understanding the importance of visual positioning features can help you choose a model that not only meets your current needs but also supports future growth. Take the time to evaluate cameras, sensors, and calibration technologies in your available options. After all, the right printer can elevate your products and streamline your operations.

Are you ready to enhance your printing process? Explore our high-quality Visual Positioning UV printers here and discover the difference they can make for your business.

FAQ

What are visual positioning features in UV printers?

Visual positioning features are technological elements that enhance the accuracy and efficiency of print jobs in UV printers. These may include integrated cameras, optical sensors, print head positioning technology, calibration algorithms, and user-friendly software interfaces.

Why are integrated camera systems important in UV printers?

Integrated camera systems allow for real-time monitoring and automatic adjustments for perfect alignment, improving print quality and reducing the likelihood of misprints.

How do optical sensors enhance print quality?

Optical sensors help detect the edges of the substrate, ensuring that prints are made within the designated areas, thus avoiding misalignment and improving overall print quality.

What should I consider when comparing UV printers?

When comparing UV printers, consider their visual positioning features, performance metrics, user reviews, and the flexibility they offer in terms of substrate types and print sizes.

Are there UV printers that support multiple substrates?

Yes, many modern UV printers are designed to support a variety of substrates, including flexible and rigid materials, and they often come with specialized features for optimal printing on each type.