The Direct to Film printer, also known as the DTF printer, has transformed the texture sector and upgraded the process of creating graphics on clothing in the digital era. Manufacturers and designers can now develop digital artwork and transfer it into your clothing by printing it on a PET film. But did you know a DTF printer can be a great option to expand your business?

Well, recently, you might have come across arguments debating Direct to Film (DTF)printing versus Direct to Garment (DTG) printing. DTG printing is one of the mature technology and the main method used for T-shirt printing and small finished productions. However, DTF printer has been the latest technique on everyone’s buy list and taking over the custom apparel / personalized garments printing business now. To understand this shift, let’s dive into details, shall we?

As its name suggests, a DTF printer enables you to print the desired design onto a film. Afterward, you transfer it onto the selected surface, like fabric. The reason behind the sudden rise of DTF printing is that it allows you to choose your intended printing surface freely.

Also, the DTF printing technology allows you to easily print on various materials, including polyester, cotton, and synthetic, among others. It works on both white and dark fabric without having to press on costly A&B paper.

If you want to know all details of our all-in-one DTF printer, please visit:

https://www.mtutech.com/DTFPrinter60Plus/DTFSystemMTDTF60Plus-1131.html

Implementing a DTF printer in your garment printing business doesn't require a significant investment. If you’re new to DTF printing solutions, understanding how it works can help you effectively incorporate it to expand your business.

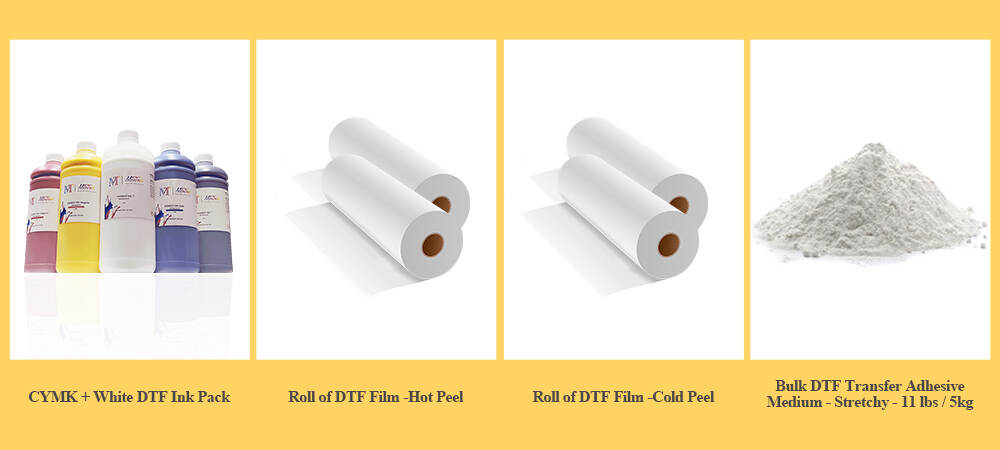

A DTF-modified printer comes with several water-based colored ink tanks. Those tanks enable the printer to conveniently manage using the usual CMYK+W settings. You can use the DTF printer’s ink with the typical CMYK+W process.

Furthermore, the DTF printing process removed the need for rollers, which often led to page sliding. As a result, a Direct to Film printer eliminates the appearance of linings on white-layered prints. Therefore, if you’re looking to improve customer satisfaction by creating inch-perfect final designs that reflect the exact image you intended on their fabric, a DTF printer is all you need.

Now, let’s examine some key features that distinguish a DTF Printer and how they facilitate its operations.

1. The DTF Printer Films

DTF printers use transfer films that differ from the ones used by screen printers. A DTF transfer film is 0.75mm thick, making it a better-transferring feature. These films are commonly referred to as Direct to Film or DTF transfer films.

They are available for small-scale users in cut sheets and big commercial businesses as rolls. The DTF transfer films are classified into two categories, a) cold-peel and (b) hot-peel films, based on temperature.

2. The DTF Printer Software

Software plays an integral role in DTF printers. It determines the inks’ print characteristics, end print performance, and color performance. Typically, DTF printing requires unique RIP software, which handles your CMYK and white colors.

3. Automated Powder Shaker

This DTF printing feature is commonly used by large garment printing businesses. The DTF powder shaker machine plays a crucial role in ensuring a high-quality end product. The above case is so because it applies the powder uniformly while removing the excess powder. Therefore, the shake powder machine ensures that your designs will not have extra powder patches.

4. Heat Press Machine

This machine transfers the printed image from the PET film to the intended fabric. Also, it’s used for heating the DTF film’s hot melt powder.

5. Hot-Melt Adhesive Powder

The DTF printing powder contains white granular and serves as an adhesive product. Also, it helps in binding your printer's colored pigments onto the desired printing surface. There are several hot-melt powder grades identified in microns. Therefore, you should select the appropriate grade depending on the specified requirements.

6. Curing Oven

As its name suggests, a curing oven is a small-scale oven designed to melt the hot-melt powder applied to the DTF transfer film. It serves a similar purpose as the heat press machine.

7. Direct to Film Printer Inks

DTF printers use unique inks designed in black, white, yellow, cyan and magenta colors. However, the white-colored ink creates your print’s foundation, while the rest pigments print your design on the PET film.

You get premium-quality prints with DTF printers thanks to the advanced DTF powder shaker machine and special ink used. Suppose you want to bring out the delicacy and brightness of various color tones. In that case, a DTF printer can help you achieve your wish in both light and dark fabrics.

Investing in a DTF printer is a great way to explore and expand your business. The following are some advantages of investing in a DTF Printer.

üNo pretreatment is needed. Pretreatment is a major downside of most printing technologies, including DTG. However, DTF printers need no pretreatment. As a result, you can take a garment from your rack and directly throw it in the heat press machine, regardless of the number of other pre-printed designs.

üThe entire printing process is quicker and less tedious. DTF printers combine multiple features needed to expand your business, including quality, high productivity, and reliability. They can handle larger production volumes, a crucial aspect required to grow your business in a fast-growing sector. Its quality results are attributed to the automated shake powder machine, which ensures even hot-melt powder distribution.

üDTF printing offers multiple options. Unlike older printing technologies, DTF printing is compatible with several fabrics, including polyester, cotton, leather, and nylon, just to mention a few. This factor makes DTF printers an ideal choice where versatility is needed in the printing industry.

üA DTF printer is cheaper and more sustainable. DTF printing does not need any advanced settings. It helps you realize a one-off design while eliminating unnecessary waste associated with unsold inventory. Also, it requires lesser space to implement than other printing technologies.

üIt produces more durable prints than DTG. Usually, DTG prints are known for their barely-there and soft hand-feel since the ink is directly applied to the clothing. On the contrary, DTF prints tend to be more durable. They are flexible and wash well. As a result, they won’t peel or crack, making them suitable for heavily used items.

You can use a DTF printer for various purposes. The DTF printing technology involves transferring any type of image, such as logo, artwork, photograph, or design, onto a piece of fabric. With a DTF printer, you can create the following:

üHats

üT-shirts

üBanners and flags

üCoats or hoodies

üPants / shorts

üPrinted tags, among other fabric items.

Get a DTF printer today and start enjoying unlimited printing possibilities.

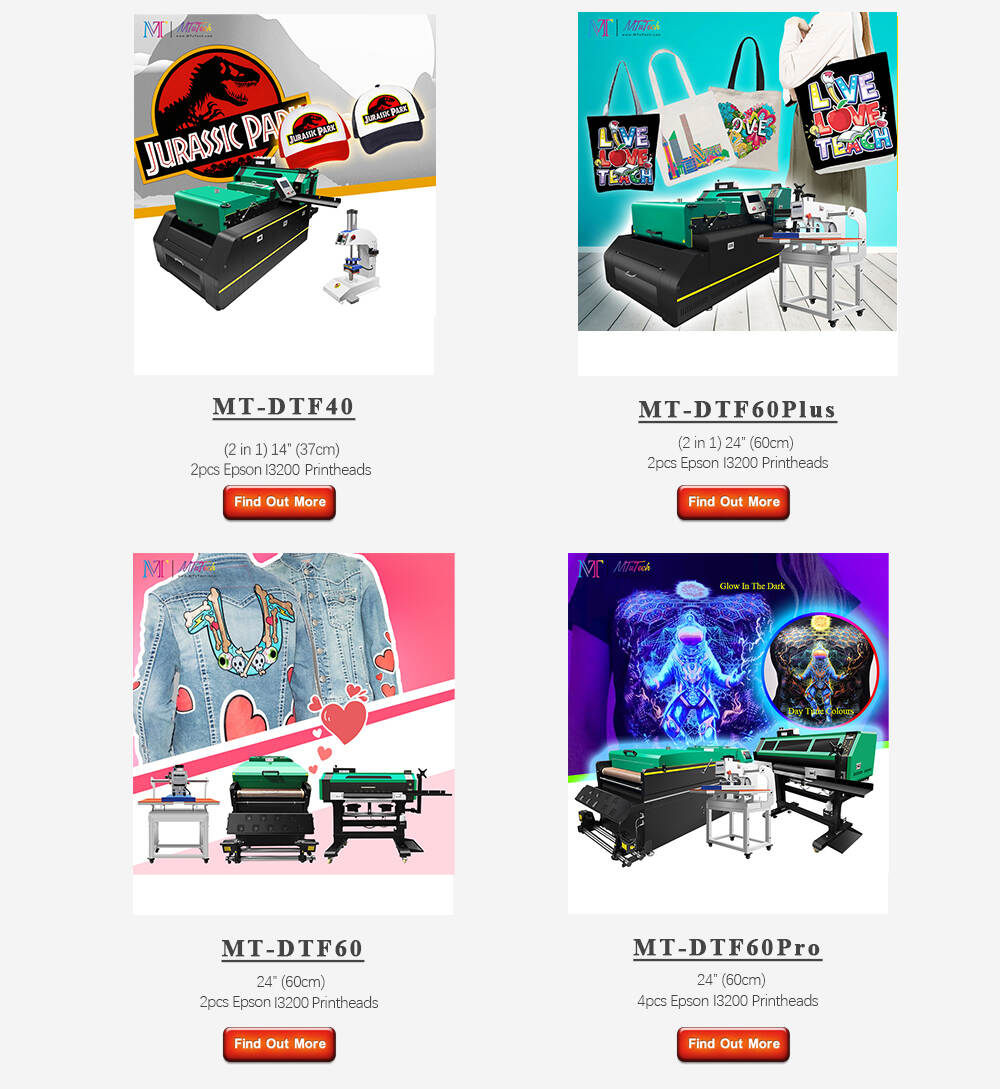

We recommend DTF printer that equips with EPSON I3200 printhead as your top pick DTF printer. Because the nozzle is an important part that determines the quality of a DTF PET Film Printer machine. As a professional printer manufacturer and supplier in China, we can provide a full range of DTF printer with different collocation or combinations, which can meet diverse demands. You can check out more information on our online store here.

Finally, DTF printing is transforming the printing industry, and to be a revolutionary new printing method that’s more affordable and accessible compared to DTG and other traditional printing techniques. It lifts all limitations associated with other printing technologies, especially when selecting the fabric you wish to print on. Take your garment printing business to a new level with DTF printing technology. Enjoy improved printing speeds and inch-perfect prints with DTF printers.