Understanding Cylinder UV Printer Angular Resolution and Registration

Introduction

In the rapidly evolving world of printing technology, cylinder UV printers have emerged as a transformative solution for custom printing needs. These printers are highly effective in producing high-quality images on cylindrical surfaces, including bottles, cans, and other round items. However, to achieve the best results, understanding two key aspects—angular resolution and registration—is crucial. This blog post will delve into these concepts, shedding light on their importance and how they impact the overall printing process.

What is Angular Resolution?

Angular resolution refers to the ability of a printer to resolve fine details in terms of angle within a given surface area. In the context of cylinder UV printing, this means how well the printer can produce intricate designs as the object rotates around its axis. A higher angular resolution results in sharper and more detailed images, which are essential for creating visually appealing products.

Factors Influencing Angular Resolution

·

Print Head Design: The design and technology of the print head significantly impact angular resolution. Modern print heads allow for precision droplet placement, leading to better detail.

·

·

DPI Settings: Dots Per Inch (DPI) settings also play a crucial role in determining angular resolution. Higher DPI settings usually yield better detail and definition.

·

·

Media Type: The surface texture and material of the object being printed on influence how detailed the final image appears. Smooth surfaces tend to result in better angular resolution.

·

·

Ink Viscosity: The type and viscosity of the ink used can affect how well it adheres to and spreads on the surface, impacting overall image quality.

·

Understanding Registration in Cylinder Printing

Registration refers to the alignment of the image or design on the cylindrical object during the printing process. Accurate registration ensures that all colors and layers of the print are positioned correctly, which is especially critical when multiple colors or layers are used. Misalignment can lead to blurry images and poor-quality prints, which can affect the product's appeal.

The Importance of Registration

·

Color Accuracy: Proper registration allows for consistent color application and enhances the visual appeal of the final product.

·

·

Brand Consistency: For businesses that rely on specific designs and logos, maintaining the correct registration is vital for brand identity.

·

·

Overall Quality: Good registration contributes to a polished, professional appearance that can make a significant difference in consumer perception.

·

How to Achieve Optimal Angular Resolution and Registration

Here are some best practices for achieving optimal angular resolution and registration in cylinder UV printing:

1. Use High-Quality Equipment

Investing in a high-quality cylinder UV printer equipped with advanced technology will significantly improve both angular resolution and registration. Look for printers with adjustable DPI settings and sophisticated print head designs.

2. Regular Maintenance

Regularly maintaining your printer is essential for optimal performance. This includes cleaning the print heads, ensuring proper ink flow, and calibrating the printer for specific media types.

3. Training and Expertise

Ensure that operators are well-trained in the functionalities of the printer and understand the intricacies of achieving optimal resolution and registration. Knowledge of how to set the printer for different types of media can make a notable difference.

4. Test Prints

Perform test prints before executing larger production runs. This step allows you to assess whether the registration and resolution meet your quality standards and make necessary adjustments.

5. Use Software for Precision

Employ design software that allows for accurate measurements and adjustments. Software can also help visualize how designs will wrap around cylindrical objects, ensuring proper alignment before the print process begins.

Benefits of Improved Angular Resolution and Registration

Enhancing angular resolution and registration can yield numerous benefits:

Quality Control

Better control over resolution and registration leads to higher quality prints, thereby reducing waste and increasing customer satisfaction.

Cost-Effectiveness

Though it may require an initial investment, improving these aspects can lead to long-term cost savings by minimizing errors and reprints.

Brand Reputation

Consistently high-quality printing reinforces brand reputation, making customers more likely to return and refer others to your products.

Market Competitiveness

In a competitive marketplace, having superior print quality can set your products apart, giving you an edge over competitors.

Conclusion

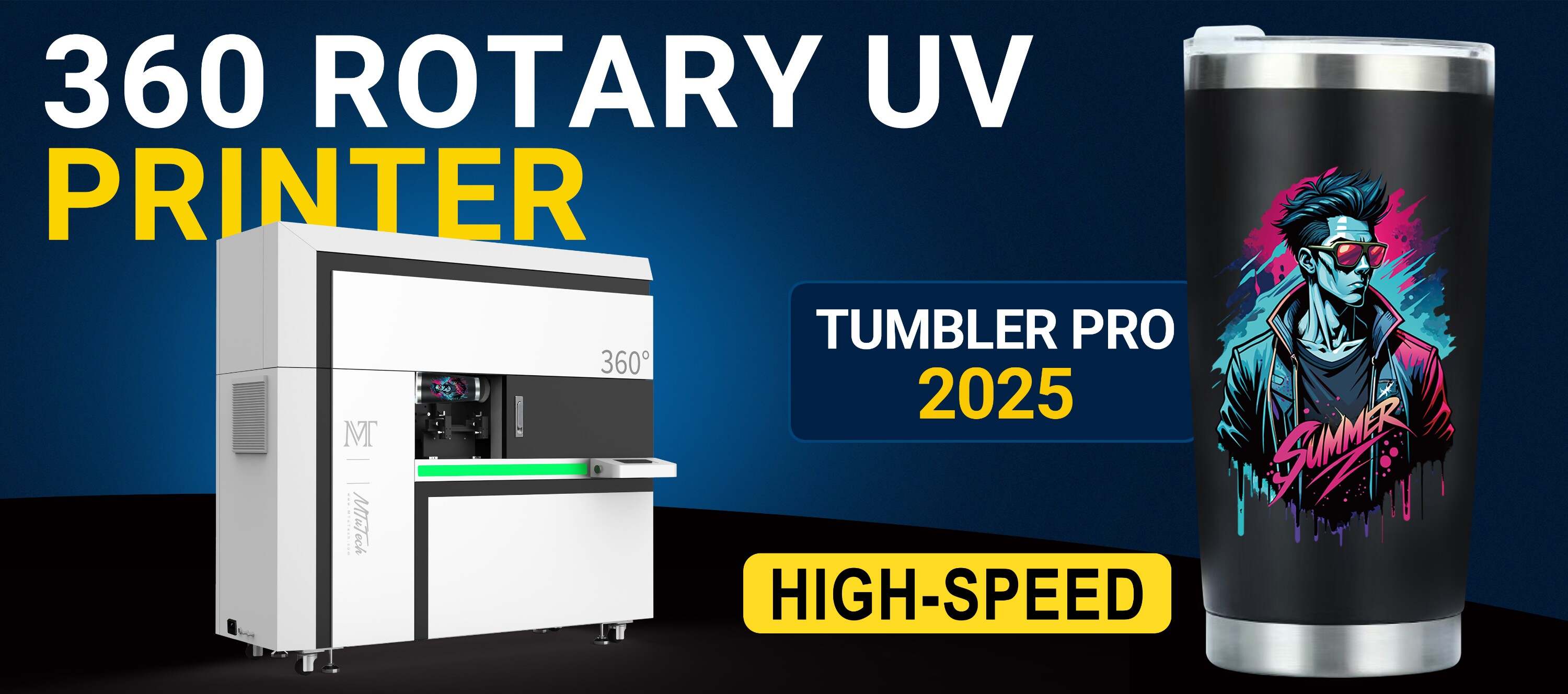

Understanding cylinder UV printer angular resolution and registration is fundamental for businesses aiming to excel in custom printing solutions. By focusing on the factors that influence these aspects and implementing best practices, you can ensure superior print quality and customer satisfaction. As you continue exploring various printing technologies, consider how enhancements in resolution and registration can benefit your projects and overall business strategy. For those interested in investing in top-notch printing solutions, explore our high-quality Cylinder UV printers here.

FAQ

What is the significance of angular resolution in cylinder printing?

Angular resolution determines the level of detail and sharpness achievable in printed images on cylindrical surfaces. Higher angular resolution ensures that intricate designs are reproduced clearly and accurately.

How does registration affect print quality?

Registration is the alignment of colors and layers during printing. Accurate registration prevents blurriness and misalignment, ensuring that the final product maintains a high-quality appearance.

Can I improve registration in my existing cylinder UV printer?

Yes, you can improve registration by regularly maintaining your equipment, utilizing high-quality materials, and ensuring all operators are trained effectively in the printing process.

What role does media type play in achieving optimal resolution?

The type of media used can significantly influence the angular resolution. For best results, selecting smooth, compatible media can help to create detailed, high-quality prints.

Are there specific software tools to help with design and registration?

Yes, many design software applications are available that provide tools for precise measurements and help visualize designs on cylindrical objects, ensuring better alignment before printing.