Introduction

In the world of printing technology, UV DTF (Direct to Film) has emerged as a popular choice for producing vibrant, high-quality prints on a variety of surfaces. As printers evolve, many enthusiasts and business owners wonder if they can convert their existing inkjet printers into UV DTF printers. This blog post will explore the conversion process, its benefits, and provide insights into whether it’s a feasible option for your printing needs.

What is UV DTF Printing?

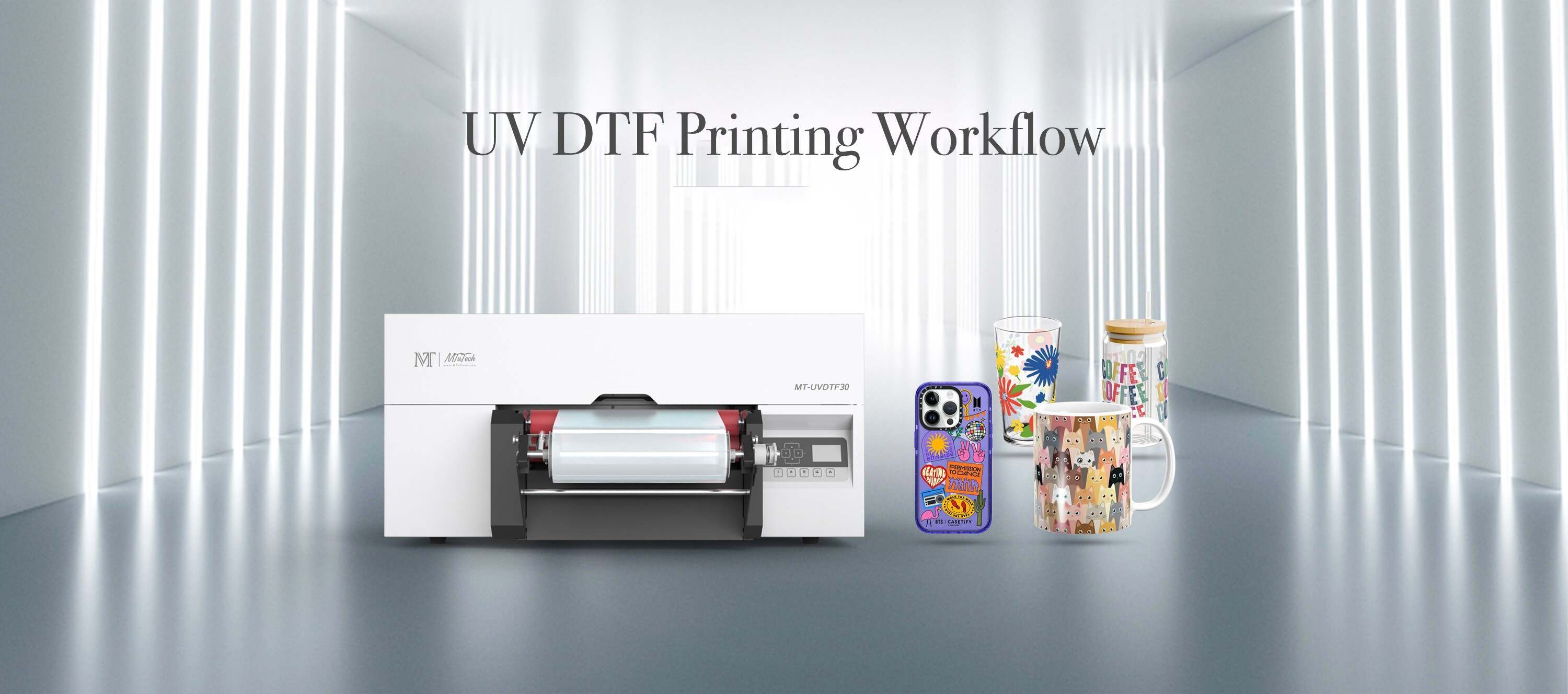

UV DTF printing is a technique that involves printing designs onto a special film, which is then cured with UV light. This process allows for high-detail images, vibrant colors, and the ability to print on diverse materials such as fabrics, plastics, and even glass. It differs from traditional DTF printing by utilizing UV curing technology, making it more versatile in terms of substrates.

Can You Convert a Printer to UV DTF?

Understanding Conversion Possibilities

The idea of converting a standard inkjet printer to a UV DTF printer is appealing, especially for those looking to save costs or maximize their equipment's potential. While it is possible, the conversion process is not straightforward and comes with its own set of challenges.

Key Considerations for Conversion

Printer Compatibility: Not all printers are suitable for UV DTF conversions. Ideally, you should begin with a printer that has a high-quality inkjet mechanism capable of handling the thickness of special UV inks.

Ink Type: You will need to replace your standard ink with UV-curable ink. UV inks are fundamentally different from water-based or solvent-based inks and require specific handling and printing conditions.

Curing System: Traditional printers do not come equipped with UV curing mechanisms. You may need to integrate a UV lamp or curing station into your setup, which can add to the complexity and cost.

Cost vs. Benefit: Consider whether the investment in conversion components will pay off compared to investing in a dedicated UV DTF printer.

Benefits of UV DTF Printing

Despite the challenges associated with conversion, UV DTF printing comes with several benefits that make it an attractive option:

Superior Durability: UV printing produces resilient and long-lasting prints that can withstand exposure to elements, making them ideal for both indoor and outdoor applications.

Quick Drying Time: The UV curing process results in immediate drying of prints, increasing efficiency and reducing production time.

Wide Material Compatibility: UV DTF can print on a broad range of substrates, from textile to rigid materials, allowing you to expand your product offerings.

Vibrant Colors and Fine Detail: Achieve stunning color accuracy and intricate detail in prints, ensuring high-quality results for your customers.

Features to Look for in a UV DTF Printer

If you decide that converting your existing printer is not the right route, consider the following features when searching for a UV DTF printer:

High Resolution: Look for printers capable of high dpi (dots per inch) to ensure crisp and clear prints.

Variable Ink Drop Technology: This feature allows for better ink management, resulting in more vibrant colors and reduced ink waste.

Wide Print Size Capability: Depending on your needs, a printer with a larger print bed will offer greater flexibility for various projects.

Built-in Curing System: An integrated UV curing station can simplify the printing process and reduce the need for additional equipment.

Steps to Convert Your Printer to UV DTF

1. Research Printer Compatibility

Not all printers are created equal, so the first step is to determine if your current printer can handle UV inks and has the necessary printhead technology.

2. Purchase UV Inks

You will need to invest in UV-curable inks specifically designed for your printer model. Ensure compatibility to avoid issues during printing.

3. Modify the Ink Delivery System

Most likely, you'll need to replace or modify the ink delivery system to work with the thicker UV inks. This may involve changing the ink lines or refitting the printhead.

4. Integrate a UV Curing System

Without a curing system, UV DTF printing is impossible. Consider investing in a UV lamp or curing unit that matches the size and specifications of your printer.

5. Calibrate and Test

After making the modifications, it's crucial to conduct thorough tests to calibrate the printer settings for the new inks and curing system to achieve optimal print quality.

Potential Pitfalls of Converting a Printer

While converting a printer to UV DTF may seem enticing, there are potential pitfalls:

Quality Issues: The conversion process may not yield the same quality as a purpose-built UV DTF printer, particularly in color vibrancy and detail.

Maintenance Challenges: UV inks can require different maintenance practices than standard inks, potentially leading to clogs or other issues.

Warranty Voids: Modifying your printer may void the manufacturer's warranty, leading to costly repairs without support.

Conclusion

Converting a standard printer to a UV DTF printer is a task that holds both promise and challenges. While it is possible, the complexity of making these modifications may lead more people to consider investing directly in dedicated UV DTF printers. For those willing to tackle the conversion with the right knowledge and materials, it can be a rewarding project that unlocks new printing capabilities. However, for most users, purchasing a high-quality UV-DTF printer may be the more efficient and reliable option.

If you're ready to take the plunge into UV DTF printing, consider your options carefully.

Explore our high-quality UV-DTF printers here.

FAQ

Is it worth converting my printer to UV DTF?

It depends on your specific needs and the costs associated with conversion. If your current printer is compatible and you’re willing to invest in UV inks and curing systems, it may be worth it. However, dedicated UV DTF printers are specifically designed for this type of work, often yielding better results.

How long does it take to convert a printer?

The time required for conversion can vary based on your technical skills and the type of printer. Generally, it may take a few hours to properly modify the printer and integrate the new system, followed by additional time for calibration and testing.

What types of materials can I print on with UV DTF?

UV DTF printing can be used on a wide variety of materials, including but not limited to fabric, plastic, glass, wood, and metal. This versatility makes it an appealing option for many businesses.

Will converting my printer affect its lifespan?

Potentially, yes. Converting a standard inkjet printer can lead to wear and tear if not done correctly. Furthermore, using UV inks may require different maintenance, which could affect overall longevity if not properly addressed.

Can I use my UV DTF printer for regular printing tasks?

While technically you can switch between UV DTF and standard printing tasks, it’s not always practical. The ink used in UV DTF printers is different, and frequent switching may lead to problems like clogging or inconsistent quality.