Introduction

In today's fast-paced printing industry, innovation is key to staying ahead of the competition. One of the advancements making waves is the UV Direct to Film (DTF) printer. This cutting-edge technology expands the possibilities of custom printing, allowing businesses to create vibrant, durable prints on a wide range of surfaces. In this blog post, we will explore what UV DTF printers are, how they work, their benefits, features, and why they are becoming an essential tool for businesses in various sectors.

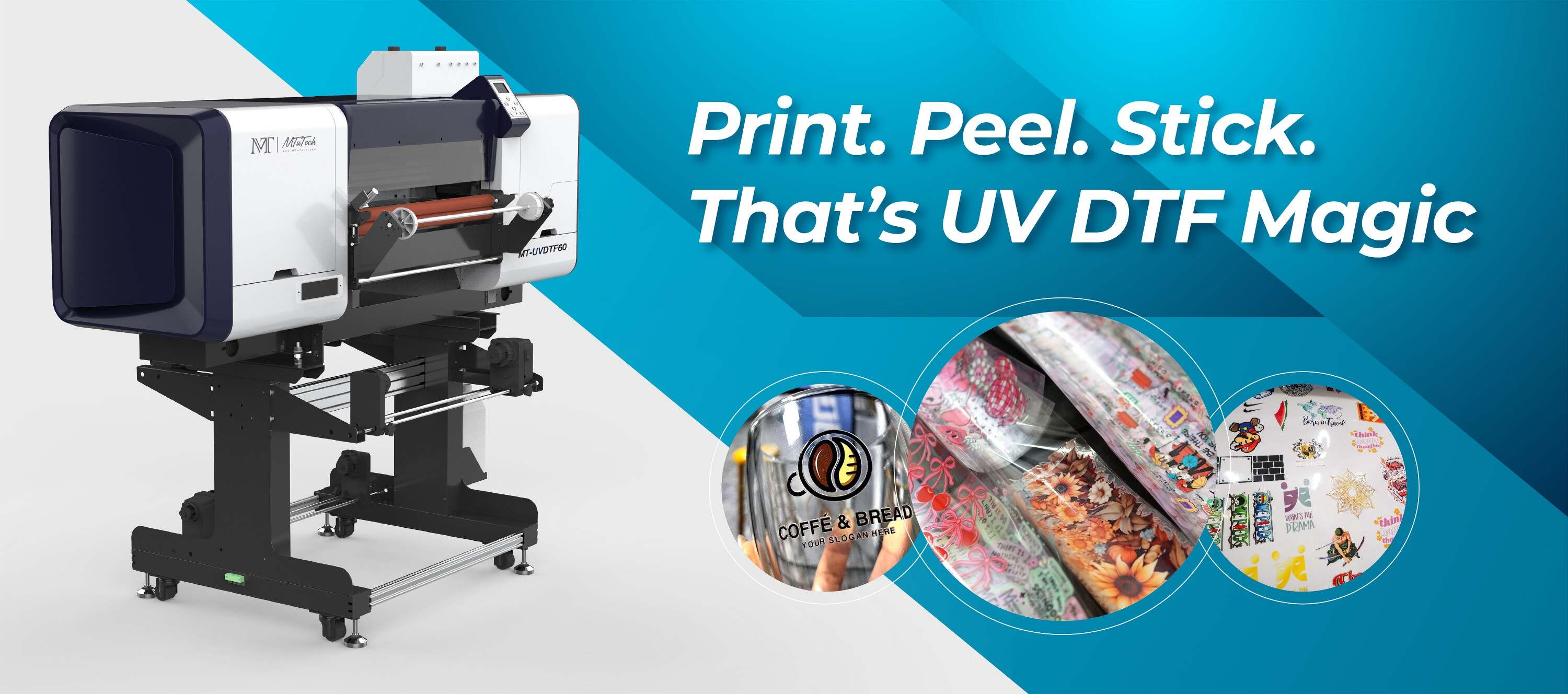

What is a UV DTF Printer?

A UV DTF printer is a type of printing technology that combines direct-to-film printing and ultraviolet (UV) curing. It allows for the output of high-quality imagery on specially coated films, which are then transferred to a substrate using heat and pressure. This process not only provides an excellent finish but also enhances durability and color vibrancy.

How Does UV DTF Printing Work?

The UV DTF printing process involves several steps:

Design Creation: Using graphic design software, you create the desired design, including colors, fonts, and graphics.

Printing: The design is printed onto a transfer film using UV-curable inks. These inks are cured using UV light, making them adhere strong to the film.

Transfer: The printed film is then placed on the chosen substrate (like textiles, wood, or metals) and subjected to heat and pressure to transfer the image.

Curing: The prints are further cured to ensure they are robust and can withstand wear and tear.

Benefits of UV DTF Printing

1. Versatility

One of the standout features of UV DTF printers is their versatility. They can print on a variety of substrates, including:

Textiles

Plastics

Wood

Metals

Glass

This capability allows businesses to expand their product offerings significantly.

2. High-Quality Prints

UV DTF printers produce vibrant colors and sharp details that can meet high-resolution standards. The UV inks ensure that the prints do not fade easily, maintaining their beauty over time.

3. Durability

Printed designs using UV DTF technology are resistant to scratches, water, and various environmental factors. This durability makes UV DTF prints ideal for both indoor and outdoor applications.

4. Cost-Effectiveness

While the initial investment in a UV DTF printer may be higher than traditional printers, the long-term savings are significant. With fewer printing errors, reduced material waste, and the capability to print on demand, businesses can maximize their profitability.

5. Environmentally Friendly

UV DTF printers use UV-curable inks, which are less harmful to the environment compared to traditional solvent-based inks. Additionally, the reduction in waste contributes to a more sustainable printing process.

Key Features of UV DTF Printers

1. Printer Head Technology

Modern UV DTF printers employ advanced print head technology to achieve high resolution and precision in printing. This technology helps in producing intricate designs with fine details.

2. Adjustable Curing Settings

Many UV DTF printers come with adjustable curing lamps that allow for precise control of the curing process, ensuring optimal adhesion of prints to different materials.

3. Multi-layer Printing

Some advanced models support multi-layer printing, enabling businesses to experiment with textures and effects that enhance the depth of the prints.

4. User-Friendly Interfaces

Today’s UV DTF printers often feature user-friendly interfaces that allow operators of all skill levels to easily navigate settings and manage printing tasks effectively.

5. Improved Ink Configuration

UV DTF printers have various ink configurations that allow for a wide color gamut and increased versatility, enabling businesses to produce custom orders efficiently.

Applications of UV DTF Printers

UV DTF printers have a multitude of applications, making them suitable for various industries, including:

Apparel Industry: Ideal for t-shirts, jackets, and custom apparel.

Promotional Products: Perfect for creating customized promotional items like bags, mugs, and keychains.

Interior Decor: Used for printing wallpapers, custom decor, and furnishings.

Commercial Signage: Effective for indoor and outdoor signage that requires durability and color longevity.

Choosing the Right UV DTF Printer

Selecting the right UV DTF printer involves assessing several factors based on your business requirements:

Print Volume: Determine the expected print volume and choose a printer that can handle your workload efficiently.

Budget: Factor in not just the machine cost but also operational costs, such as ink and maintenance.

Print Quality: Look for printers that offer high-resolution capabilities if you aim for intricate designs and photos.

Material Compatibility: Ensure that the printer can handle the materials you plan to print on.

With these factors in mind, you can select a UV DTF printer that will meet your needs and add value to your business.

Conclusion

UV DTF printers represent the future of printing technology, combining innovation with versatility and durability. Whether you are in the apparel industry, promotional products, or any other sector that requires high-quality prints, investing in a UV DTF printer can significantly enhance your business capabilities. With their ability to produce vivid colors and durable prints, they are an essential tool for any printing professional.

As you consider upgrading your printing operations, remember to explore our high-quality UV-DTF printers to find the perfect fit for your business needs. Embrace the changes in printing technology, and reap the benefits it brings!

FAQ

What is the difference between UV DTF printing and traditional DTF printing?

UV DTF printing uses UV-curable inks that dry quickly upon exposure to UV light, resulting in more durable and vibrant prints on a wider array of materials. Traditional DTF printing relies on water-based inks that require a different curing process and may not be as versatile.

Can UV DTF printers print on dark materials?

Yes, UV DTF printers can print on dark materials thanks to the use of white ink as a base layer. This feature allows for better coverage and visibility of colors on dark substrates.

What maintenance is required for UV DTF printers?

Maintenance typically includes regular cleaning of the print heads, ensuring the ink systems are functioning correctly, and conducting routine checks on the curing lamps. Keeping the printer in a dust-free area can also help maintain its performance.

Are UV DTF prints washable?

Yes, UV DTF prints are generally washable and durable. However, it is important to follow the recommended washing instructions to ensure longevity and preserve the print quality.

How much does a UV DTF printer cost?

The cost of a UV DTF printer can vary widely, depending on features and capabilities. Entry-level models may start from around $5,000, while high-end professional models can cost upwards of $20,000. It's essential to evaluate your budget and needs when considering an investment.