Introduction

In recent years, UV DTF (Direct to Film) printing has emerged as a revolutionary technique in the world of printing. It combines the best features of UV printing and DTF technology, offering vibrant colors, durability, and versatility across various surfaces. This guide aims to provide a clear understanding of how to print using UV DTF methods, along with the steps, benefits, and tips to ensure the best output.

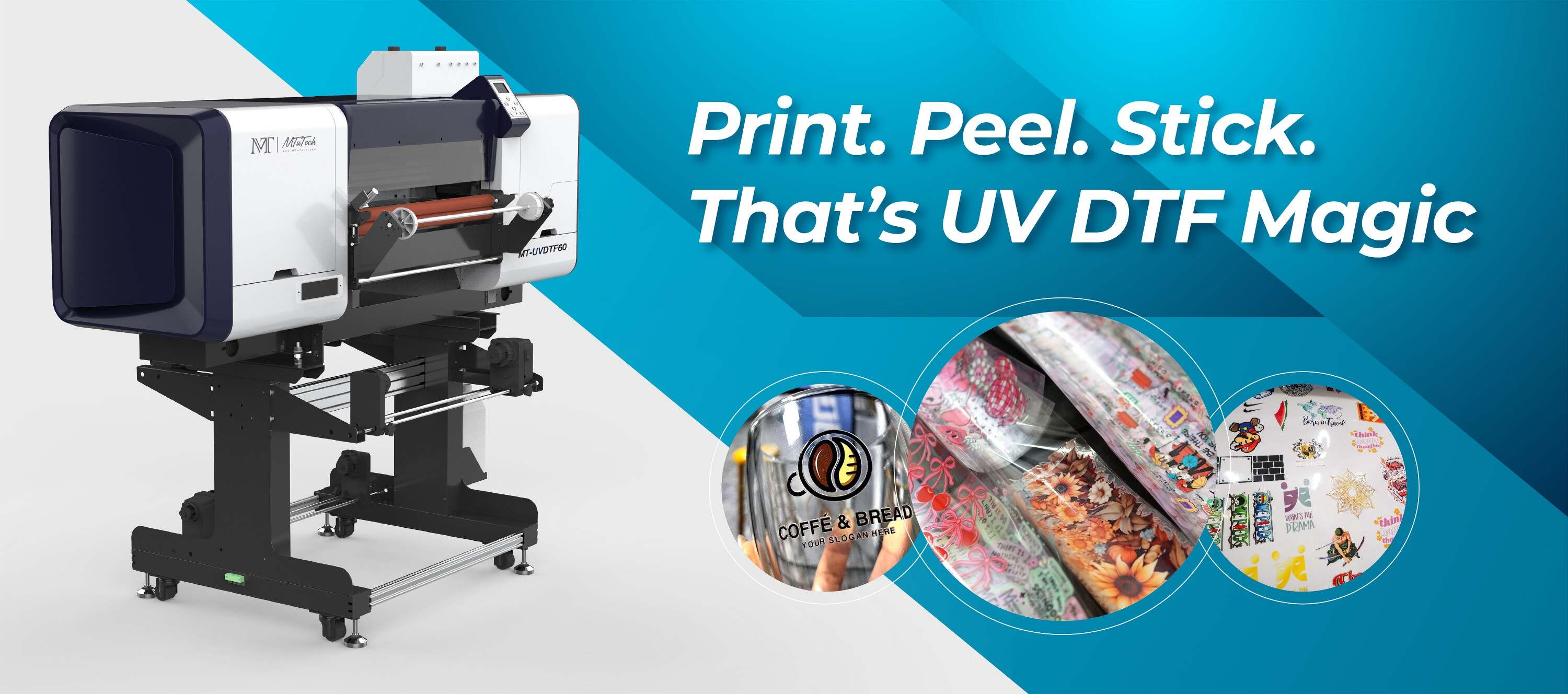

What is UV DTF Printing?

UV DTF printing involves transferring designs from a film onto various substrates using UV light for curing. Unlike traditional methods, this technique allows for a more flexible approach to printing on materials like plastic, wood, metal, and textiles.

Benefits of UV DTF Printing

The UV DTF printing method offers several advantages that make it stand out in the printing industry:

Vibrant Colors: UV DTF printing produces vivid and high-quality images that maintain their colors over time.

Durability: The UV-cured inks are resistant to scratches, fading, and other forms of wear, making them ideal for both indoor and outdoor applications.

Versatility: This technique can be used on a wide variety of surfaces, including non-porous materials.

Eco-Friendliness: UV inks produce fewer VOCs (volatile organic compounds) compared to traditional inks, making it a more environmentally sound choice.

Less Waste: The DTF process results in less ink waste as it precisely applies the ink only where needed.

Features of UV DTF Printers

When considering UV DTF printing, it's essential to understand the features that contribute to its efficiency and quality:

Print Head Technology: Advanced print heads allow for high-resolution printing, ensuring detail and clarity.

Ink Types: Use specially formulated UV inks that cure instantly under UV light for longevity and brilliance.

Software Compatibility: Look for printers that are compatible with popular design software, making the design process seamless.

Flexible Film Options: Choose between various film types for different applications, enhancing versatility.

Automatic Height Adjustment: This feature helps maintain consistent print quality on various substrates.

Steps to Print Using UV DTF

Let’s dive into the detailed process of UV DTF printing:

Step 1: Prepare Your Design

Begin by creating your design using graphic design software such as Adobe Illustrator or CorelDRAW. Ensure the design is in a high-resolution format to avoid pixelation during the printing process.

Step 2: Print the Film

Once your design is ready, load your UV DTF printer with the film. Adjust the printer settings to match the type of film you are using. Make sure to select the correct media type and resolution for optimal results. Begin printing your design onto the film:

Check ink levels and perform print head maintenance if necessary.

Set the appropriate print speed and curing time according to your printer’s specifications.

Step 3: Apply Adhesive Powder

Immediately after printing, apply an adhesive powder to the film while the ink is still wet. This step is crucial as it helps the design adhere properly to the target substrate. Make sure to spread the powder evenly over the design and shake off the excess.

Step 4: Heat Press the Film

Place the film onto the heated platens of a heat press. The temperature and time settings are typically specified by the printer manufacturer; generally, it ranges between 300°F to 350°F for about 10-15 seconds. This process transfers the ink and adhesive to the substrate effectively.

Step 5: Cure the Print

Post heat-pressing, the print needs to be cured under UV light. This step solidifies the ink and adhesive, ensuring durability and longevity. Allow the print to cool after curing.

Step 6: Final Touches

Finally, inspect your print for quality and make any necessary adjustments. Trim any excess film, and your final product is ready for distribution!

Best Practices for UV DTF Printing

To ensure the best results, consider the following best practices:

Maintain Your Equipment: Regularly clean and maintain your printer to avoid clogs and ensure consistent print quality.

Use Quality Materials: Invest in high-quality films and inks to achieve the best output.

Test Different Settings: Experiment with various print settings to determine what works best for your specific projects.

Stay Updated: Keep abreast of new technologies and materials in the world of UV DTF printing to enhance your capabilities.

Conclusion

UV DTF printing is a transformative process that can help businesses expand their printing capabilities. By following the steps outlined in this guide, you can produce high-quality, durable prints on a variety of surfaces. The versatility and vibrancy of UV DTF printing position it as a formidable choice in the modern printing landscape. If you're considering upgrading your printing capabilities, explore our high-quality UV-DTF printers here and take your business to the next level!

FAQ

What types of materials can UV DTF printing be used on?

UV DTF printing can be utilized on various substrates, including plastics, metals, woods, textiles, and glass. Its versatility makes it suitable for numerous applications.

Is UV DTF printing environmentally friendly?

Yes, UV DTF printing is considered more environmentally friendly than traditional printing methods due to lower VOC emissions and reduced ink waste.

How durable are UV DTF prints?

UV DTF prints are highly durable, offering resistance to scratches, fading, and wear, making them suitable for both indoor and outdoor use.

Do I need special training to operate a UV DTF printer?

While familiarity with printing technology is beneficial, most UV DTF printers come with user manuals and support that make it relatively straightforward to learn how to operate them.

How long does the printing process take?

The entire process from design to final print can vary depending on the size and complexity of the project but typically ranges from a few hours to a full day.