Introduction

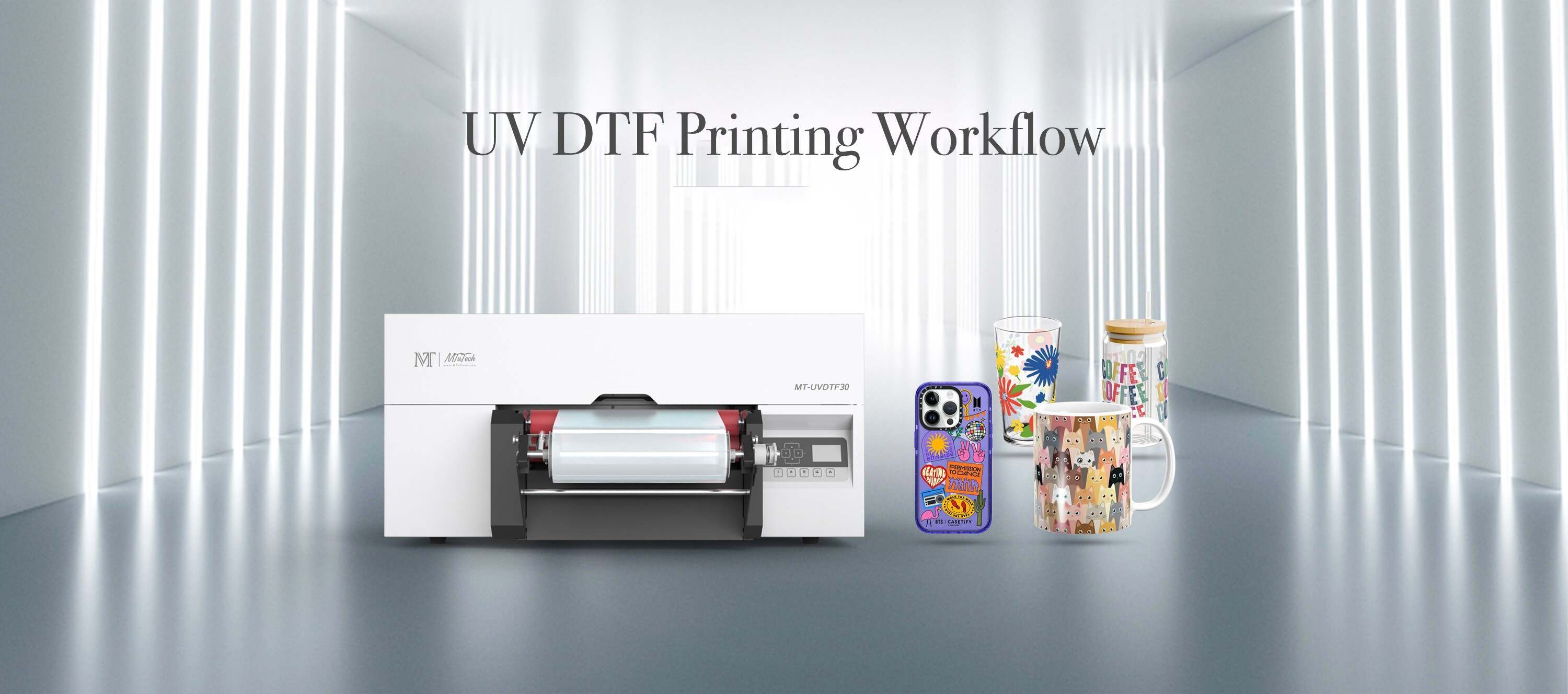

In the world of printing technology, UV Direct to Film (DTF) transfers have become increasingly popular due to their versatility and vibrancy. This printing method allows for high-quality designs to be printed on a variety of substrates, including textiles, ceramics, and metals. With the right tools and knowledge, anyone can successfully print UV DTF transfers. This comprehensive guide will walk you through the process, benefits, and important considerations when working with UV DTF transfers.

What is UV DTF Printing?

UV DTF printing combines the advantages of UV printing and DTF technology. It involves printing a design onto a special transfer film using UV inks, which cure immediately when exposed to UV light. This ensures vibrant colors, sharp details, and durability, making it suitable for both small-scale and large-scale production.

Benefits of UV DTF Transfers

Versatility: UV DTF transfers can be applied to various substrates, including textiles, plastics, glass, and wood.

Durability: UV inks provide excellent adhesion and resistance to fading, ensuring long-lasting prints.

High-quality prints: The ability to create detailed designs with vibrant colors enhances the overall appeal of the finished product.

Quick turnaround time: The curing process is fast, allowing for quicker production times compared to traditional printing methods.

Essential Equipment for UV DTF Printing

1. UV DTF Printer

Investing in a high-quality UV DTF printer is crucial, as it directly affects the quality of your prints. These printers are specifically designed to handle UV inks, ensuring optimal performance and durability. Explore our high-quality UV-DTF printers here to find the perfect model for your needs.

2. Transfer Film

Choose a transfer film that is compatible with UV inks. The film should be of high quality to ensure smooth transfer and accurate color reproduction.

3. UV Inks

UV inks are specially formulated for use in UV DTF printing. They cure under UV light, providing excellent adhesion and vibrant colors. Ensure that your inks are designed for DTF applications.

4. Light Source

A reliable UV light source is essential for curing the inks quickly and effectively. This could be built into your printer or as a separate curing station.

5. Heat Press (optional)

Depending on your specific application, a heat press may be required to ensure the transfer adheres properly to the substrate.

Step-by-Step Process for Printing UV DTF Transfers

Step 1: Prepare Your Design

Start by creating or selecting a high-resolution design. Use graphic design software like Adobe Illustrator or CorelDRAW to prepare your artwork. Ensure it meets the printer's specifications, including the correct color profile and resolution.

Step 2: Print the Design

Load the transfer film into your UV DTF printer. Make sure the printer settings are appropriately configured for your type of film and design. After the settings are adjusted, proceed to print the design onto the transfer film.

Step 3: Cure the Ink

Once the design is printed, the next step is to cure the ink. If your printer has an integrated curing system, this will happen automatically. If not, place the printed film under a UV light source for the recommended duration to cure the inks fully.

Step 4: Applying the Transfer

Position your substrate under the transfer film. If needed, use a heat press to ensure the transfer adheres properly. Follow the manufacturer’s guidelines regarding temperature and pressure settings, typically at around 320°F (160°C) for 10-15 seconds.

Step 5: Finishing Touches

After the transfer is applied, allow it to cool down. If necessary, trim any excess transfer film around the design for a cleaner look. Inspect the transfer for quality and adhesion before final use.

Considerations When Printing UV DTF Transfers

Substrate Compatibility: Ensure your chosen substrate is compatible with UV inks to achieve the best results.

Environmental Factors: Control the printing environment, including humidity and temperature, to avoid issues during the printing process.

Maintenance: Regularly clean your printer and maintain its components to ensure optimal performance and extend its lifespan.

Testing: Conduct test prints before moving on to final production to identify and resolve any potential issues.

Conclusion

Printing UV DTF transfers is a fantastic way to create vibrant, high-quality designs on a variety of substrates. With the right equipment and techniques, you can harness the full potential of this innovative printing method. By following the steps outlined in this guide, you can achieve stunning results and expand your creative possibilities. Whether you're a small business owner looking to diversify your product offerings or a craft enthusiast wanting to experiment with new printing technology, UV DTF printing offers endless opportunities.

FAQ

What is the difference between UV DTF and traditional DTF printing?

UV DTF printing uses UV-cured inks that adhere to the transfer film and substrate through UV light exposure, while traditional DTF printing typically uses water-based inks that require a powder adhesive and heat press for transfer.

Can UV DTF prints be washed?

Yes, UV DTF prints are generally durable and resistant to washing. However, it's advisable to follow the proper care instructions for the specific substrate to ensure longevity.

How long does the curing process take?

The curing time depends on the printer and UV light source used. Most printers cure the inks in seconds, while external UV light sources may require longer exposure times. Always refer to the manufacturer’s guidelines for optimal curing times.

Do I need a heat press for UV DTF printing?

While a heat press can improve adhesion and ensure a smooth transfer, it's not always necessary. It depends on the substrate being used. Always consult the transfer film's instructions to determine if heat application is needed.

Where can I buy UV DTF printers and supplies?

You can purchase UV DTF printers and supplies from various online marketplaces and specialized printing equipment retailers. Be sure to choose reputable sources to ensure high-quality products.

By embracing UV DTF printing, you can elevate your projects and create stunning, durable designs that stand the test of time.