Introduction

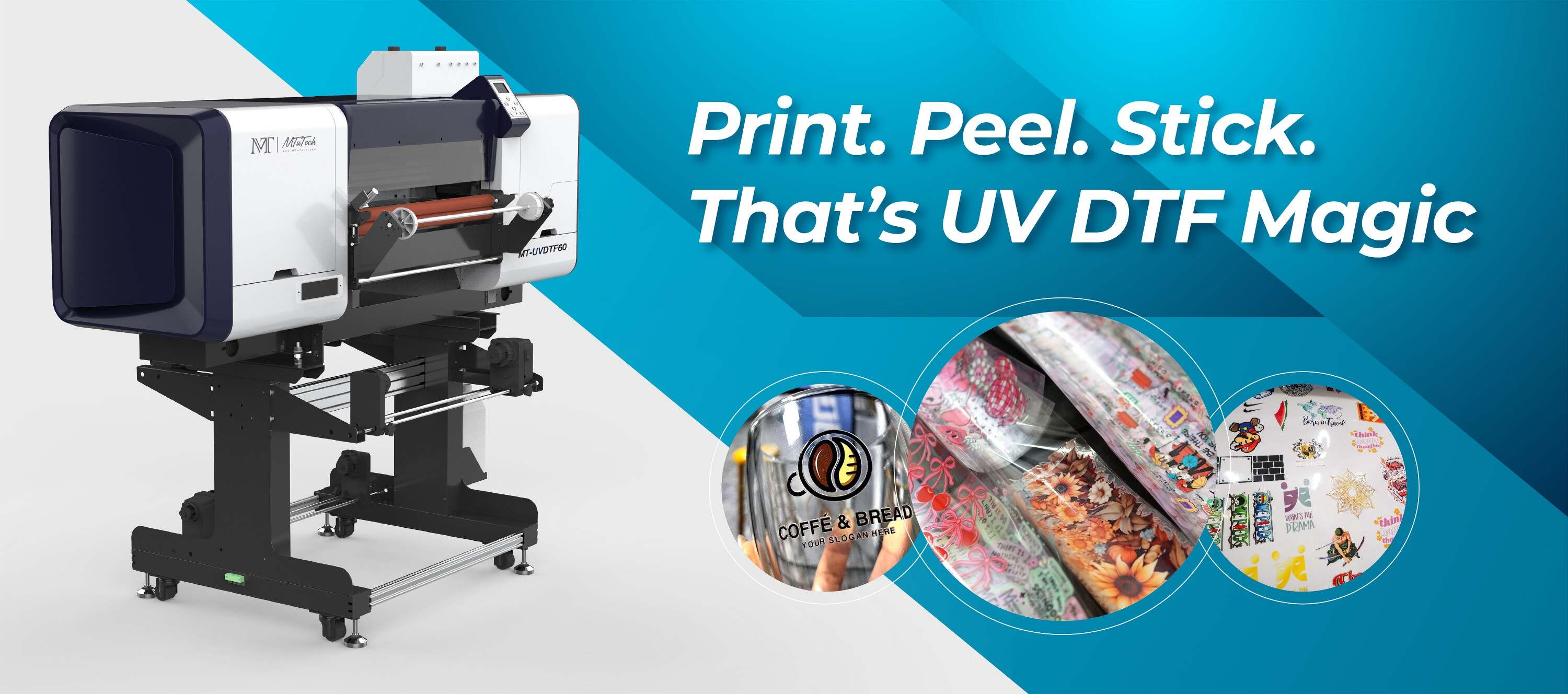

In the ever-evolving world of printing technology, UV Direct-to-Film (DTF) printing has emerged as a game-changer for businesses and manufacturers alike. This innovative printing method combines the advantages of traditional UV printing with the versatility of DTF applications, creating vibrant designs that can adhere to a variety of substrates. In this blog, we will delve deep into the UV DTF printing process, exploring its benefits, features, and what sets it apart from other printing techniques.

What is UV DTF Printing?

UV DTF printing is a specialized technique that uses ultraviolet light to cure ink as it is printed onto a film. Unlike traditional printing methods, which may require heat or pressure to set an image, UV curing instantly dries the ink using UV light. This allows for faster production times and the capability to print on a wide range of materials, including textiles, plastics, metals, and more.

Understanding the UV DTF Printing Process

The UV DTF printing process involves several key stages that contribute to its efficacy and quality. Let’s break this down step-by-step:

1. Design Preparation

The process begins with the design phase, wherein graphic designers use software to create or modify images suitable for printing. The design should account for factors such as color profiles, resolution, and the specific substrate on which it will be printed.

2. Film Printing

Once the design is finalized, the next step is to print it onto a special film using a UV DTF printer. This printer uses UV-curable inks, which are ideal for producing vibrant colors and fine detail. The film acts as a medium that captures the image accurately.

3. UV Curing

After the film is printed, it goes through the UV curing process. As the printed film passes under UV lights, the exposed ink is instantaneously cured. This step is crucial, as it helps to ensure that the inks adhere well and are resistant to wear and tear.

4. Transfer to Substrate

Once cured, the printed film can be transferred onto the desired substrate. This can include various materials such as apparel, hard surfaces, or other items. The transfer can be achieved through heat pressing or other adhesive methods, allowing for a strong bond between the print and substrate.

5. Finishing Touches

After the transfer, additional finishing processes may be applied, such as cutting, trimming, or applying protective coatings. This helps to finalize the product, ensuring that it meets quality standards and is ready for use or distribution.

Benefits of UV DTF Printing

UV DTF printing offers numerous advantages that make it a preferred choice for many businesses. Here are some of the key benefits:

High-Quality Output: The UV curing process allows for vibrant colors and sharp details, producing images that stand out.

Diverse Material Compatibility: UV DTF printing can be used on a wide variety of substrates, from textiles to rigid materials.

Instant Cure Times: The UV curing technology allows for immediate handling and processing of prints, significantly reducing production times.

Durability: Prints created through UV DTF are resistant to fading, scratching, and other forms of wear, making them ideal for long-lasting products.

Eco-Friendly Options: Many UV inks are formulated to be more environmentally friendly, reducing VOC emissions compared to traditional inks.

Features of UV DTF Printers

When considering UV DTF printing, it is essential to understand the features that make these printers unique and efficient:

Precision Printing: UV DTF printers are designed for high accuracy, enabling intricate designs and detailed graphics to be printed effortlessly.

Multi-Color Capabilities: Many UV DTF printers come with advanced color management options, allowing for a broader color spectrum and the ability to print white and metallic inks.

User-Friendly Interface: Modern UV DTF printers feature intuitive interfaces that simplify the printing process, even for users with limited experience.

Modular Design: Some models allow for customization and upgrades, ensuring that businesses can adapt their equipment as their needs change.

Quality Control Systems: Built-in monitoring features help maintain consistent print quality, automatically adjusting settings as necessary.

Applications of UV DTF Printing

The versatility of UV DTF printing opens doors to countless applications across various industries:

1. Apparel Decoration

The fashion industry uses UV DTF printing for custom T-shirts, hoodies, and other garments, providing vibrant designs and personalized options.

2. Promotional Products

Businesses often employ this printing method for promotional items such as pens, bags, and keychains, offering a high-quality solution for branding needs.

3. Interior Decor

UV DTF printing can be utilized for wall art, home decor items, and even furniture, enabling artistic designs to be produced on various surfaces.

4. Industrial Uses

From manufacturing to custom signage, UV DTF printing is increasingly recognized for its efficiency and durability in producing long-lasting products.

Conclusion

UV DTF printing represents a significant advancement in printing technology, delivering high-quality, versatile, and durable results across numerous applications. As the demand for customized and vibrant prints continues to grow, adopting this technique can help businesses meet customer expectations and stand out in a competitive market. To explore the possibilities that UV DTF printing offers, explore our high-quality UV-DTF printers here and take your printing capabilities to the next level.

FAQ

What is the primary difference between UV printing and DTF printing?

UV printing uses ultraviolet light to cure ink directly on surfaces, while DTF printing transfers images from a film onto a substrate. UV DTF combines elements from both, allowing prints to be cured quickly after being printed onto the film.

How durable are the prints produced by UV DTF printing?

Prints produced through the UV DTF process are highly durable, resistant to fading and scratching, and suitable for a variety of applications, including textiles and hard surfaces.

Can UV DTF printing be used for outdoor applications?

Yes, UV DTF prints are suitable for outdoor use, provided they are applied to weather-resistant substrates and are adequately cured. This characteristic makes them ideal for outdoor signage and promotional items.

Is UV DTF printing eco-friendly?

Many UV inks used in DTF printing are formulated to be more environmentally friendly, producing fewer volatile organic compounds (VOCs) compared to traditional inks. Always check the specific ink and printer specifications for eco-friendly compliance.

What types of substrates can be used with UV DTF printing?

UV DTF printing is versatile and works well with various substrates, including textiles, plastics, metals, wood, glass, and more, making it suitable for diverse applications across different industries.