Introduction

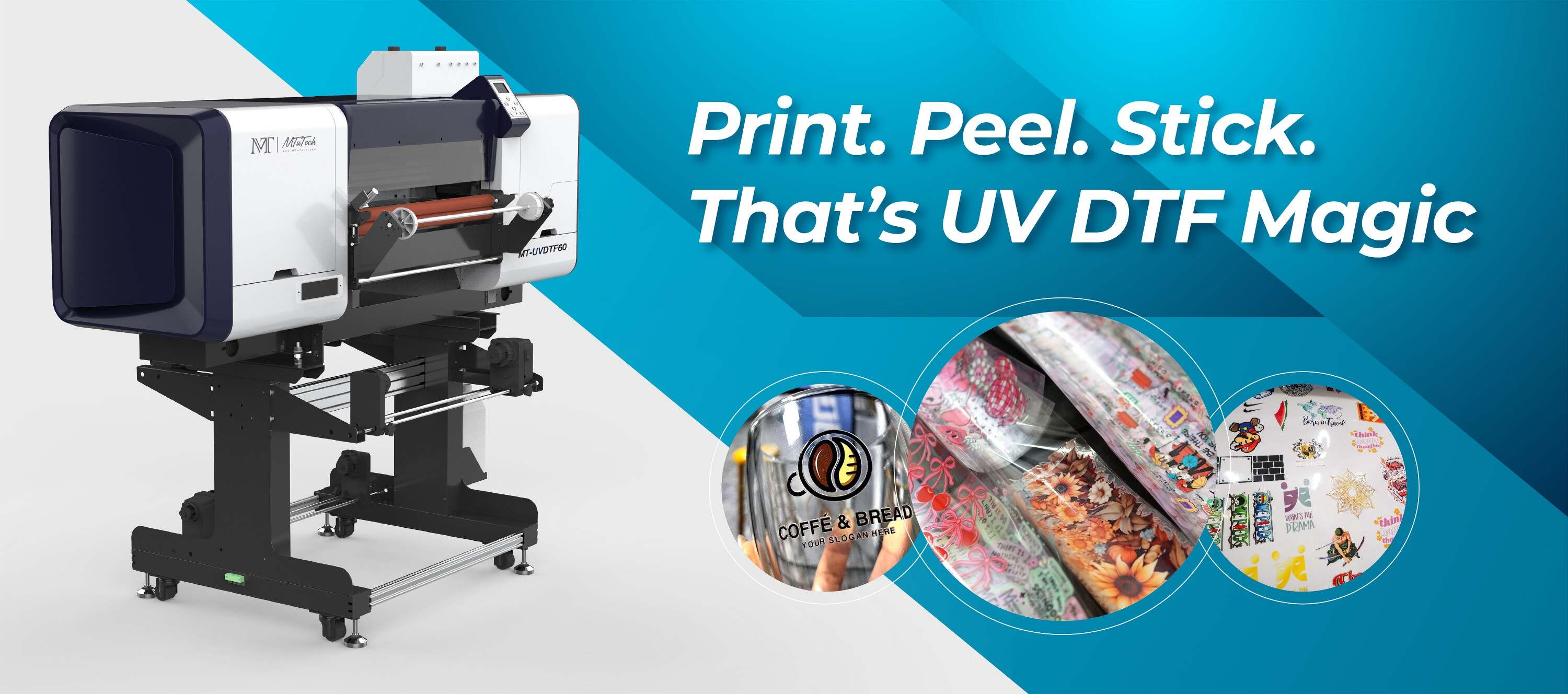

In recent years, UV DTF (Direct-to-Film) printers have gained significant popularity among businesses looking for efficient, high-quality printing solutions. These printers utilize ultraviolet light to instantly cure inks, creating a durable and vibrant finish on various surfaces. If you're considering investing in a UV DTF printer, it's essential to understand the key features that can influence your buying decision. This guide will help you navigate the complexities of choosing the right UV DTF printer for your needs.

Benefits of UV DTF Printers

Before diving into the specific features, let’s explore the benefits of using UV DTF printers.

Versatility: UV DTF printers can print on a wide range of materials, including plastics, metals, glass, and fabrics.

Durability: The UV curing process results in prints that are resistant to scratching, fading, and water damage.

Quality: High-resolution printing provides exceptional detail and color vibrancy.

Environmentally Friendly: UV inks are often less harmful than traditional solvent-based inks.

Instant Drying: The UV curing process allows for immediate handling of printed items.

Key Features to Consider

When selecting a UV DTF printer, it’s essential to focus on specific features that best suit your printing needs. Here are the essential components to consider:

1. Print Quality

One of the most critical factors in your purchasing decision is print quality. Look for printers with high DPI (dots per inch) capabilities, typically ranging from 1200 to 1440 DPI. A higher DPI ensures detailed images and crisp text, which is crucial for professional applications. Additionally, check for color calibration options that ensure consistent and accurate color reproduction.

2. Print Size

The maximum print size is another key feature to consider. Determine the largest items you plan to print and choose a UV DTF printer that accommodates those dimensions. Printers typically range from smaller desktop models suitable for custom items to larger industrial units capable of producing banners and signage.

3. Speed and Productivity

Assess the printer’s speed, measured in square feet per hour (sq ft/hr). For heavy-duty usage or business environments where time is of the essence, opt for a printer with higher speed ratings. Balance speed with quality; sometimes, faster prints might sacrifice detail.

4. Ink Type and Cost

Different UV DTF printers use various ink types, including eco-solvent, UV-curable, and pigment inks. Each type has its advantages and disadvantages. Eco-solvent inks tend to be more budget-friendly, while UV inks provide superior durability. Evaluate the ink costs, availability, and compatibility with your chosen printer.

5. Build Quality and Design

Build quality influences the printer's longevity and reliability. Look for printers made from durable materials that can withstand frequent use. Additionally, consider the printer's design. A compact design may be suitable for smaller workspaces, while larger models may offer more features but require more space.

6. User-Friendly Interface

A user-friendly interface with intuitive controls can significantly enhance your printing experience. Look for printers with touchscreen panels, straightforward navigation, and integrated software that simplifies the design-to-print process. It’s also beneficial to have options for direct USB or network printing.

7. Maintenance and Support

Consider the maintenance requirements of the printer. Some models come with built-in self-cleaning functions, which can save time and reduce downtime. Additionally, evaluate the manufacturer's support options, such as customer service responses, warranty periods, and the availability of replacement parts.

8. Software Compatibility

Ensure that the UV DTF printer you choose is compatible with the design software you intend to use. Many printers come with proprietary software, but you may also want to use popular graphic design software like Adobe Illustrator or CorelDRAW. Confirm that drivers and support for various operating systems (Windows, macOS) are available.

9. Cost and ROI

Finally, consider the overall cost of the printer and its potential return on investment (ROI). While it may be tempting to choose the cheapest option available, evaluate the long-term costs, including maintenance, ink, and consumables. Calculate how many prints you need to produce to recoup your investment.

Conclusion

Investing in a UV DTF printer can be a game-changer for your business, providing versatility, high-quality prints, and efficiency. By focusing on the essential features discussed in this guide – from print quality and speed to software compatibility – you can make an informed decision that meets your specific printing needs. Once you narrow down your options, consider testing the printers in a demo to see how they perform in real-world applications.

If you're ready to find a high-quality UV DTF printer that meets your needs, explore our high-quality UV-DTF printers here and take the first step towards enhancing your printing capabilities.

FAQ

1. What is a UV DTF printer?

A UV DTF printer is a type of printer that uses ultraviolet light to cure inks onto various surfaces. This technology provides vibrant colors and durable finishes, making it suitable for printing on materials like wood, metal, plastic, and more.

2. How does UV curing work?

UV curing involves the use of ultraviolet light to instantly dry and harden the ink as it is printed onto the substrate. This process eliminates drying time and provides a robust finish that is resistant to fading and damage.

3. Are UV inks environmentally friendly?

UV inks are generally considered to be more environmentally friendly than traditional solvent-based inks. They contain fewer volatile organic compounds (VOCs) and offer better durability, reducing waste over time.

4. Can I print on fabric using a UV DTF printer?

Yes, many UV DTF printers are capable of printing on fabric. However, it's essential to ensure that the printer is designed for textile printing and uses the appropriate inks for the best results.

5. What maintenance do UV DTF printers require?

Maintenance for UV DTF printers typically includes regular cleaning of print heads, checking ink levels, and replacing parts such as filters or nozzles when needed. Some models offer self-cleaning features to simplify the maintenance process.