Introduction

Introduction

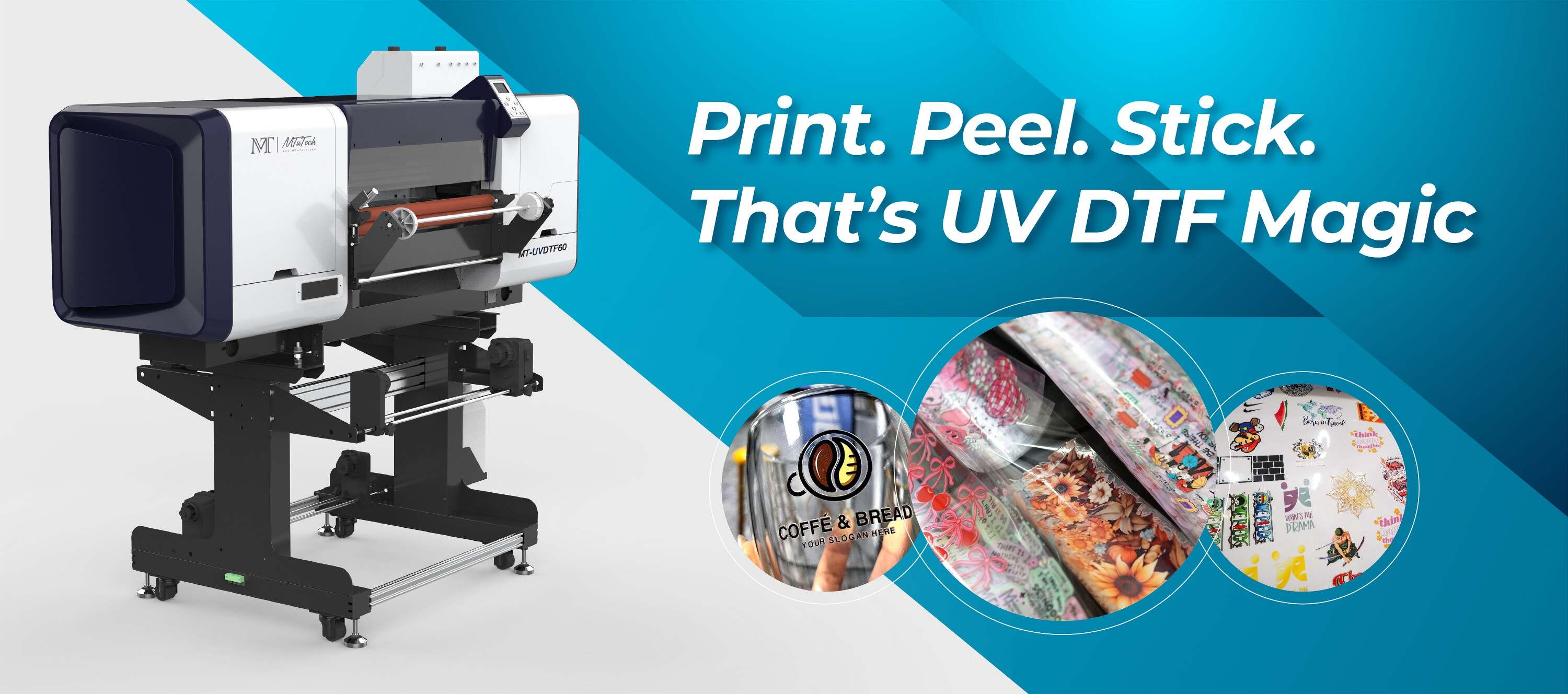

UV Direct-to-Film (DTF) printing has become a game changer in the world of digital printing, allowing businesses to produce vibrant designs on a wide range of materials. However, like any advanced machinery, UV DTF printers require regular maintenance to perform optimally. In this guide, we will explore essential maintenance procedures and helpful troubleshooting tips to keep your UV DTF printer running smoothly and efficiently.

Understanding Your UV DTF Printer

Before we dive into maintenance and troubleshooting, it's essential to understand the components of a UV DTF printer. This type of printer utilizes UV light to cure ink on the film, which is then transferred to various surfaces. The primary components include:

Print Head: Responsible for delivering the ink onto the film accurately.

UV Lamp: Cures the ink once it has been applied to the film.

Ink Supply System: Delivers inks to the print head in the correct quantities.

Control Panel: Allows users to adjust settings and monitor the printing process.

Mechanical Components: Includes the frame, rollers, and belts that help in the movement of the printing apparatus.

Routine Maintenance Procedures

Regular maintenance is essential for extending the lifespan of your UV DTF printer and ensuring high-quality output. Here are some critical maintenance procedures to follow:

Daily Maintenance

Clean the Printhead: Use a suitable cleaning solution and a lint-free cloth to wipe the printhead after each use. This prevents dried ink buildup.

Check Ink Levels: Monitor ink levels daily to avoid running out mid-job, which can cause print quality issues.

Inspect for Dust and Debris: Regularly check and clean the printer exterior and surrounding area to prevent dust from entering the machine.

Weekly Maintenance

Deep Cleaning: Perform a more thorough cleaning of the printhead and the ink lines using appropriate cleaning solutions.

Calibration: Run calibration tests to ensure that the printer outputs accurate colors and alignment.

Check for Mechanical Wear: Inspect belts and rollers for wear and replace them if necessary to prevent mechanical issues.

Monthly Maintenance

Firmware Updates: Check for any firmware updates from the manufacturer and apply them to ensure optimal performance.

Inspect UV Lamps: Examine and replace UV lamps as needed, as they lose effectiveness over time.

Full System Clean: Conduct a full cleaning of all internal parts using a vacuum and suitable cleaning agents to remove any accumulated ink particles.

Troubleshooting Common Issues

Even with regular maintenance, issues may arise from time to time. Here are some common problems users encounter with UV DTF printers and effective solutions:

Print Quality Issues

Blurry Images: Check alignment and calibrate the printer. Clean the print head and ensure that the ink cartridges are properly seated.

Inconsistent Colors: This can occur due to low or contaminated ink. Replace any faulty ink cartridges and perform color calibration.

Streaks and Lines: Clean the print head thoroughly and check for any obstructions in the ink supply lines.

Mechanical Problems

Printer Not Responding: Restart the printer and check connections. If the problem persists, investigate for firmware issues or hardware malfunctions.

Paper Jams: Carefully remove any jammed film and inspect the roller system for wear or obstructions.

Electrical Issues

Power Supply Problems: Check all power connections, ensure the circuit is functional, and inspect the power cord for damages.

UV Lamp Not Working: Inspect the UV lamp to see if it is properly seated; if not, reseat it. If it is unresponsive, it may be time to replace it.

Best Practices for Optimal Performance

In addition to routine maintenance and troubleshooting, adopting best practices can further enhance your UV DTF printer's performance:

Use Quality Materials: Always use high-quality inks and films designed for your specific printer model.

Keep Environment Clean: Maintain a clean workspace and control humidity and temperature levels to avoid issues related to moisture or dust.

Train Staff Effectively: Ensure that everyone operating the printer understands maintenance and troubleshooting protocols.

Conclusion

Maintaining your UV DTF printer is crucial for ensuring high-quality prints and prolonging the lifespan of your equipment. Adherence to regular maintenance schedules and being proactive in troubleshooting issues can save you time and resources in the long run. By implementing the tips and practices outlined in this guide, you'll be well-equipped to keep your UV DTF printer in top working condition. For more information and high-quality UV-DTF printers, explore our high-quality UV-DTF printers here.

FAQ

How often should I clean my UV DTF printer?

It's recommended to clean the print head daily, perform deep cleaning weekly, and conduct a full maintenance check monthly to keep the printer functioning at its best.

What should I do if my prints are blurry?

If prints appear blurry, check the alignment, perform a calibration, and clean the print head thoroughly to remove any dried ink or debris.

How can I prevent paper jams?

Regularly inspect and maintain the roller system, ensure that only compatible films are being used, and make sure the film is fed correctly into the printer.

What signs indicate that the UV lamps need replacing?

If you notice poor adhesion of ink to the film or the print quality has declined significantly, it may be time to inspect and replace the UV lamps.

Can I use any type of ink with my UV DTF printer?

No, it's essential to use high-quality inks specifically designed for your UV DTF printer to ensure proper function and optimal print quality.