Introduction

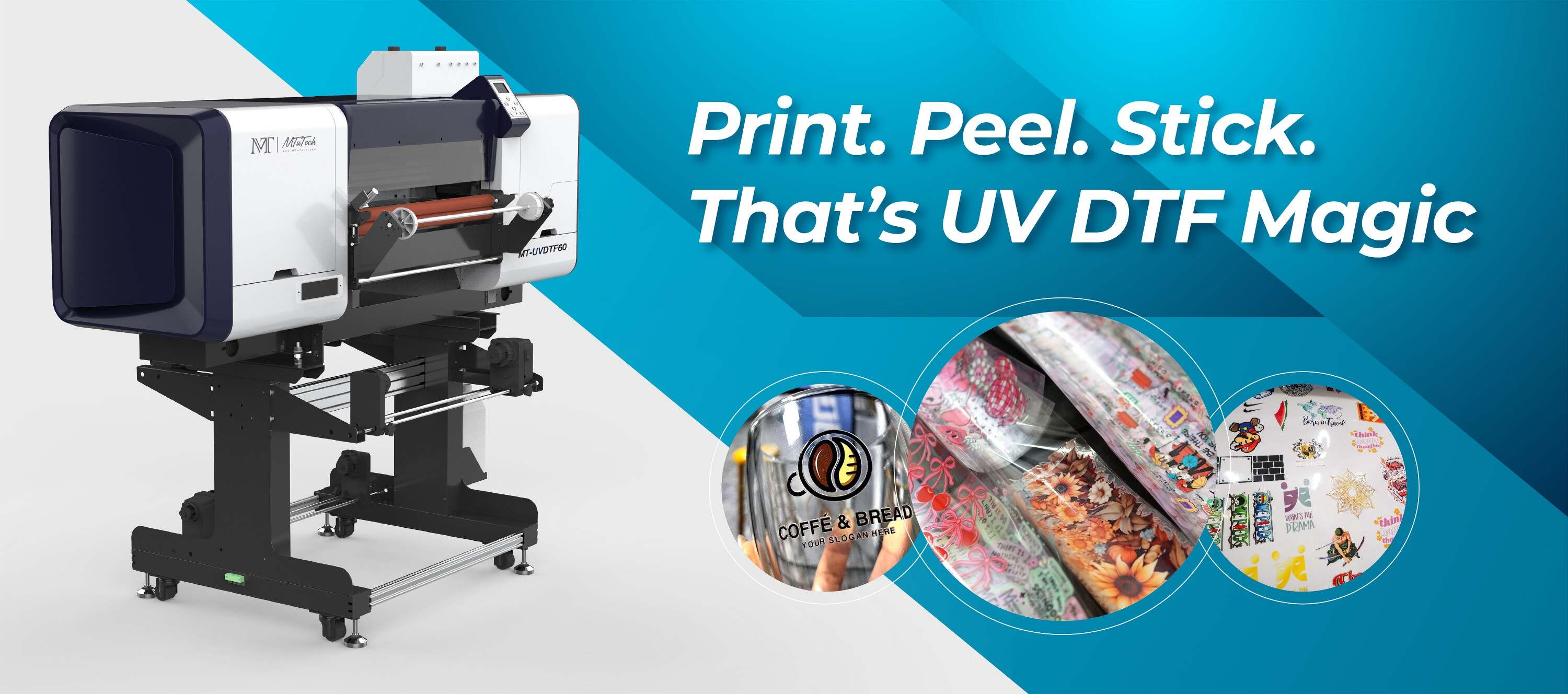

In the realm of customized promotional products and personalized sports gear, the demand for high-quality printing solutions is ever-increasing. Among the many printing technologies available today, UV Direct-to-Film (DTF) printing has emerged as a game-changer, especially for printing on materials like water bottles and sports gear. This blog will explore the advantages of using a UV DTF printer, the features that make it stand out, and how it can elevate your custom printing projects.

Benefits of Using a UV DTF Printer

UV DTF printing integrates precision, speed, and versatility. These printers are engineered to cater to various materials, making them an excellent investment for businesses looking to expand their service offerings. Here are some key benefits:

Exceptional Print Quality: UV DTF printers produce vibrant colors and sharp images, allowing for detailed designs on various surfaces.

Durability: The ink used in UV DTF printing is cured with UV light, resulting in prints that are resistant to scratches, fading, and water damage.

Wide Material Compatibility: These printers can print on a variety of surfaces including metals, plastics, glass, and textiles, making them perfect for custom water bottles and sports gear.

Environmentally Friendly: UV inks typically emit fewer volatile organic compounds (VOCs) compared to traditional inks, making them a more eco-friendly choice.

Quick Turnaround Time: The UV curing process allows for immediate handling post-printing, reducing delays in production and delivery.

Features of UV DTF Printers

When looking for the ideal UV DTF printer for your custom water bottle and sports gear projects, it’s essential to consider its features. Below are some noteworthy characteristics that set UV DTF printers apart:

1. High Resolution Printing

Most UV DTF printers offer high-resolution capabilities, typically ranging from 1200 dpi to 2400 dpi, which ensures that every detail of your design is accurately reproduced. This level of detail is crucial for creating intricate logos or designs that resonate with your brand's identity.

2. Multi-Layer Printing

Advanced UV DTF printers allow for multi-layer printing, enabling users to create textured effects or spot gloss finishes. This feature is particularly beneficial for sports gear, where visual appeal and durability are paramount.

3. Integrated UV Curing Technology

The integration of UV curing technology ensures that prints dry instantly, facilitating faster production timelines. With the ability to go from design to delivery in record time, businesses can meet tight deadlines without compromising quality.

4. User-Friendly Interface

Many modern UV DTF printers come with an intuitive user interface, making it easy for operators to navigate through the printing process, adjust settings, and monitor production. This usability reduces the learning curve for new staff and enhances operational efficiency.

5. Versatile Printing Sizes

UV DTF printers are available in various sizes, accommodating everything from smaller water bottles to larger sports gear. This flexibility allows businesses to cater to a broader range of customer requests.

Applications of UV DTF Printing in Custom Water Bottles and Sports Gear

The adaptability of UV DTF printers makes them suitable for various applications in custom water bottles and sports gear. Below are some popular uses:

Promotional Products: Businesses can create custom-branded water bottles and sports items as promotional giveaways, enhancing their marketing efforts.

Personalized Gifts: Custom water bottles with unique designs or personal messages make excellent gifts for events like marathons or corporate retreats.

Team Merchandise: Sports teams can use UV DTF printing to create custom jerseys, hats, and water bottles showcasing team colors and logos, fostering team spirit.

Fundraising Initiatives: Custom designed items can be sold to raise funds for schools, sports clubs, and charitable organizations.

Choosing the Right UV DTF Printer

When selecting a UV DTF printer, several factors should be taken into consideration to ensure it meets your specific needs:

1. Print Volume Requirements

Assess your print volume needs based on your business model. High-capacity printers may be necessary for businesses that receive large orders consistently.

2. Printing Speed

Different models have varying printing speeds. If quick turnaround times are vital for your business, choose a printer with faster production capabilities.

3. Customer Support and Warranty

Consider the manufacturer's customer support and warranty offerings. A printer backed by a reliable warranty and responsive support will minimize downtime.

4. Budget

Finally, set a budget and stick to it. Evaluate the initial cost against long-term benefits to determine the best value for your investment.

Conclusion

The versatility and efficiency of UV DTF printers position them as a top choice for custom printing needs, particularly in the growing market of personalized water bottles and sports gear. With their exceptional print quality, durability, and quick turnaround times, businesses can truly set themselves apart. Whether you’re a small startup or an established company looking to expand your offerings, investing in a UV DTF printer can be a fruitful decision. Explore our high-quality UV-DTF printers here and discover how they can elevate your custom printing projects to new heights.

FAQ

What materials can I print on with a UV DTF printer?

UV DTF printers can print on a wide range of materials, including plastics, metal, glass, and textiles, making them perfect for both promotional products and sports gear.

How durable are the prints from a UV DTF printer?

The prints produced by UV DTF printers are highly durable, resistant to fading, scratching, and water damage, ensuring that they maintain their quality over time.

Can I use a UV DTF printer for small-scale production?

Yes, UV DTF printers are suitable for both small-scale and large-scale production, making them versatile for businesses of all sizes. Adjust the settings and production volumes according to your business needs.

Are UV DTF printers environmentally friendly?

Compared to traditional printing methods, UV DTF printers emit fewer volatile organic compounds (VOCs), making them a more environmentally friendly option for custom printing.

What is the typical turnaround time for printing with a UV DTF printer?

One of the advantages of UV DTF printing is the rapid turnaround time. Because prints dry instantly due to UV curing, products can often be completed and shipped on the same day, depending on the volume.