Introduction

The custom printing industry is experiencing rapid growth, driven by the demand for personalized products, especially in the realms of sports gear and promotional items. One of the latest innovations in this space is the UV Direct-to-Film (DTF) printer. This technology is revolutionizing the way we create custom designs, transforming standard items like water bottles and sports apparel into unique, eye-catching products. In this blog post, we will explore how UV DTF printers work, their benefits, and features that make them an ideal choice for custom printing.

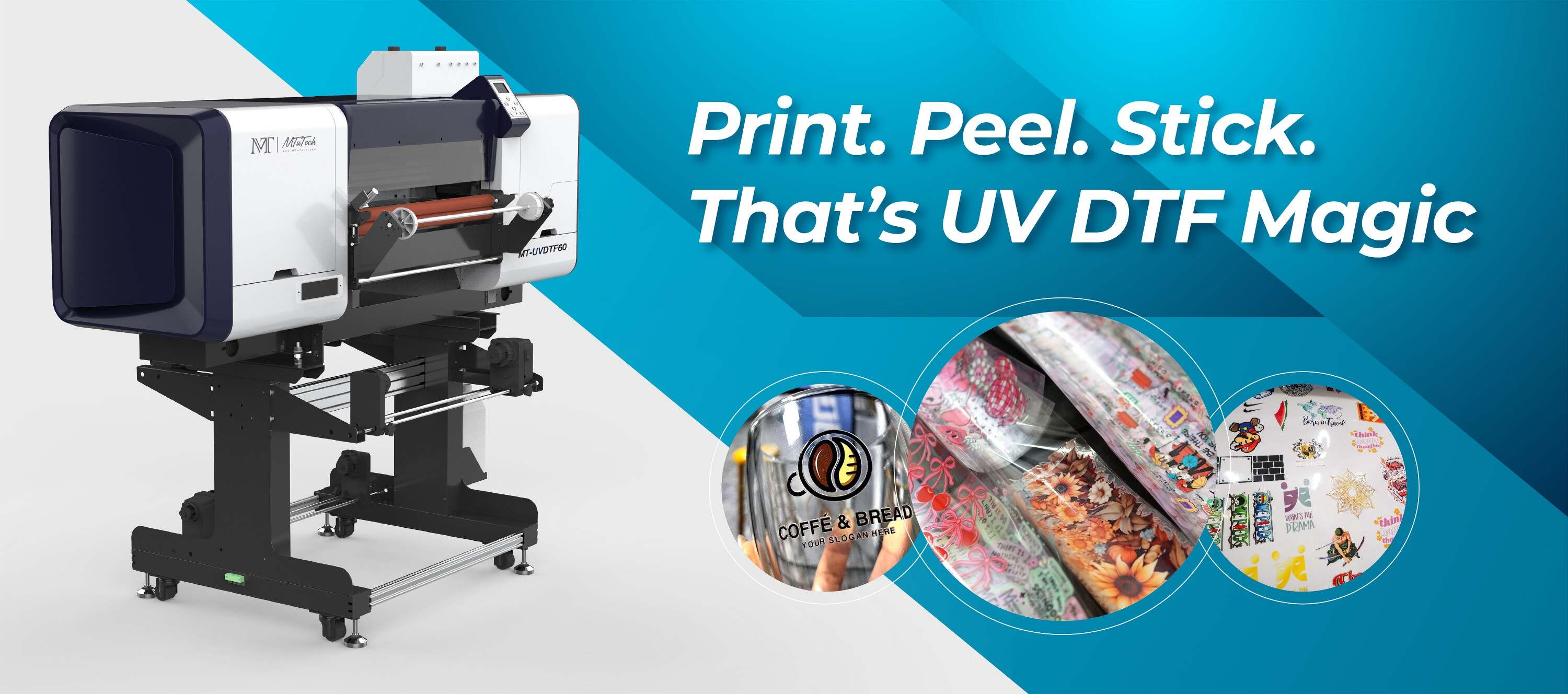

What is UV DTF Printing?

UV DTF printing is a technique that employs ultraviolet (UV) light to cure or dry inks printed onto a film. This process allows for the transfer of vibrant and durable designs onto various substrates, including plastic, metal, and glass, making it particularly suitable for products like water bottles and sports gear. Unlike traditional printing methods, UV DTF printing can produce high-quality images with intricate details, exceptional color vibrancy, and superior adhesion.

Benefits of Using UV DTF Printers

Many advantages come with using UV DTF printers for custom water bottle and sports gear printing. Here are some of the key benefits:

High-Quality Prints: UV DTF printers deliver sharp, vibrant images with excellent clarity, making them ideal for intricate designs and logos.

Versatility: They can print on a wide variety of materials, including plastic, glass, and metal, enabling creators to expand their product offerings.

Durability: The inks used in UV DTF printing are resistant to scratches, fading, and water, ensuring that custom designs last longer even under tough conditions.

Faster Production Speed: With the ability to print directly onto films and cure them instantly, the overall production time is significantly reduced.

Eco-Friendly Options: Many UV DTF printers utilize environmentally friendly inks, reducing the ecological impact of custom printing.

Features of UV DTF Printers

When considering a UV DTF printer for your custom printing needs, it's essential to look into some specific features that can enhance your printing experience:

1. Advanced Printhead Technology

Modern UV DTF printers come equipped with advanced printhead technology that allows for precise ink droplet placement, resulting in high-resolution prints. This precision enables complex designs to be reproduced with stunning detail.

2. Quick Curing Capability

UV DTF printers can instantly cure inks using UV light, which allows for efficient production workflow. This feature minimizes wait times and enhances the overall productivity of the printing process.

3. User-Friendly Interface

Many UV DTF printers now feature intuitive touch-screen interfaces that make it easier for users to operate the machine, adjust settings, and monitor print quality, regardless of their level of experience.

4. Multiple Ink Options

The best UV DTF printers support a variety of ink types, including flexible and ultra-high-gloss inks, allowing for different finishes and effects that can accommodate various design requirements.

5. Size and Scalability

UV DTF printers are available in various sizes to fit different business needs. Whether you are a small business owner or a larger enterprise, there are options to suit your specific production volume and space.

Applications of UV DTF Printing

The applications of UV DTF printing extend far beyond just water bottles and sports gear. Here are some other popular uses:

Promotional Products: Businesses can create customized promotional items such as mugs, bags, and gadgets that feature their logos and branding.

Home Decor: Items like custom tiles, photo frames, and decorative bottles are increasingly popular due to their unique designs.

Corporate Gifts: Customized gifts are an excellent way to engage clients and employees during corporate events or as part of branding strategies.

Jewelry and Accessories: UV DTF printers can be used to print intricate designs on various fashion accessories.

Getting Started with UV DTF Printing

If you're considering using UV DTF printing technology for your custom printing business, here are some steps to help you get started:

1. Choose the Right Printer

Do your research and choose a UV DTF printer that meets your specific needs. Consider factors like print quality, speed, size, and user-friendliness.

2. Invest in Quality Inks and Films

Always opt for high-quality inks that provide durability and vibrant colors. Make sure to use the right films that are compatible with your printer to achieve the best results.

3. Design Your Graphics

Use graphic design software to create or modify your designs before processing them for printing. Ensure your graphics are scalable and of high resolution to maintain print quality.

4. Test and Optimize

Before launching into full production, conduct test prints to fine-tune the settings and ensure that your output meets quality standards.

5. Market Your Products

Once you're ready, promote your custom printed products through various channels, such as social media, online marketplaces, and local events.

Conclusion

With growing demand for personalized products, investing in a UV DTF printer can provide you with a competitive edge in the custom printing market. The versatility, quality, and efficiency of UV DTF printers make them an excellent choice for creating stunning custom water bottles and sports gear. By understanding the technology and following best practices, you can ensure that your products stand out in a crowded marketplace. Ready to elevate your printing game? Explore our high-quality UV-DTF printers here and take the first step toward transforming your custom printing capabilities.

FAQ

What is the difference between UV DTF and traditional printing methods?

UV DTF printing utilizes ultraviolet light to cure inks on films, resulting in vibrant, durable designs. Traditional methods, like screen printing, often require more steps and may not produce the same level of detail or durability.

Can UV DTF printers print on all types of surfaces?

Yes, UV DTF printers can print on a wide array of surfaces, including plastic, metal, glass, and textiles, making them highly versatile for various applications.

How long do prints last when using UV DTF technology?

Prints created using UV DTF technology are highly durable, resistant to UV light, water, and scratches. When properly cared for, they can last for many years without fading.

Is it easy to operate a UV DTF printer?

Most modern UV DTF printers come with user-friendly interfaces, making them relatively easy to operate even for beginners, although some training may be needed to maximize their potential.

What types of inks can be used with a UV DTF printer?

UV DTF printers typically use UV-reactive inks, which are designed to cure quickly under UV light, ensuring superior adhesion and durability on multiple substrates.