Introduction

Decorating mugs and ceramic items has become a thrilling business venture and a hobby for many. With the rise of technology, particularly Digital Textile Printing (DTF) and Ultraviolet (UV) printing, creating stunning designs has never been easier. One of the most effective methods to achieve high-quality prints on mugs and ceramics is using a UV DTF printer. This guide will walk you through the benefits, features, and step-by-step procedures for using a UV DTF printer effectively.

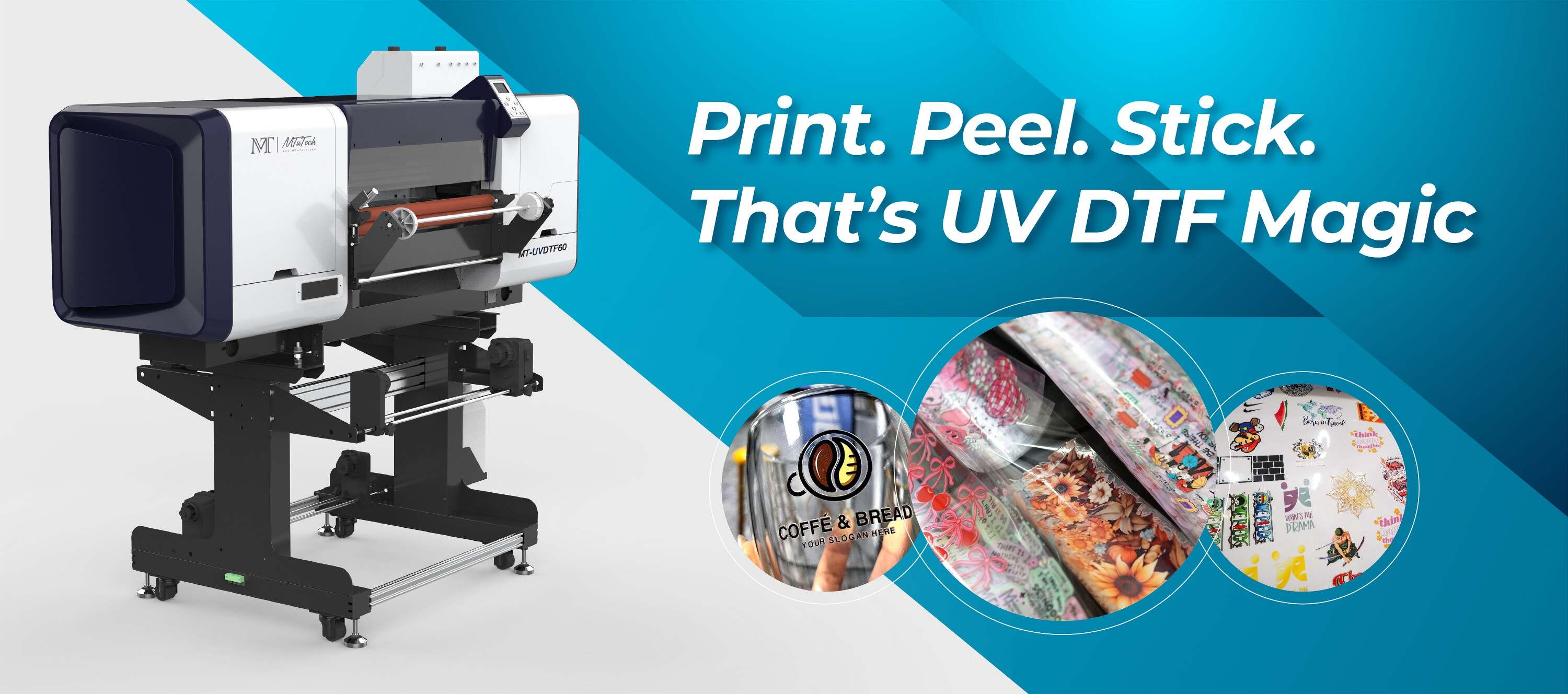

What is a UV DTF Printer?

A UV DTF printer combines the capabilities of UV printing and direct-to-film technology. It allows for vibrant color reproduction, excellent durability, and the ability to print on a variety of surfaces, including mugs and ceramics. The printer uses UV light to cure the ink as it is printed, ensuring that the designs adhere robustly to the surfaces.

Benefits of Using a UV DTF Printer

Employing a UV DTF printer for your mug and ceramic printing projects comes with numerous advantages:

Versatility: Capable of printing on various materials beyond ceramics.

Durability: UV-cured inks are resistant to scratches, abrasions, and UV light.

Vibrant Colors: Produces rich, vivid colors that stand out.

Environmental Safety: UV inks are typically low in volatile organic compounds (VOCs).

Cost-effective: Minimizes material waste with precise printing techniques.

Features to Look For in a UV DTF Printer

When selecting a UV DTF printer, consider these essential features:

Print Width: Ensure the printer can accommodate the size of the mugs or ceramics you intend to print on.

Print Resolution: Look for high DPI capabilities for sharp and clear images.

Ink Types: Some printers use special inks that offer better adhesion and color vibrancy.

Ease of Use: A user-friendly interface can drastically reduce the learning curve.

Support and Repairs: Check for manufacturer support and warranty options.

Step-by-Step Guide to Using a UV DTF Printer for Mugs and Ceramics

Step 1: Gather Your Materials

Before you start printing, ensure you have all the necessary materials:

UV DTF printer

Special UV DTF ink

Mugs or ceramic items to be printed

Transfer film

Heat press machine (if required)

Design software

Protective gloves and eyewear

Step 2: Design Your Artwork

Using design software, create or alter your artwork to fit the dimensions of the print area on your mugs or ceramics. Make sure to:

Use high-resolution images (300 DPI recommended)

Convert all text to outlines or rasterize layers

Consider the color profiles suitable for UV printing

Step 3: Prepare the UV DTF Printer

Set up your UV DTF printer by following these steps:

Ensure it is plugged in and powered on.

Load the UV DTF ink cartridges according to the manufacturer's instructions.

Calibrate the printer to adjust for the thickness of the transfer film if required.

Load your transfer film into the printer.

Step 4: Print the Design

Once your design is ready and the printer is prepared:

Send the design to the printer via your connected device.

Monitor the printing process to ensure everything is functioning correctly.

Once printed, allow the ink to cure under the UV light (most printers have this feature built-in).

Step 5: Transfer Print to Ceramic Mug

After the print cures on the transfer film, it’s time to transfer the image to your ceramic mug:

Position the print on the mug’s surface.

If using a heat press, set it to the appropriate temperature and pressure.

Apply the transfer film to the mug, ensuring it's secured.

Press and hold for the required time as per your printer’s guidelines.

Step 6: Finishing Touches

After pressing, carefully peel the transfer film away. Inspect your printed mug or ceramic item for quality, ensuring there are no smudges, misalignments, or defects. If everything looks good:

Allow the item to cool completely.

Store or present your printed mug professionally.

Maintenance Tips for Your UV DTF Printer

To ensure the longevity of your printer and maintain print quality, consider these maintenance tips:

Regularly clean print heads and nozzles to prevent clogs.

Check and replace ink cartridges periodically.

Keep the printer in a dust-free environment.

Update software and firmware when necessary for optimal performance.

Conclusion

Using a UV DTF printer for mugs and ceramics opens up a world of possibilities for custom designs, whether for personal use or business ventures. With this step-by-step guide, you can easily achieve vibrant, durable prints that stand the test of time. Consider acquiring a UV DTF printer to enhance your creative projects and elevate your product offerings. If you are in search of high-quality UV DTF printers, explore our high-quality UV-DTF printers here.

FAQ

What materials can I print on using a UV DTF printer?

UV DTF printers can print on a wide range of materials including ceramics, textiles, wood, metal, plastic, and more, making them highly versatile for various projects.

What is the difference between UV DTF and traditional printing methods?

Unlike traditional printing, UV DTF printing cures the ink instantly with UV light, allowing for immediate handling of the printed items. This method often results in more vibrant colors and durable prints.

How do I care for printed mugs and ceramics?

Printed mugs and ceramics should be hand washed with mild soap and water. Avoid abrasive tools to prevent scratching the print, and do not use the dishwasher to maintain the integrity of the design.

Can I use a UV DTF printer for large production runs?

Yes, UV DTF printers are capable of handling large production runs efficiently. They provide high-speed printing capabilities without compromising print quality, making them suitable for bulk orders.

Is it necessary to use special ink for UV DTF printers?

Yes, UV DTF printers typically require specialized UV inks that are formulated for direct printing and curing under UV light. Using the correct ink ensures optimal adhesion and durability on the printed surface.