Introduction

Introduction

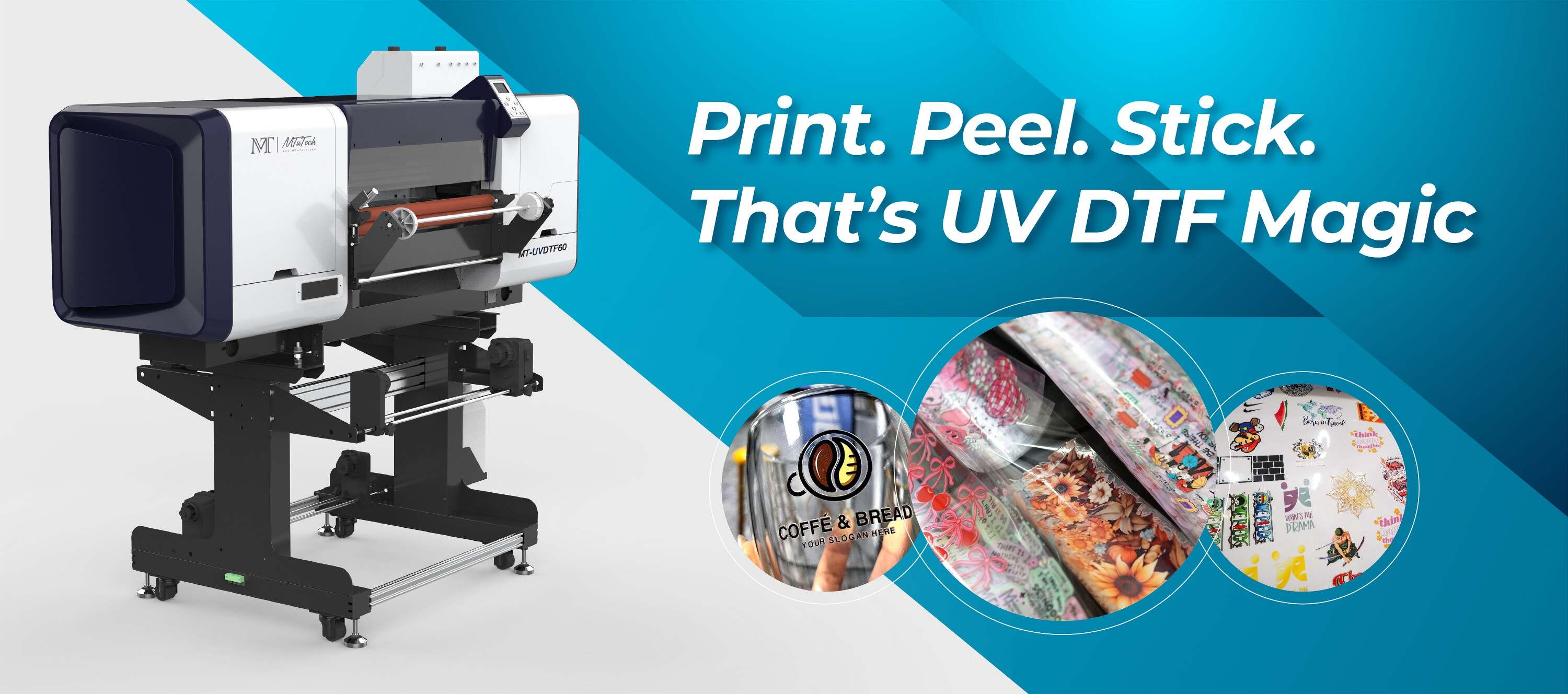

As the demand for personalized tech accessories grows, UV DTF printing is becoming the go-to method for custom branding on electronics and gadgets. From smartphone cases to power banks and headphones, this technique offers unmatched versatility and vibrant results. In this guide, we’ll explore how UV DTF is transforming electronics customization.

Why UV DTF is Perfect for Gadgets

- No Heat Required: Won’t damage delicate electronics

- High Resolution: Captures fine details and brand elements

- Strong Adhesion: Bonds to smooth plastic, metal, or polycarbonate surfaces

- Durable: Scratch-resistant and water-resistant for everyday use

Top Electronics to Customize with UV DTF

- Phone cases (plastic, silicone, leather)

- Wireless earbuds and charging cases

- Laptop covers and touchpads

- Power banks and chargers

- Game controllers and remotes

- Bluetooth speakers and accessories

Tips for Printing on Electronics

- Surface Prep: Always clean with alcohol to remove oils

- Flat Surface Areas: Focus on areas without curves or seams

- Design Size: Scale to fit and avoid ports or buttons

- Cure Time: Let transfers bond for 12–24 hours before use

Custom Tech Merch Opportunities

- Branded corporate giveaways

- Personalized gifts and packaging

- Limited-edition collaborations for influencers and events

- Small-batch production for gadget brands or e-tailers

Precautions to Consider

- Avoid applying decals on active heat zones or vents

- Test compatibility on cheaper or unused devices before customer use

- Some soft-touch plastics may resist adhesion — always test

Conclusion

UV DTF printing opens up a world of possibilities for tech-savvy creators and gadget brands. With proper prep and the right materials, you can deliver sharp, durable designs that elevate the look and feel of any electronic product.

Create custom gadget gear with our advanced UV DTF printer — optimized for crisp prints on electronics and tech accessories.