Introduction

UV printing has revolutionized the way businesses approach printing, offering unparalleled quality and versatility. Unlike traditional printing methods, UV printing utilizes ultraviolet light to dry and cure inks instantly upon application. This technology allows for a wide range of materials and applications, making it a popular choice for businesses looking to enhance their product offerings. In this blog post, we'll delve into the workflow of a UV printing business, exploring each step from preparation to the final product.

Understanding the UV Printing Process

The workflow of a UV printing business can be segmented into several key stages:

1. Pre-Press Preparation

The journey begins with pre-press preparation, which involves several critical steps:

Design Creation: Graphic designers create digital files that will be printed. This involves selecting images, layouts, and text to ensure that everything aligns with the client's vision.

File Formatting: Files are formatted according to the printer specifications. This may include setting the correct color modes, resolutions, and bleed areas to ensure a flawless print.

Proofing: A digital proof is often shared with the client for approval. This step is crucial to avoid costly mistakes in the final product.

2. Material Selection

Choosing the right substrate is essential in UV printing. The materials that can be used are diverse and include:

Plastic (Acrylic, PVC)

Metal

Wood

Glass

Paper and cardboard

Each material comes with its own unique properties and printing requirements, which can affect the choice of ink and printer settings.

3. Printing Setup

Now that the design is ready and the materials are chosen, it's time to set up the UV printer:

Printer Configuration: The printer is calibrated to ensure that ink flow, UV light intensity, and curing conditions are optimized for the selected substrate.

Ink Selection: UV inks come in various formulations and must be chosen based on the substrate material and the desired finish, whether matte or glossy.

Proofing Test Runs: Some businesses perform test runs to ensure the settings yield the desired quality before moving on to the final print run.

4. Printing Execution

This is where the magic happens. The actual printing process involves the following steps:

Layering: Unlike traditional printing methods, UV printing allows for stacking of layers, which can add texture and depth to the printed piece.

Curing Process: As the ink is applied, UV lights immediately cure and dry it, enabling vibrant colors and sharp details.

Quality Control: After printing, undergo a thorough inspection to ensure that the print meets quality standards. Any defects must be addressed before moving on to the finishing stage.

5. Post-Production and Finishing

Once the printing is completed, the next stage involves post-production, which may include:

Cutting and Trimming: Printed materials may need to be cut down to size. Precision is key to ensuring that the final product matches the design specifications.

Laminate or Coating: Adding a laminate or coating can enhance durability and aesthetics, protecting the print from scratches and UV damage.

Assembly: This might involve assembling multiple printed pieces or incorporating additional materials for a final product.

6. Packaging and Delivery

The final step in the workflow is packaging and delivery. This includes:

Safe Packaging: Ensuring that the printed materials are packaged securely to prevent damage during transport.

Shipping Logistics: Arranging for timely delivery to the client, while considering shipping options and costs.

Effective communication with clients during this phase is crucial to ensure satisfaction with the end product.

Benefits of UV Printing

UV printing comes with several distinct advantages that can set a business apart in a competitive market:

Speed: The immediate curing of UV inks allows for quicker turnaround times, making it ideal for businesses with tight deadlines.

Quality: UV printing produces vivid colors and sharp images, enhancing the overall quality of the printed product.

Sustainability: UV inks are often more environmentally friendly compared to traditional inks, as they emit fewer volatile organic compounds (VOCs) during the curing process.

Versatility: The ability to print on various substrates opens up numerous possibilities for creative applications.

Challenges in UV Printing

While UV printing has many benefits, there are also challenges that businesses may face, such as:

Equipment Costs: The initial investment for high-quality UV printers can be significant.

Material Limitations: Not all materials are suitable for UV printing, which can limit options based on client needs.

Technical Skills: Staff must be trained adequately to operate the machines and manage the printing process effectively.

Conclusion

Starting and managing a UV printing business requires a comprehensive understanding of the workflow involved. Each stage—from pre-press preparation to packaging—plays a vital role in delivering high-quality printed products that meet customer expectations. By mastering each step and staying abreast of industry advancements, a UV printing business can thrive in today's dynamic market.

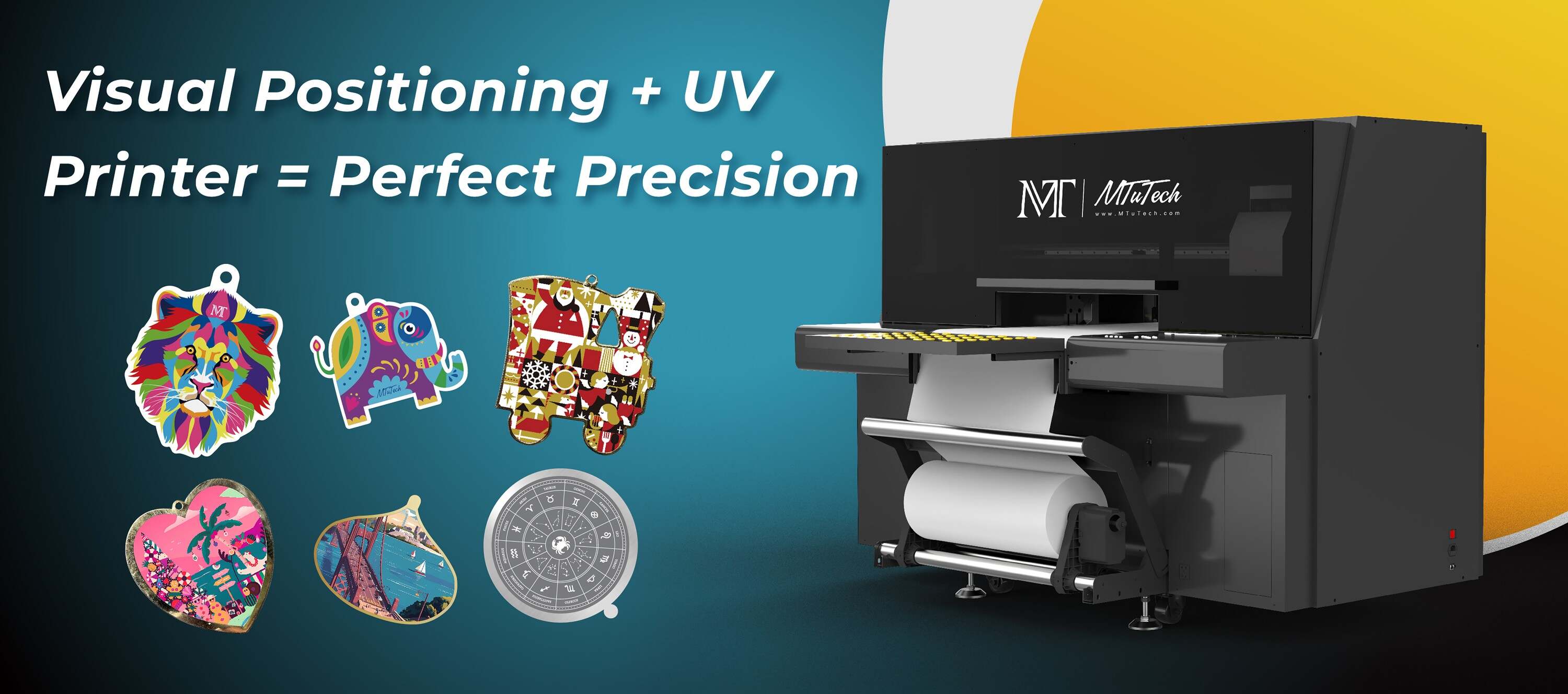

For those exploring or expanding their UV printing capabilities, investing in high-quality equipment is essential. Explore our high-quality UV printers here to find the perfect fit for your business needs.

FAQ

What is UV printing?

UV printing is a digital printing technology that utilizes ultraviolet light to instantly cure inks as they are printed. This method offers high-quality output on a variety of substrates and is known for its vibrant colors and durability.

What are the primary applications of UV printing?

UV printing is versatile and can be used for a wide range of applications, including signs, displays, packaging, promotional materials, and custom products like personalized gifts or branded merchandise.

How does UV printing compare to traditional printing methods?

UV printing offers several advantages over traditional printing, including faster drying times, the ability to print on various substrates, and higher quality finishes. However, traditional methods may have lower initial equipment costs.

What substrates can be used in UV printing?

UV printing can be applied to numerous substrates, including plastics, metal, wood, glass, and various types of paper. The choice of substrate can influence the ink type and settings used during the printing process.

Is UV printing environmentally friendly?

Yes, UV printing is considered more environmentally friendly than traditional processes because it emits lower levels of volatile organic compounds (VOCs) during manufacturing and curing, making it a more sustainable option.