Best Lighting Angles for Optimal Visual Tracking in UV Printing

Introduction

In the fast-evolving world of UV printing, precision is key. Visual tracking plays a crucial role in ensuring that printed designs align accurately, especially in multi-layer or complex color applications. One critical factor that can significantly enhance visual tracking accuracy is lighting—specifically, the angles at which light is positioned during the printing process. This blog post will explore the best lighting angles for optimal visual tracking in UV printing, ensuring that your prints not only look great but are also produced with high efficiency and accuracy.

Understanding UV Printing

UV printing is a modern printing technology that uses ultraviolet light to cure or dry the ink as it is printed. This method allows for vibrant colors and a wide range of materials, making it ideal for various applications. However, the effectiveness of UV printing is not solely determined by the equipment and material used; the conditions under which printing occurs are equally important.

The Importance of Visual Tracking

Visual tracking refers to the ability of the printer to follow the design accurately as it prints. Misalignment can lead to color mismatches, overlapping designs, or other quality issues. Optimal visual tracking ensures that every layer of ink is applied correctly, resulting in flawless prints. Proper lighting angles are a key component of this process.

Benefits of Proper Lighting Angles

Implementing the right lighting angles can offer numerous benefits in the UV printing process. Here are some key advantages:

·

Enhanced Visual Clarity: Proper lighting can help operators see finer details and color distinctions, making it easier to spot any discrepancies.

·

·

Improved Alignment: Clear visibility makes it easier to align the printed material accurately with the design, ensuring higher precision.

·

·

Reduced Errors: Good lighting minimizes the chance of human error during the setup and monitoring processes.

·

·

Higher Efficiency: Effective visual tracking allows for a smoother workflow, increasing overall productivity.

·

Best Lighting Angles for Visual Tracking

Different lighting angles can impact how the printer captures and reflects the design details. Here are some recommended angles and setups:

1. Overhead Lighting

Overhead lighting is often the most common setup in print environments. Here’s how it can be beneficial:

·

Direct View: This angle offers an unobstructed view of the print surface, allowing for better tracking of designs.

·

·

Even Light Distribution: When lights are evenly distributed across the overhead plane, it helps in avoiding shadows, making every detail visible.

·

2. Side Lighting

Side lighting can highlight textures and nuances that overhead lighting might miss. Consider these features:

·

Shadow Creation: By casting shadows, side lighting can reveal misalignments and imperfections that need correction.

·

·

Texture Visibility: This angle aids in showcasing the texture of printed materials, which is crucial for high-quality output in some applications.

·

3. Back Lighting

Back lighting can sometimes be overlooked but can be very effective in certain setups:

·

Contrast Enhancement: Backlighting can enhance the contrast between colors, making it easier to spot errors.

·

·

Silhouette Effect: This angle helps operators see the outlines of their prints, aiding in alignment adjustments.

·

4. Adjustable Angle Lighting

Incorporating adjustable angle lighting systems allows for greater flexibility and optimization:

·

Customizability: Operators can adjust the angle of the lights based on the specific print job.

·

·

Adaptive Use: This system can cater to different materials and print complexities, ensuring that regardless of the project, the optimal lighting conditions are met.

·

Factors to Consider When Setting Up Lighting

Setting up the right lighting angles is not solely about the angles themselves; several considerations must be taken into account:

1. Light Quality

Fluorescent lights may create flickering or unnatural color reproduction, while LED lights tend to offer more consistent and flattering lighting. Always ensure that the light quality enhances the visibility of details without altering colors.

2. Light Intensity

Proper intensity is crucial as too much light can cause glare while too little can obstruct detail visibility. Use dimmers or filters to manage the light intensity effectively.

3. Reflections and Glare

Pay attention to the surfaces of the materials being printed. Glossy surfaces may reflect light in ways that obscure visibility. Adjust angles accordingly to minimize glare.

4. Environment Control

The environment in which printing takes place can greatly influence lighting conditions. Be aware of external light sources that can affect your setup and take steps to control them.

Conclusion

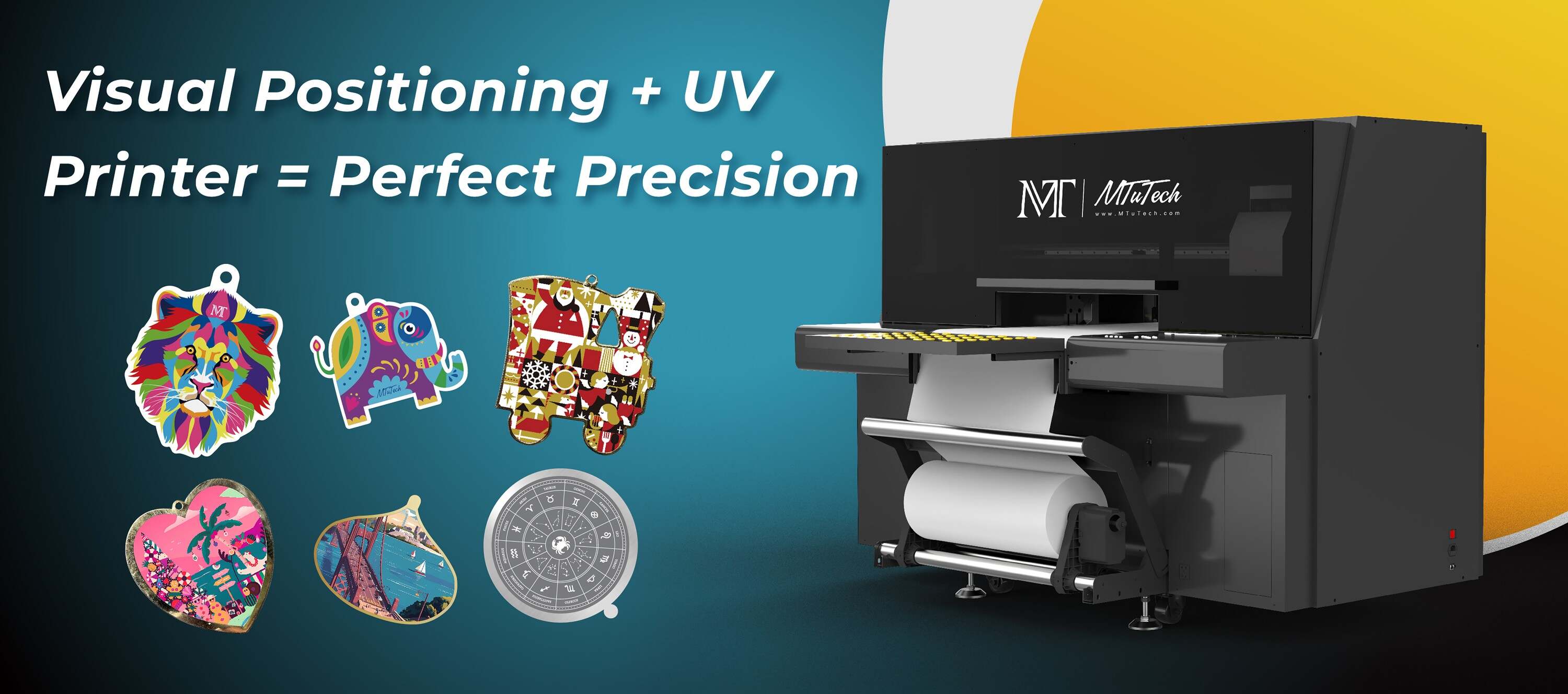

Optimal lighting angles are essential for achieving the highest quality in UV printing. By carefully selecting lighting setups and understanding their impact on visual tracking, operators can enhance accuracy, reduce errors, and ultimately craft exemplary prints. Whether you are a seasoned printing professional or just starting, investing time in experimenting with different lighting angles will inevitably yield better results. For those looking to enhance their UV printing capabilities, explore our high-quality Visual Positioning UV printers here.

FAQ

What type of lighting is best for UV printing?

The best type of lighting for UV printing is LED lighting because it provides consistent illumination without flickering, allowing for better visibility of details.

How do lighting angles affect the UV printing process?

Lighting angles impact the visibility of colors, textures, and potential misalignments, which are crucial for ensuring accurate visual tracking during the printing process.

Can I use natural light for UV printing?

While natural light can be beneficial in some settings, it is often inconsistent and can change throughout the day, potentially affecting visual tracking. It’s preferable to use controlled artificial lighting.

Is it necessary to invest in adjustable lighting?

Investing in adjustable lighting can enhance flexibility and efficiency, allowing operators to adapt the lighting setup based on specific print requirements.

What should I do if I notice glare during printing?

If glare occurs during printing, adjusting the angle of the lights or switching to a different light source can help minimize the issue. Additionally, reducing ambient light and using diffusers can be beneficial.