Choosing the Right Visual Calibration Kit for UV Printers

Introduction

In the realm of digital printing, particularly with UV printers, achieving precise colors and consistent quality is paramount. A vital tool for ensuring this consistency is the visual calibration kit. Selecting the right calibration kit can greatly influence the performance of your UV printer, affecting everything from image quality to production times. This blog will guide you through understanding the significance of visual calibration kits and how to choose the perfect one for your needs.

Understanding Visual Calibration Kits

What Is a Visual Calibration Kit?

A visual calibration kit is a collection of tools designed to ensure accurate color reproduction and alignment in UV printing processes. These kits typically include charts, targets, and measurement devices that help align color output to desired specifications.

Why Is Calibration Important?

Calibration is crucial for multiple reasons:

·

Color Accuracy: It ensures that colors being printed match the intended design.

·

·

Print Consistency: Regular calibration minimizes variations in color output between prints.

·

·

Increased Efficiency: Reduces the need for reprints due to color errors, saving time and resources.

·

Benefits of Using a Visual Calibration Kit

Enhanced Color Management

Visual calibration kits provide tools that assist in achieving accurate color management. With a calibrated printer, designers and print operators can be confident that the colors they see on screen will translate accurately to the printed material.

Improved Quality Control

Using a calibration kit allows for better quality control practices. By regularly calibrating your UV printer, you can catch any discrepancies early, preventing potential issues in large batch prints.

Cost Savings

Investing in a quality visual calibration kit can save money in the long run. Fewer reprints and wasted materials translate to lower operational costs. Additionally, consistent quality can boost customer satisfaction, leading to repeat business.

Key Features to Look for in a Calibration Kit

Compatibility with Your Printer

Before purchasing a visual calibration kit, ensure that it is compatible with your specific UV printer model. Kits are often designed for particular printer brands or series, so confirm compatibility to avoid unnecessary issues.

Ease of Use

Consider kits that are user-friendly, especially if your team may not have extensive training in color management. Kits that come with clear instructions or are designed for quick setup can save time and reduce the potential for errors.

Comprehensive Tools

A good calibration kit should include a variety of tools:

·

Color Targets: Essential for measuring color accuracy and aiding in visual assessments.

·

·

Measuring Instruments: Devices like densitometers or spectrophotometers for precise color measurements.

·

·

Reference Charts: Useful for comparing actual print output against industry standards.

·

Update Frequency

Calibration kits should be updated frequently, so ensure that the brand supports ongoing development and provides current software or tools to keep your kit relevant with industry standards.

Steps for Effective Calibration

Preparation

Before you begin the calibration process, make sure you have the following in place:

·

A clean workspace free of dust and contaminants.

·

·

Proper lighting conditions to assess color accuracy effectively.

·

·

The appropriate media that will be used in production.

·

Calibration Process

The calibration process can vary slightly depending on the kit and printer, but generally includes these steps:

1.

Set up your printer and ensure it is warmed up and ready.

2.

3.

Place the calibration target on the print bed as per the manufacturer’s instructions.

4.

5.

Print the calibration target and allow it to dry completely.

6.

7.

Use the measuring instrument to assess the printed colors against the target specifications.

8.

9.

Adjust the printer settings based on the readings to match your desired output.

10.

Regular Maintenance

To ensure ongoing accuracy, it's crucial to maintain a schedule for regular calibration, especially if your printer experiences significant use or if you change inks or media types often.

Conclusion

Choosing the right visual calibration kit for your UV printer is a critical investment in the success of your printing business. By understanding the benefits and features to look for, you can enhance your print quality, improve operational efficiency, and ultimately achieve greater customer satisfaction. Don’t overlook the power of a well-calibrated printer—take the time to research, select, and implement the right kit for your needs.

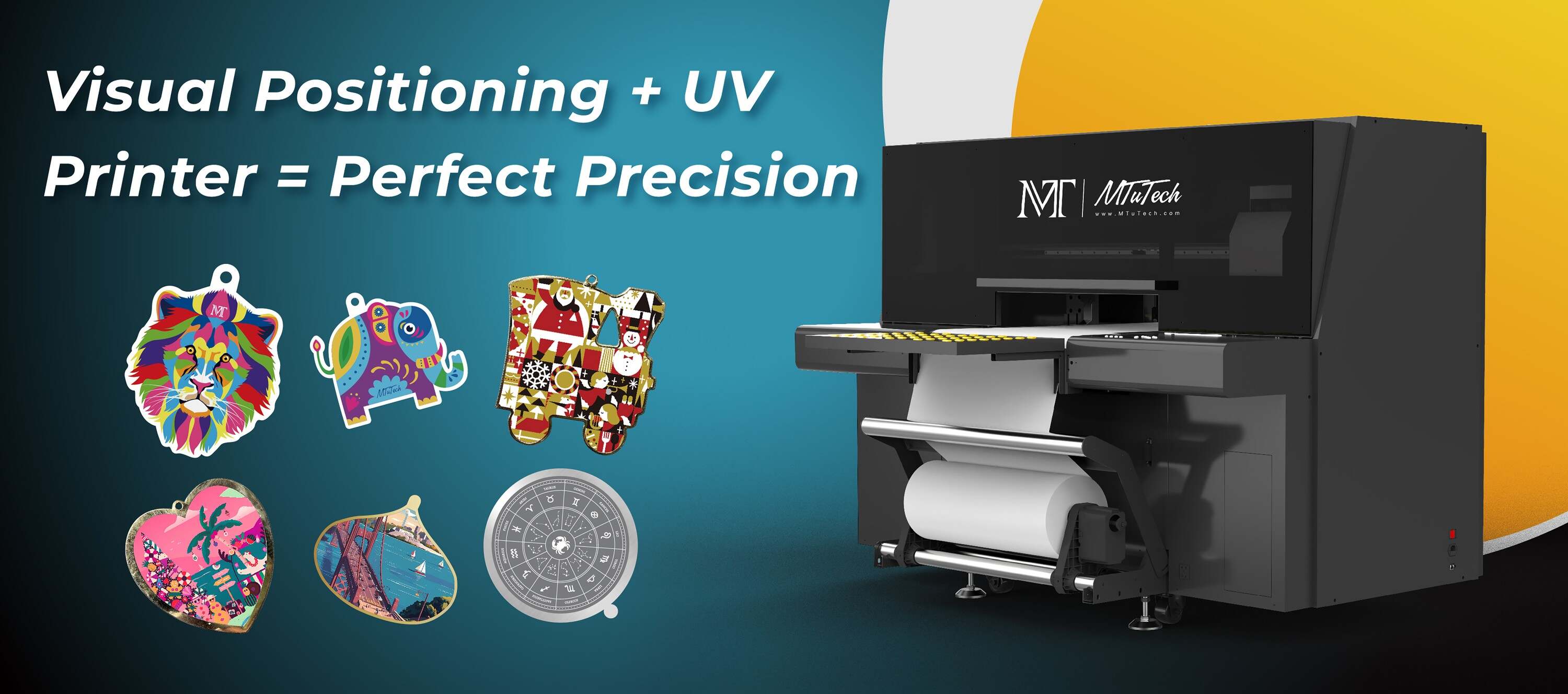

To explore options for visual calibration kits and enhance your UV printing capabilities, explore our high-quality Visual Positioning UV printers here.

FAQ

What types of visual calibration kits are available for UV printers?

There are various types of calibration kits available, including those for specific printer brands, multifunctional kits that cover multiple printers, and advanced kits that include sophisticated measurement tools like spectrophotometers.

How often should I calibrate my UV printer?

Calibration schedules can vary, but it is generally recommended to calibrate whenever there is a significant change in materials (inks or media), after maintenance, or weekly/monthly depending on usage volume.

Can I calibrate my printer without a professional?

Yes, many calibration kits are designed for users without extensive training. However, understanding color management basics will enhance your calibration proficiency. Following the manufacturer’s instructions is essential.

What can affect the accuracy of my UV printer's calibration?

Several factors can affect calibration accuracy, including changes in temperature and humidity, dirty print heads, old inks, or the use of different media types. Regular maintenance and calibration will help mitigate these issues.

Are visual calibration kits worth the investment?

Absolutely. The cost savings from reduced reprints, improved print quality, and enhanced customer satisfaction significantly outweigh the initial investment in a calibration kit. It's an essential tool for any serious printing operation.