How Visual UV Printers Achieve Edge-to-Edge Registration

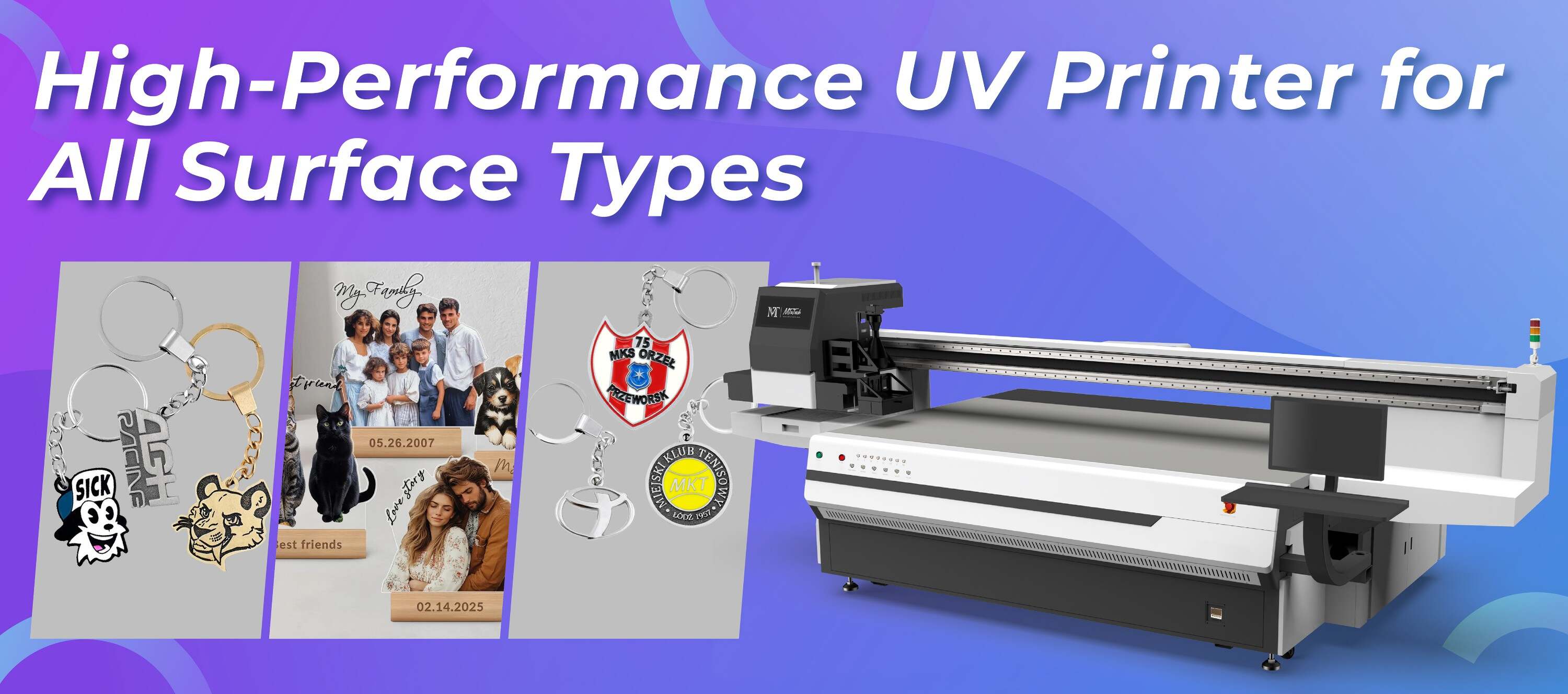

Introduction

In the world of printing technology, precision and accuracy are paramount, especially for businesses that require high-quality outputs. One of the most impressive advancements in this field is the development of Visual UV printers, which are designed to achieve exceptional edge-to-edge registration. This capability not only enhances the aesthetic appeal of printed products but also significantly improves efficiency. In this article, we will explore how Visual UV printers achieve this remarkable feat, the technology behind them, and their application in various industries.

The Basics of Edge-to-Edge Registration

Edge-to-edge registration refers to the precise alignment of printed images from one edge of the substrate to the other, leaving no margins or white spaces. This level of accuracy is essential for creating professional-quality prints for applications such as packaging, signage, and promotional materials. Maintaining consistent registration across multiple prints is critical for brand identity and overall product quality.

Importance of Edge-to-Edge Registration

Achieving edge-to-edge registration can have several advantages, including:

Professional Appearance: Prints that achieve this registration look polished and well-crafted, enhancing brand perception.

Reduced Waste: Precise registration reduces the likelihood of misprints, saving time and materials.

Versatility: Edge-to-edge printing accommodates various substrates, expanding creative possibilities.

How Visual UV Printers Work

Visual UV printers utilize cutting-edge technology to deliver exceptional quality and precision. Understanding how they operate can shed light on their ability to achieve edge-to-edge registration.

Visual Positioning Technology

The key feature of Visual UV printers is their unique visual positioning technology. This system uses advanced optical sensors and imaging systems to monitor and adjust the printing process in real time. Here’s how it works:

Optical Sensors: These sensors detect the position of the substrate as it moves through the printer, ensuring that the print head aligns perfectly for each pass.

Real-Time Adjustments: The system makes instantaneous adjustments to account for any discrepancies or movements, ensuring accurate placement of the UV ink.

High-Resolution Imaging: With high-resolution capabilities, the printer can deliver detailed images without compromising on alignment.

Inkjet Technology and UV Curing

Visual UV printers use inkjet technology combined with UV curing. Unlike traditional printing methods, which often require drying time, UV printing cures the ink instantly with ultraviolet light. This leads to:

Fast Turnaround: Because the ink is cured as it is laid down, prints can be completed rapidly.

Durability: UV-cured inks are resistant to scratches, fading, and water, making them ideal for various applications.

Features of Visual UV Printers That Enhance Registration

Several key features of Visual UV printers contribute to their ability to achieve edge-to-edge registration. Understanding these features can provide insights into their superior performance.

Precision Print Heads

The print heads in Visual UV printers are engineered for precision. They work in conjunction with the visual positioning system to maintain alignment and ensure consistent ink application across the entire substrate.

Advanced Software Solutions

These printers are equipped with sophisticated software that controls the printing process. This software assists in:

Calibration: Regular calibration ensures that the printer maintains its precision over time.

Design Adjustment: The software can adapt designs to accommodate any irregularities in the substrate, ensuring a perfect fit from edge to edge.

Stability and Consistency

To achieve effective edge-to-edge registration, the substrate must remain stable during the printing process. Visual UV printers are designed with robust feeding systems that ensure consistent movement and placement, further enhancing the accuracy of printing.

Applications of Visual UV Printers

The capabilities of Visual UV printers make them suitable for a wide range of applications, including:

Packaging Printing

In the packaging industry, edge-to-edge registration is crucial for creating eye-catching designs that attract customers. Visual UV printers allow for high-quality packaging solutions with vibrant colors and no unsightly margins.

Signage Production

For signs and banners, achieving accurate edge-to-edge prints can mean the difference between effective communication and misunderstandings. Visual UV printers excel in producing durable signage that requires minimal maintenance.

Promotional Materials

Business cards, brochures, and other promotional materials benefit from the sharp quality and vibrant colors produced by Visual UV printers. The ability to print edge-to-edge allows businesses to maximize the visual impact of their materials.

Conclusion

Visual UV printers represent a significant advancement in printing technology, offering unparalleled edge-to-edge registration capabilities. By harnessing visual positioning technology and UV curing, these printers deliver superior quality and efficiency across various applications. For businesses looking to enhance their printing capabilities, investing in a Visual UV printer can be a game-changer. Explore our high-quality Visual Positioning UV printers here and take your printing to the next level.

FAQ

What is edge-to-edge registration, and why is it important?

Edge-to-edge registration refers to the precise alignment of printed images from one edge of the substrate to the other, leaving no margins or white spaces. It is important because it ensures a professional appearance, reduces waste, and enhances versatility in printing materials.

How do Visual UV printers achieve accurate registration?

Visual UV printers achieve accurate registration through advanced optical sensors, real-time adjustments, and precision print heads that work together to ensure alignment during the printing process.

What are the benefits of using UV ink in printing?

UV inks cure instantly using ultraviolet light, which allows for faster turnaround times, enhances durability by making prints resistant to scratches and fading, and enables vibrant colors that stand out.

Can Visual UV printers produce prints on various materials?

Yes, Visual UV printers are versatile and can print on a wide range of substrates, including plastics, metals, glass, and wood, making them suitable for various applications.

```