Revolutionizing Branding: UV Printing on Bottles and Tubes with Visual Positioning

Introduction

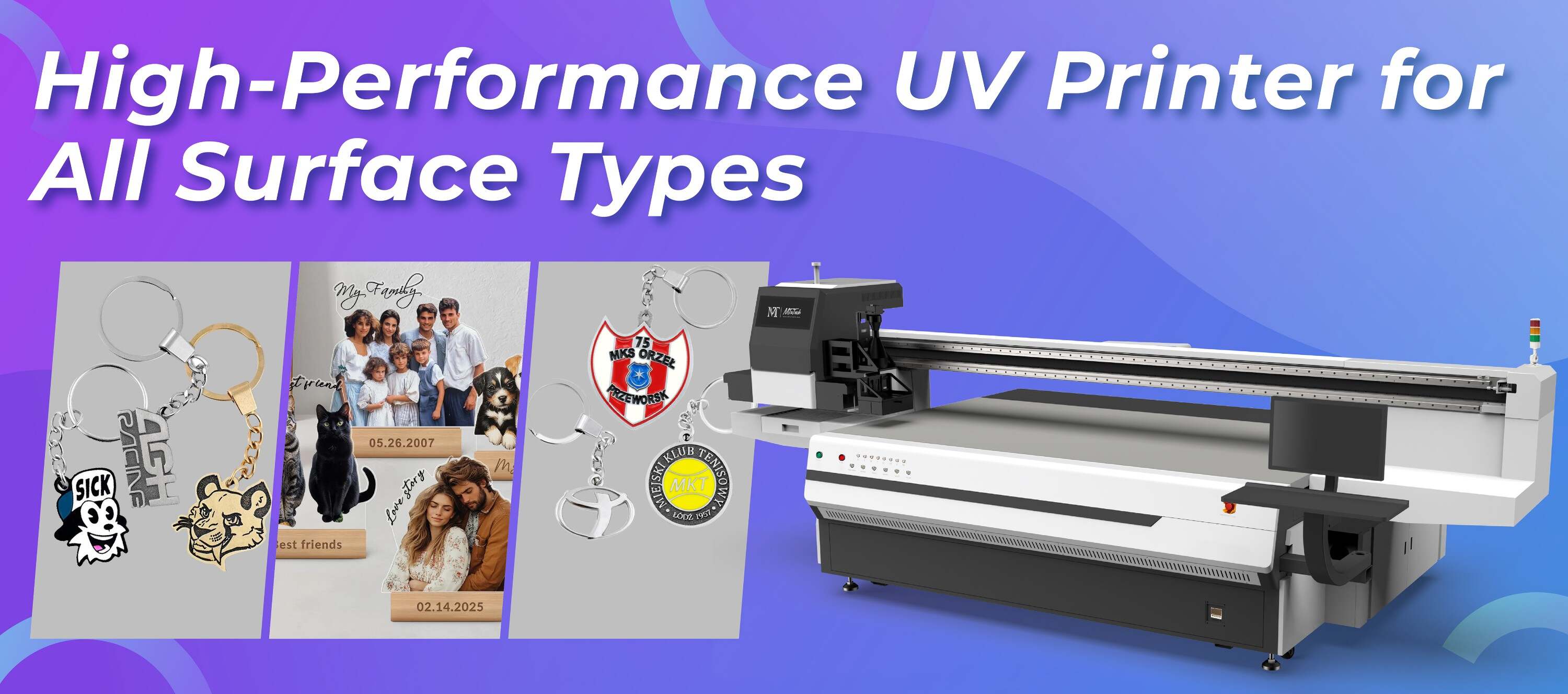

In today's competitive market, branding is more crucial than ever. One of the most effective ways to stand out is through unique and vibrant packaging solutions. UV printing, particularly on bottles and tubes, has emerged as a game changer in the realm of product branding and customization. This advanced printing technology not only enhances visual appeal but also offers unparalleled precision and quality. Coupled with visual positioning technology, UV printing can further elevate the branding experience. In this blog post, we will delve into the intricacies of UV printing on bottles and tubes using visual positioning, exploring its benefits, features, and applications.

What is UV Printing?

UV Printing, or Ultraviolet Printing, is a modern printing technique that utilizes ultraviolet light to dry or cure ink as it is printed. Unlike traditional printing, where ink is absorbed into the substrate, UV printing allows the ink to sit on top of the material, creating a vibrant and durable finish. This technology is particularly suited for diverse materials, including glass, plastic, metal, and more, making it ideal for bottles and tubes.

Benefits of UV Printing on Bottles and Tubes

When it comes to branding and packaging, the benefits of UV printing are plentiful. Here are some of the most significant advantages:

·

Vibrant Colors: UV printing allows for a wide color spectrum, enabling brands to showcase their logos and designs vibrant, eye-catching colors.

·

·

Durability: The cured ink is resistant to scratches, fading, and chemicals, ensuring that the branding remains intact throughout the product's lifecycle.

·

·

Fast Production Time: The curing process is immediate, which translates to faster production times and quicker turnaround for clients.

·

·

Eco-Friendly: UV printing uses less energy and generates fewer volatile organic compounds (VOCs), making it a more environmentally friendly choice compared to traditional printing methods.

·

·

Customization: Brands can easily customize their packaging to suit specific marketing campaigns or seasonal promotions.

·

Visual Positioning Technology Explained

Visual positioning is an innovative technology that enhances the accuracy of UV printing. By utilizing camera systems and software algorithms, visual positioning technology accurately identifies the exact location on the bottle or tube for printing, ensuring that designs align perfectly every time. This technology is essential for:

·

Ensuring precision in placement, especially on curved surfaces.

·

·

Reducing the chances of misprints and wasted materials.

·

·

Allowing for multi-sided printing without manual adjustments.

·

Features of UV Printing with Visual Positioning

1. Precision Calibration

With visual positioning, calibration is streamlined. The system identifies the contours and features of the bottle or tube, allowing for precise placement of designs without manual input.

2. Multi-Surface Capability

This technology is not limited to flat surfaces. Visual positioning enables print on complex geometries, making it ideal for a variety of bottle and tube shapes, from standard to uniquely shaped designs.

3. Speed and Efficiency

This printing technology significantly reduces production times. The automatic alignment ensures a seamless process, allowing businesses to meet tight deadlines without compromising quality.

4. Consistency

One of the standout features of visual positioning is its ability to provide consistent results across multiple runs. Brands can rely on uniformity in branding elements, enhancing brand recognition.

5. Enhanced Creativity

The technology allows for greater creativity in packaging design. Brands can experiment with colors, textures, and finishes without the fear of misalignment or inconsistencies.

Applications of UV Printing on Bottles and Tubes

The versatility of UV printing means it can be applied across various industries. Here are some key applications:

·

Cosmetics and Personal Care: High-quality prints on bottles for lotions, shampoos, and perfumes capture consumers' attention and enhance the aesthetic appeal.

·

·

Food and Beverage: UV printing can be used for packaging bottles for sauces, juices, and other liquids, providing eye-catching designs while adhering to safety regulations.

·

·

Pharmaceuticals: Clear and precise labeling is essential in this industry. UV printing ensures that information is legible and prominent on medication containers.

·

·

Household Products: From cleaning supplies to home fragrances, UV printing helps brands stand out on store shelves with unique packaging designs.

·

Why Choose UV Printing with Visual Positioning?

Brands looking to make a lasting impression on consumers should consider the integration of UV printing with visual positioning technology. This combination offers a powerful solution for unique branding that resonates with customers. With the capability to produce high-quality, customizable designs that are durable and eye-catching, businesses can significantly enhance their marketing efforts.

Moreover, having a reliable printing partner equipped with the latest technology ensures that brands can achieve their packaging goals without hassle. For those interested in this advanced printing solution, explore our high-quality Visual Positioning UV printers here.

Conclusion

UV printing on bottles and tubes, when combined with visual positioning technology, represents a significant advancement in the field of packaging and branding. The benefits of durability, vibrant colors, and customization opportunities create a competitive edge for brands aiming to capture market share. By embracing these technologies, businesses can set themselves apart, enhance customer engagement, and ultimately drive sales. The future of packaging is bright, and UV printing is at the forefront of that evolution.

FAQ

What materials can be used for UV printing?

UV printing can be applied to a wide variety of materials, including glass, plastic, metal, wood, and paper. This versatility makes it suitable for a range of products, from bottles and tubes to promotional items.

Is UV printing environmentally friendly?

Yes, UV printing is considered more environmentally friendly compared to traditional printing methods. It uses less energy and produces fewer volatile organic compounds (VOCs), contributing to a reduced environmental impact.

How long does UV printing last?

UV printing produces durable prints that are resistant to scratches, fading, and chemicals. With proper care, UV prints can last for many years, even under challenging conditions.

What is visual positioning in UV printing?

Visual positioning is a technology that enhances the accuracy of UV printing by using camera systems to identify the exact placement for printing on various surfaces, ensuring precision and uniformity.

Can UV printing be used for complex bottle shapes?

Yes, UV printing with visual positioning technology excels with complex bottle shapes. The technology ensures precise alignment and placement, allowing for creative designs on any surface.