Understanding Visual Positioning UV Printer Image Stitching for Large Beds

Introduction

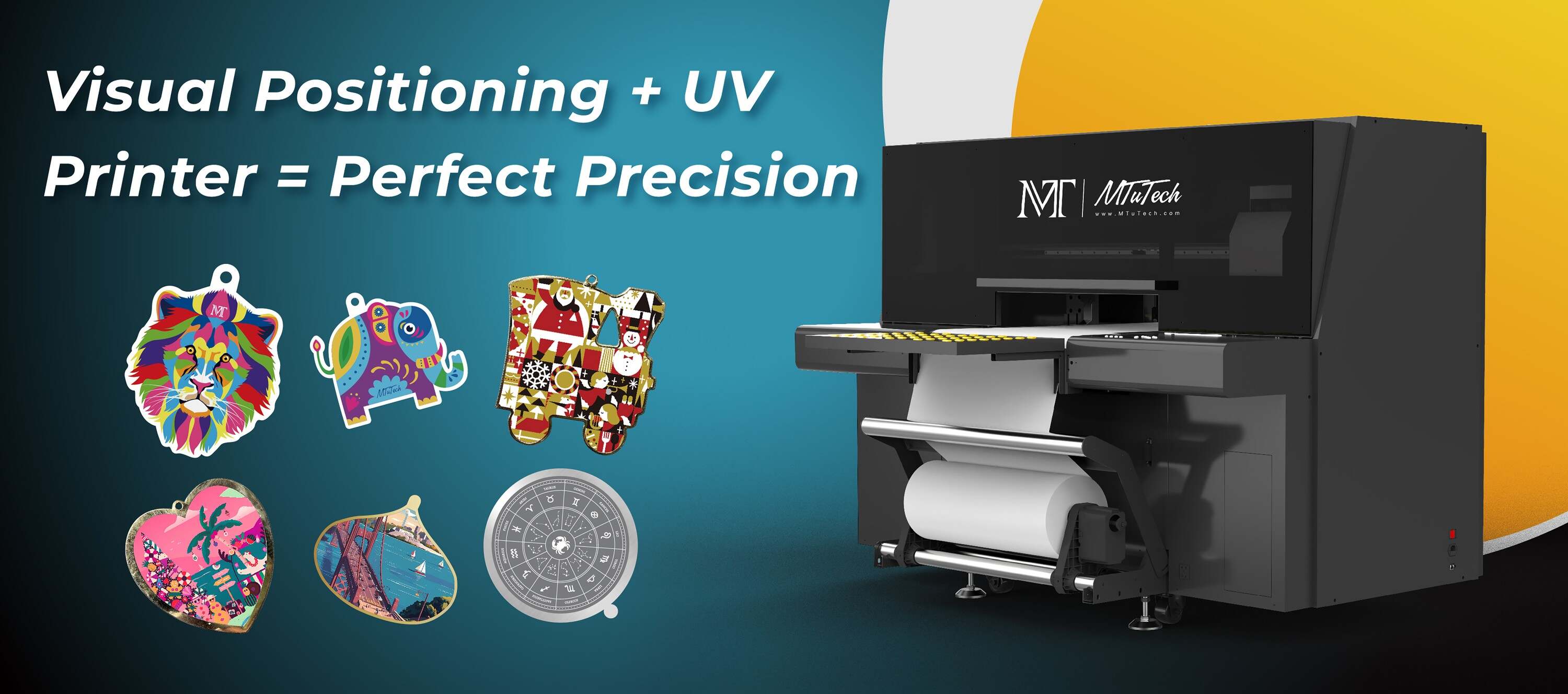

In the world of modern printing technology, the capability to create large-format prints is vital for businesses across various industries. One of the most innovative solutions for this challenge is the Visual Positioning UV Printer. This advanced technology has streamlined the process of image stitching for large beds, enabling users to achieve seamless, high-quality prints. In this comprehensive guide, we will explore the fundamentals of visual positioning, the intricacies of image stitching, and how these features can significantly enhance your printing operations.

What is Visual Positioning UV Printing?

Visual Positioning UV Printing is a cutting-edge technology that employs advanced imaging techniques to precisely align and print large images on expansive surfaces. Unlike traditional printing methods that may struggle with alignment and continuity, visual positioning leverages real-time feedback and intelligent software algorithms to ensure that every part of the image fits perfectly, even when using oversized printers.

Key Components of Visual Positioning

The technology consists of several crucial components:

·

Sensors: These are used to detect the exact position of the printer head relative to the substrate, allowing for precise adjustments to be made in real-time.

·

·

Software Algorithms: Advanced algorithms process the data from the sensors to ensure that images are consistently aligned, leading to a seamless print.

·

·

UV Curing Technology: UV printers utilize ultraviolet light to cure (dry) the ink almost instantaneously, which minimizes smudging and enhances print durability.

·

The Importance of Image Stitching in Large Bed Printers

Image stitching is a critical feature when dealing with large bed printers. It refers to the process of combining multiple images into a single cohesive print. This is particularly essential for large projects where a single image exceeds the dimensions of the printer's bed. Without effective stitching techniques, the final product may appear disjointed or inconsistent.

How Image Stitching Works

The process involves the following steps:

·

Initial Setup: The image to be printed is divided into sections based on the printer’s print area.

·

·

Alignment: Using visual positioning technology, the printer head aligns with the beginning of the print section.

·

·

Printing: The printer then prints each section; sensors monitor the printhead’s position, ensuring accuracy.

·

·

Curing: Once printed, the UV light cures the ink in real-time, ensuring that each section is immediately set before the next one is printed.

·

·

Final Integration: After all sections are printed, they are stitched together digitally, creating the final large-format image with a professional finish.

·

Benefits of Using Visual Positioning UV Printers with Image Stitching

The combination of visual positioning and image stitching brings numerous advantages to businesses that depend on high-quality large-format prints.

1. Enhanced Precision

Visual positioning technology ensures every section is perfectly aligned, significantly reducing the chances of misprints and the need for corrections.

2. Improved Efficiency

Real-time monitoring and adjustments allow printers to produce large images quickly without compromising quality, leading to increased productivity and lower turnaround times.

3. Greater Versatility

These printers can handle a variety of materials, from rigid substrates to flexible vinyl, making them suitable for diverse applications such as signage, banners, and decor.

4. Cost Savings

Minimizing wasted materials and reducing errors leads to significant cost savings for businesses, allowing them to allocate resources more efficiently.

5. High-Quality Outputs

The instant curing process employed by UV printers ensures vibrant colors and sharp images, which are vital for maintaining brand quality and appeal.

Features to Look For in Visual Positioning UV Printers

When considering a Visual Positioning UV Printer, take note of the following essential features:

1. Bed Size

Ensure the printer can accommodate the sizes of the materials you plan to print. Larger beds allow for more significant projects and reduce the need for extensive image stitching.

2. Print Resolution

High print resolution is crucial for quality output. Look for printers capable of delivering fine details, particularly for textiles and graphics.

3. Speed and Throughput

Examine the printer's speed capabilities to ensure it meets your production needs without sacrificing print quality.

4. Material Compatibility

Consider the range of materials that can be used, as versatile printers open up new avenues for creativity and business possibilities.

5. User-Friendly Interface

An intuitive interface can make operating the machine simpler, allowing operators to focus on creativity rather than dealing with complex controls.

Conclusion

Understanding the functionality of Visual Positioning UV Printers and the significance of image stitching for large beds can greatly enhance your printing operations. By leveraging this technology, businesses can achieve superior quality prints while maintaining efficiency and cost-effectiveness. As the demands for large-format printing continue to rise, investing in a reliable and advanced UV printer is vital for staying competitive in the industry.

For those interested in enhancing their printing capabilities, consider exploring our high-quality Visual Positioning UV printers here.

FAQ

What types of materials can be printed using Visual Positioning UV Printers?

Visual Positioning UV Printers can print on a wide range of materials, including plastics, metals, glass, wood, and specially coated materials, making them highly versatile for various applications.

How does image stitching affect print quality?

Effective image stitching is crucial for ensuring that large prints appear seamless and cohesive. Poor stitching can lead to visible seams or misalignment, negatively impacting the overall print quality.

What are the maintenance requirements for UV printers?

Routine maintenance includes cleaning the print heads, updating software, and ensuring that sensors are functioning correctly. Some manufacturers provide specific guidelines to keep your printer in optimal condition.

Can Visual Positioning UV Printers be used for small-format prints?

While they are designed for large-format printing, these printers can also be used for smaller prints. However, users may want to consider whether a smaller format printer would be more efficient for specific small-scale projects.

What is the average lifespan of a Visual Positioning UV Printer?

The lifespan of a UV printer can vary based on usage and maintenance, but many high-quality models are built to last for several years with proper care. Regular maintenance can prolong the printer's life significantly.