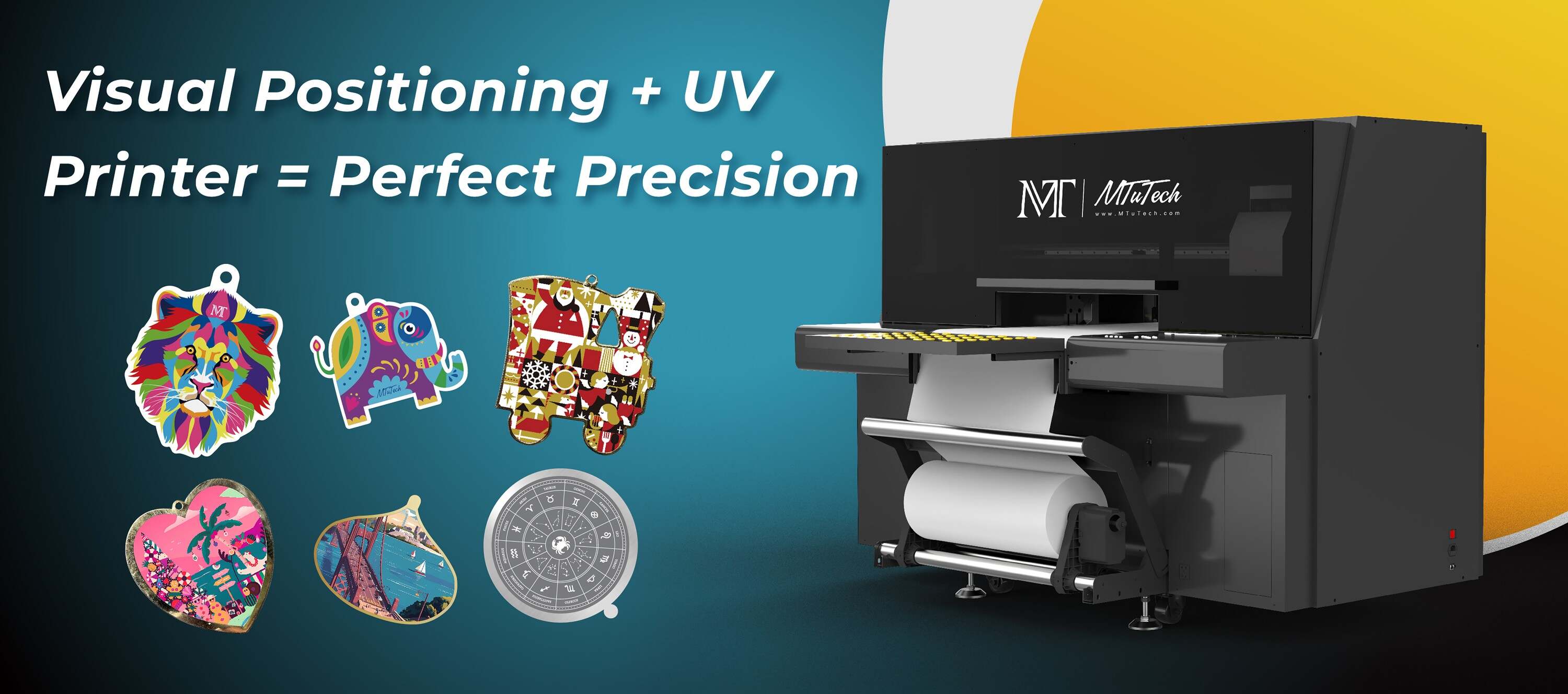

Visual Positioning UV Printing for Cylindrical and Irregular Shapes

Introduction

In the world of printing, the demand for high-quality results on various surfaces has led to innovative technologies and solutions. Among these, Visual Positioning UV (Ultraviolet) printing stands out, especially when it comes to printing on cylindrical and irregular shapes. This technique is rapidly gaining popularity in industries such as packaging, promotional products, and custom merchandise. In this blog post, we will explore the numerous benefits and features of Visual Positioning UV printing and how it can transform your printing capabilities.

What is Visual Positioning UV Printing?

Visual Positioning UV printing is an advanced printing technology that utilizes UV light to cure or dry ink as it is printed onto surfaces. This method allows for precise application of ink on a variety of shapes, including cylindrical and irregular objects, which are traditionally challenging to print on. The visual positioning aspect refers to the ability of the printer to align the print accurately with the design, ensuring consistent quality and detail.

Benefits of Visual Positioning UV Printing

There are several compelling advantages to using Visual Positioning UV printing, particularly when it comes to cylindrical and irregular shapes:

·

High Precision: The advanced alignment features allow for meticulous positioning, which is crucial for complex shapes.

·

·

Versatility: Capable of printing on diverse materials, including plastic, glass, metal, and wood.

·

·

Vibrant Colors: UV inks produce bright, sharp images that are resistant to fading, ensuring long-lasting quality.

·

·

Eco-Friendly: UV printing is more environmentally friendly than traditional printing methods, as it emits fewer volatile organic compounds (VOCs).

·

·

Instant Drying: The UV curing process allows for immediate handling of printed products, speeding up production times.

·

Applications of Visual Positioning UV Printing

This advanced printing technology is widely used across various industries and applications, making it a versatile option for businesses looking to enhance their product offerings. Here are some key applications:

1. Promotional Products

From custom mugs to unique souvenirs, Visual Positioning UV printing enables businesses to create visually appealing promotional items that effectively convey their brand message.

2. Packaging Solutions

With the capability to produce high-quality prints on irregular packaging shapes, this technology enhances product branding and shelf appeal.

3. Decorative Items

Artists and designers can utilize this technique to create unique pieces of art on a variety of substrates, ensuring that every detail is captured beautifully.

4. Industrial Applications

Used for marking and coding on cylindrical products such as bottles or tubes, Visual Positioning UV printing enhances traceability and compliance in manufacturing.

Features of Visual Positioning UV Printing

Understanding the features of Visual Positioning UV printing can help businesses make informed decisions about their printing solutions:

·

Advanced Imaging Technology: This feature allows for high-resolution prints, ensuring fine details are maintained, even on intricate designs.

·

·

Automated Registration: Automatic alignment of the printing head to the object surface minimizes human error.

·

·

Variable Size Compatibility: The ability to handle various object sizes and shapes without compromising quality.

·

·

Multiple Ink Options: Available in various finishes, including matte and gloss, providing flexibility in design choices.

·

·

User-Friendly Interface: Most modern printers come equipped with intuitive software that simplifies the design and printing process.

·

Challenges Overcome by Visual Positioning UV Printing

While traditional printing methods have served industries well for many years, they often come with limitations when it comes to irregular or cylindrical shapes. Visual Positioning UV printing addresses several of these challenges:

1. Shape Limitations

Conventional printing methods often struggle with the contours of cylindrical or irregular objects. Visual Positioning technology allows printers to adapt and print seamlessly on these surfaces.

2. Ink Adhesion Issues

Some surfaces have difficulty retaining ink, leading to fading or chipping. UV inks cure instantly when exposed to UV light, ensuring strong adhesion and durability.

3. Time-Consuming Setup

Traditional setups can be time-consuming, especially when changing designs or shapes. Visual Positioning UV printers streamline this process, allowing for quick job changes and reduced downtime.

Conclusion

Visual Positioning UV printing represents a significant advancement in the printing industry, particularly for businesses needing to print on cylindrical and irregular shapes. With its exceptional precision, vibrant colors, and versatility across various applications, it's no wonder that this technology is becoming a preferred choice for companies aiming to enhance their product offerings. If you are looking to elevate your printing capabilities and meet the demands of your customers, explore our high-quality Visual Positioning UV printers here.

FAQ

What types of materials can be printed using Visual Positioning UV printing?

Visual Positioning UV printing can be performed on a wide range of materials, including plastic, glass, metal, wood, ceramics, and more. The versatility of this method makes it suitable for numerous applications across various industries.

How does the UV curing process work?

The UV curing process involves exposing the applied UV ink to UV light, which triggers a chemical reaction that causes the ink to harden almost instantly. This allows for quicker production times and enhances the durability of the printed design.

Is Visual Positioning UV printing environmentally friendly?

Yes, Visual Positioning UV printing is generally considered more environmentally friendly compared to traditional printing methods. UV inks emit fewer volatile organic compounds (VOCs) during the printing process, which helps reduce the overall environmental impact.

Can Visual Positioning UV printers handle large batches?

Yes, many Visual Positioning UV printers are designed to handle large production runs efficiently, making them suitable for both small and large batch printing.

What industries benefit from Visual Positioning UV printing?

Multiple industries benefit from Visual Positioning UV printing, including packaging, promotional products, textiles, industrial applications, and decorative arts, among others. The technology's adaptability allows it to meet diverse needs effectively.