Introduction

In the world of printing, innovation is key to creating high-quality and varied outputs. Among the latest advancements is the UV Direct to Film (UV DTF) printing technology, which allows for exceptional versatility in printing on different materials. This blog post will guide you through what UV DTF printing is, its benefits, features, and a detailed step-by-step process on how to achieve stunning results.

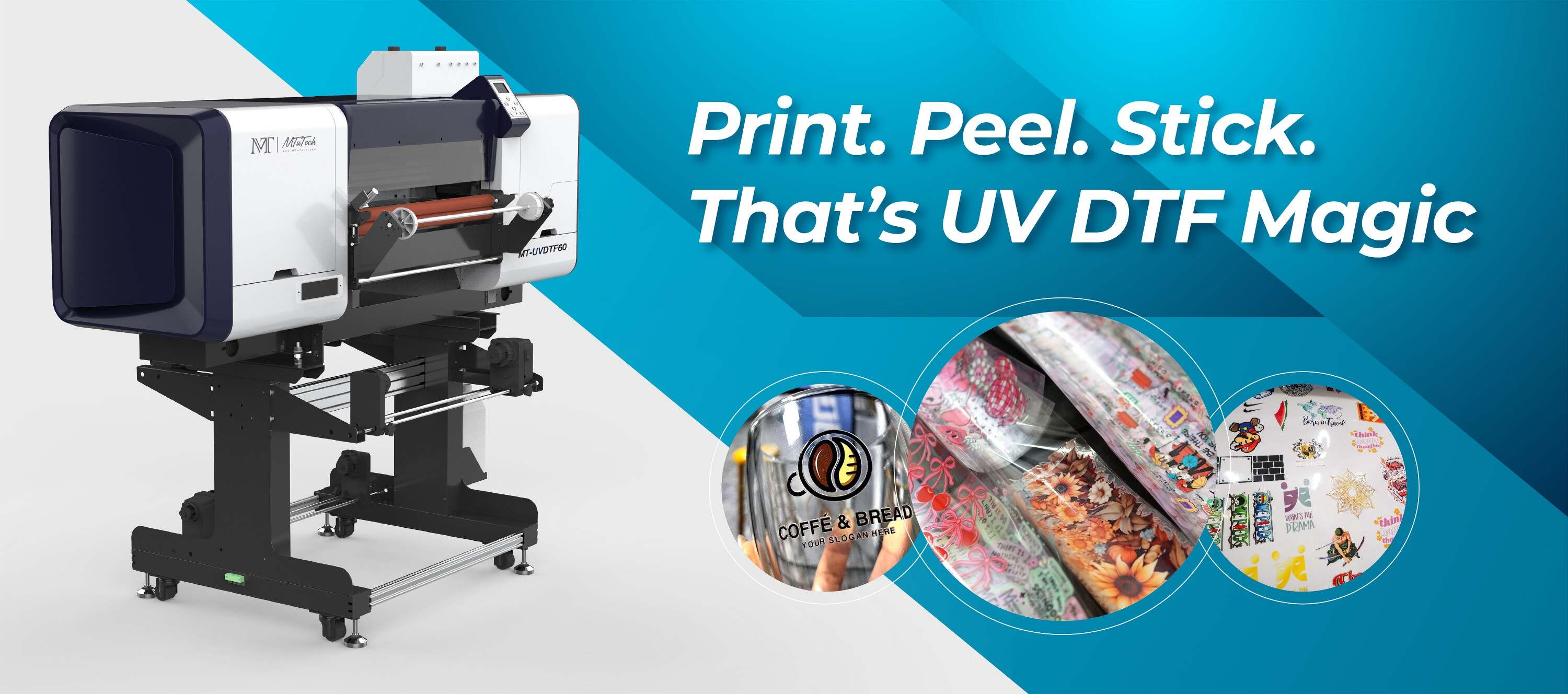

What is UV DTF Printing?

UV DTF printing is a modern method that combines the benefits of UV printing with the Direct to Film technique. This process involves printing images directly onto a film substrate using UV-curable inks. These inks are cured instantly by ultraviolet light, ensuring vibrant colors and durability. The end result is a high-quality print that can adhere to various surfaces, making it ideal for promotional items, apparel, and much more.

Benefits of UV DTF Printing

The advantages of UV DTF printing make it a popular choice among businesses and artists alike. Here are some key benefits:

Versatility: UV DTF printing can be applied to a wide range of materials, including plastics, fabrics, glass, and metal.

Durability: The UV-cured inks are highly resistant to scratching, fading, and water, ensuring that your prints last longer.

Vibrant Colors: The printing process allows for the reproduction of vivid colors and fine details, enhancing the overall quality of the final product.

Eco-Friendly Options: Many UV inks are designed to be environmentally friendly, producing fewer volatile organic compounds (VOCs) during the printing process.

Cost-Effective: With minimal setup requirements and efficient printing capabilities, UV DTF printing can reduce production costs.

Key Features of UV DTF Printers

Understanding the features of a UV DTF printer is crucial for choosing the right one for your needs. Here are some essential features to consider:

Print Size: Assess the maximum print size to ensure it meets your project requirements.

Ink Types: Different printers may use various types of UV inks; look for those that offer a wide color gamut.

Printing Speed: Depending on your production demands, consider the printing speed of the machine.

Resolution: Higher resolution printers will produce finer details and better quality prints.

Easy Maintenance: Look for printers that are easy to clean and maintain to reduce downtime.

Step-by-Step Guide to UV DTF Printing

Now, let’s dive into the process of UV DTF printing. Follow these steps to achieve successful results:

Step 1: Prepare Your Design

Before printing, you need to prepare your digital design. Make sure to use a high-resolution file (at least 300 DPI) for the best results. Popular design software includes Adobe Illustrator and CorelDRAW. Save your final design in a format compatible with your printer, such as TIFF or PNG.

Step 2: Choose the Right Film

Select the appropriate DTF film, which is available in various types based on the intended material. Ensure that the film can withstand UV exposure and has the required coating for effective ink adhesion.

Step 3: Set Up Your Printer

Follow your UV DTF printer's instructions to set it up properly. This includes loading ink, installing the print head, and configuring settings such as resolution, speed, and the type of film being used. Remember to check for software updates that could enhance functionality.

Step 4: Print the Image

Load the DTF film into the printer, ensuring it is aligned correctly. Use the printer’s software to send your design to the printer. Monitor the print process to ensure that the colors are coming out as expected and that there are no technical issues. Once printed, let the ink cure under the UV light installed on the printer.

Step 5: Finishing Touches

After the printing and curing process, carefully remove the film. If necessary, trim any excess film around the design. This is the stage where you can also apply additional coatings if required to enhance durability.

Step 6: Applying the Print

The final step is to transfer the print to your desired substrate. Depending on what you are working with, ensure that the surface is clean and free of dust. Use heat transfer techniques or adhesive methods to apply the print onto the object.

Best Practices for UV DTF Printing

To get the most out of your UV DTF printing experience, consider the following best practices:

Regular Maintenance: Ensure your printer is regularly cleaned and serviced to maintain optimal performance.

Test Prints: Always conduct test prints before starting on larger projects to avoid unnecessary waste.

Use Quality Materials: Invest in high-quality inks and films to get the best results.

Stay Updated: Keep abreast of the latest trends and technologies in printing to improve efficiency and quality.

Conclusion

UV DTF printing offers a revolutionary approach to creating high-quality prints across various materials. By following the steps outlined in this guide, you'll be well on your way to producing vibrant, durable prints that can elevate your product offerings. For high-quality UV-DTF printers that suit your needs, explore our high-quality UV-DTF printers here and take your printing capabilities to the next level.

FAQ

What materials can be printed using UV DTF printing?

UV DTF printing can be used on a variety of materials, including plastics, textiles, glass, metal, and even wood. Its versatility makes it suitable for a wide range of products.

How long do UV DTF prints last?

When properly cured and maintained, UV DTF prints are highly durable and can last for many years, resisting fading, scratching, and damage from water.

Is UV DTF printing eco-friendly?

Many UV inks are formulated to be low in volatile organic compounds (VOCs), making UV DTF printing a more eco-friendly option compared to traditional solvent inks.

Can I print on dark materials with UV DTF?

Yes! One of the advantages of UV DTF printing is its ability to print on dark materials. The opaque ink can provide vibrant colors and intricate designs on darker substrates.

What is the difference between UV printing and UV DTF printing?

UV printing typically involves printing directly onto a surface, whereas UV DTF printing involves first printing on a film and then transferring that print to the final substrate. This flexibility allows for more intricate designs and applications.