Printing on Textured Surfaces Using Visual Positioning Adjustments

Printing on Textured Surfaces Using Visual Positioning Adjustments

Introduction

In today's dynamic printing landscape, the ability to print on textured surfaces presents exciting opportunities for creativity and innovation. Traditional methods can struggle with uneven surfaces, resulting in misaligned prints and unsatisfactory results. Fortunately, advancements in printing technology, particularly visual positioning adjustments, have revolutionized how we approach this challenge. This blog explores the benefits, features, and techniques involved in utilizing visual positioning adjustments for printing on textured surfaces.

The Importance of Visual Positioning Adjustments

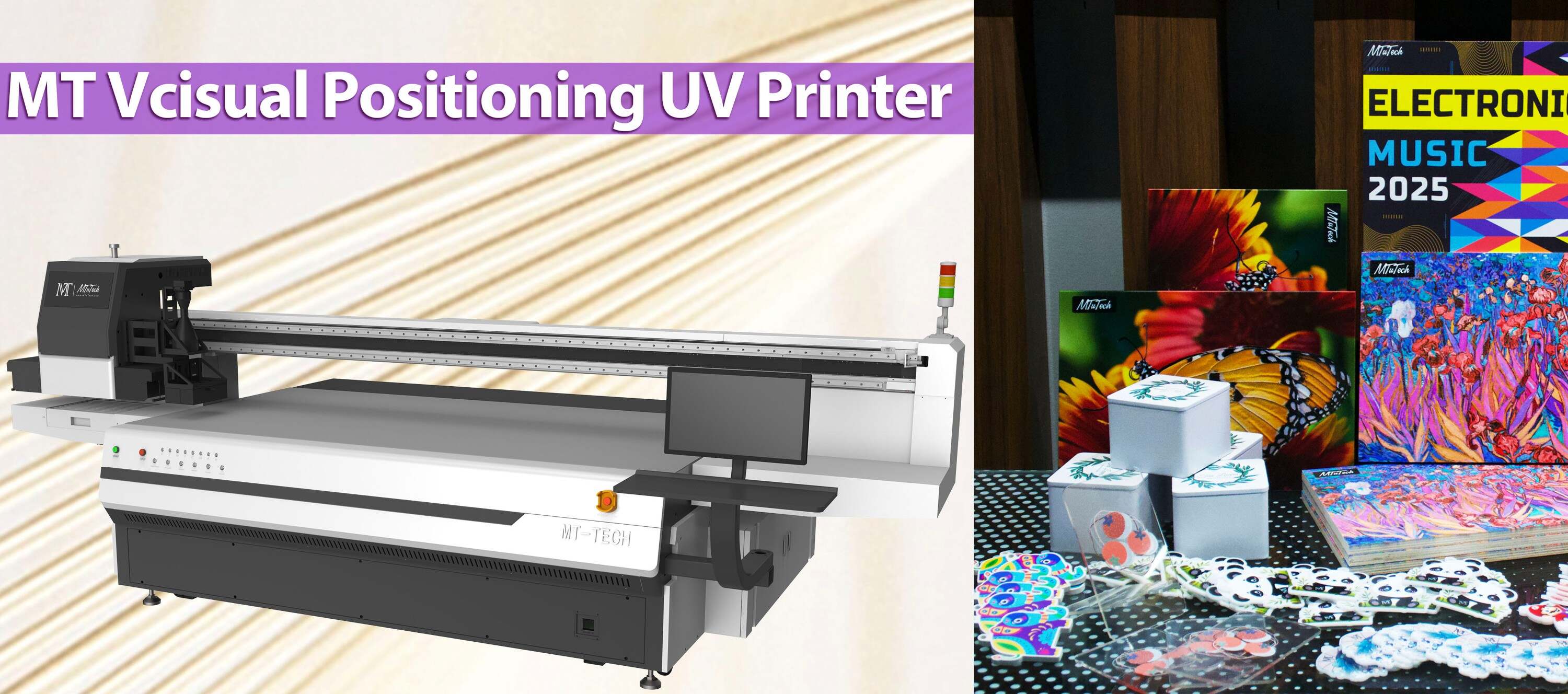

Visual positioning adjustments, particularly in the context of UV printers, allow for precise placement of images and designs on irregular surfaces. This technology employs advanced sensors and software to detect surface contours, ensuring that the printed media aligns perfectly with the substrate, regardless of its texture or shape. As a result, businesses can create unique products that stand out in a competitive market.

Benefits of Printing on Textured Surfaces

Enhanced Aesthetics

Printing on textured surfaces can add depth and interest to a design. The interplay of lighting and shadow created by the texture can enhance the visual appeal, making the final product more engaging.

Unique Product offerings

Businesses looking to set themselves apart can leverage textured surfaces to create one-of-a-kind products. This can apply to packaging, promotional items, or custom decor, allowing brands to emphasize their identity through innovative design.

Durability and Longevity

Textured surfaces can enhance print durability. The unique characteristics of these surfaces often offer better adhesion, reducing the risk of fading or wear over time, which is essential for products that need to withstand time and usage.

Features of UV Printers with Visual Positioning Adjustments

Modern UV printers equipped with visual positioning adjustments offer a range of features that enhance their usability and efficiency when printing on textured surfaces. Let’s delve into some key features:

·

Automatic Surface Recognition: UV printers can automatically detect the surface texture and adjust the printing parameters accordingly to ensure optimal adhesion and alignment.

·

·

Height Mapping Technology: This feature measures surface variations and ensures that print heads adjust their height in real-time, preventing print defects caused by uneven surfaces.

·

·

Intelligent Ink Management: Advanced systems manage ink flow to accommodate surface conditions, ensuring consistent ink coverage and quality on textured materials.

·

·

Color Calibration: Automated color calibration adjusts to the surface’s characteristics, allowing for precise color reproduction even on complex textures.

·

Techniques for Successful Printing on Textured Surfaces

Surface Preparation

Before starting the printing process, it's critical to prepare the surface. Ensure that it's clean, free of dust, oil, or any debris that might hinder adhesion. Surface preparation can significantly impact the print quality and durability, especially on textured surfaces.

Adjusting Printer Settings

Each textured surface may require different printer settings. It's essential to adjust parameters such as height, speed, and ink flow. Experimenting with these settings will lead to the best results.

Testing Sample Prints

Always run a test print on a similar textured surface before launching into full production. This allows for the assessment of quality, colors, and alignment, providing a chance to make necessary adjustments without wasting materials.

Common Applications for Textured Surface Printing

Printing on textured surfaces is utilized across various industries, showcasing its versatility:

·

Packaging: Unique packaging with textured finishes can differentiate products on shelves, capturing consumers' attention immediately.

·

·

Promotional Materials: Brochures, business cards, and other marketing materials can be printed on textured papers, leaving a memorable impression.

·

·

Interior Design: Wall art, signs, and decorations with printed textures add character and individuality to spaces.

·

Challenges Faced in Textured Surface Printing

While the potential is significant, printing on textured surfaces comes with its own set of challenges:

·

Inconsistent Quality: Variations in texture can lead to inconsistent prints. Careful adjustments and testing are required to achieve uniform results.

·

·

Increased Production Time: The process might take longer due to the need for meticulous preparation and settings adjustments, affecting productivity.

·

·

Higher Costs: Advanced printers and materials may require greater investment, which could impact overall production budgets.

·

Conclusion

Printing on textured surfaces using visual positioning adjustments opens up a world of possibilities for businesses looking to innovate and stand out. From enhancing aesthetics to creating unique products, the benefits of this technology are numerous. By understanding the features of modern UV printers and employing effective techniques, organizations can successfully address the challenges posed by textured surfaces, ultimately leading to higher customer satisfaction and market differentiation. For those interested in incorporating this cutting-edge technology into their operations, explore our high-quality Visual Positioning UV printers here and take the first step towards transforming your printing capabilities.

FAQ

What types of textured surfaces can I print on?

You can print on a wide range of textured surfaces, including wood, fabric, metals, plastics, and specially textured papers. Each surface may require different settings and preparations for the best results.

How does visual positioning adjustment improve printing accuracy?

Visual positioning adjustments enhance printing accuracy by utilizing sensors to detect surface contours and automatically adjust the print head height and ink application. This ensures that images are precisely aligned with the surface, accounting for any irregularities.

Are there specific maintenance requirements for UV printers used on textured surfaces?

Yes, UV printers require regular maintenance, such as cleaning the print heads, ensuring proper ink flow, and calibration. Special attention should be given to the printer's settings to adapt to the various textures frequently used.

Can I use the same printer for both smooth and textured surfaces?

Yes, modern UV printers designed with visual positioning adjustments can handle both smooth and textured surfaces. However, you will need to adjust the printer settings based on the surface characteristics to achieve optimal results.