-

Company Advantage

We promoted the technical innovation in the digital inkjet printing facilities production.

The MT Industry has been keeping developing! -

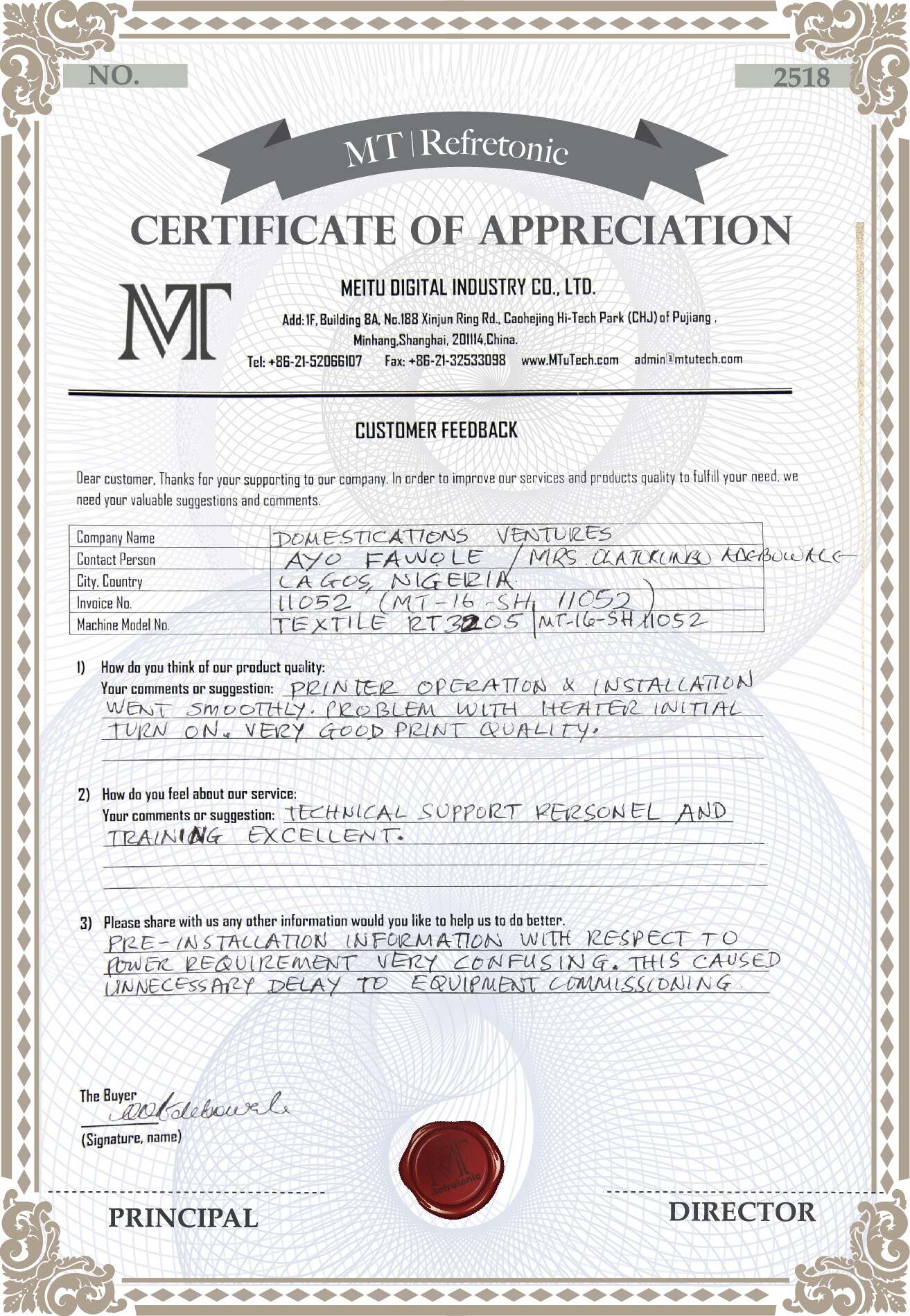

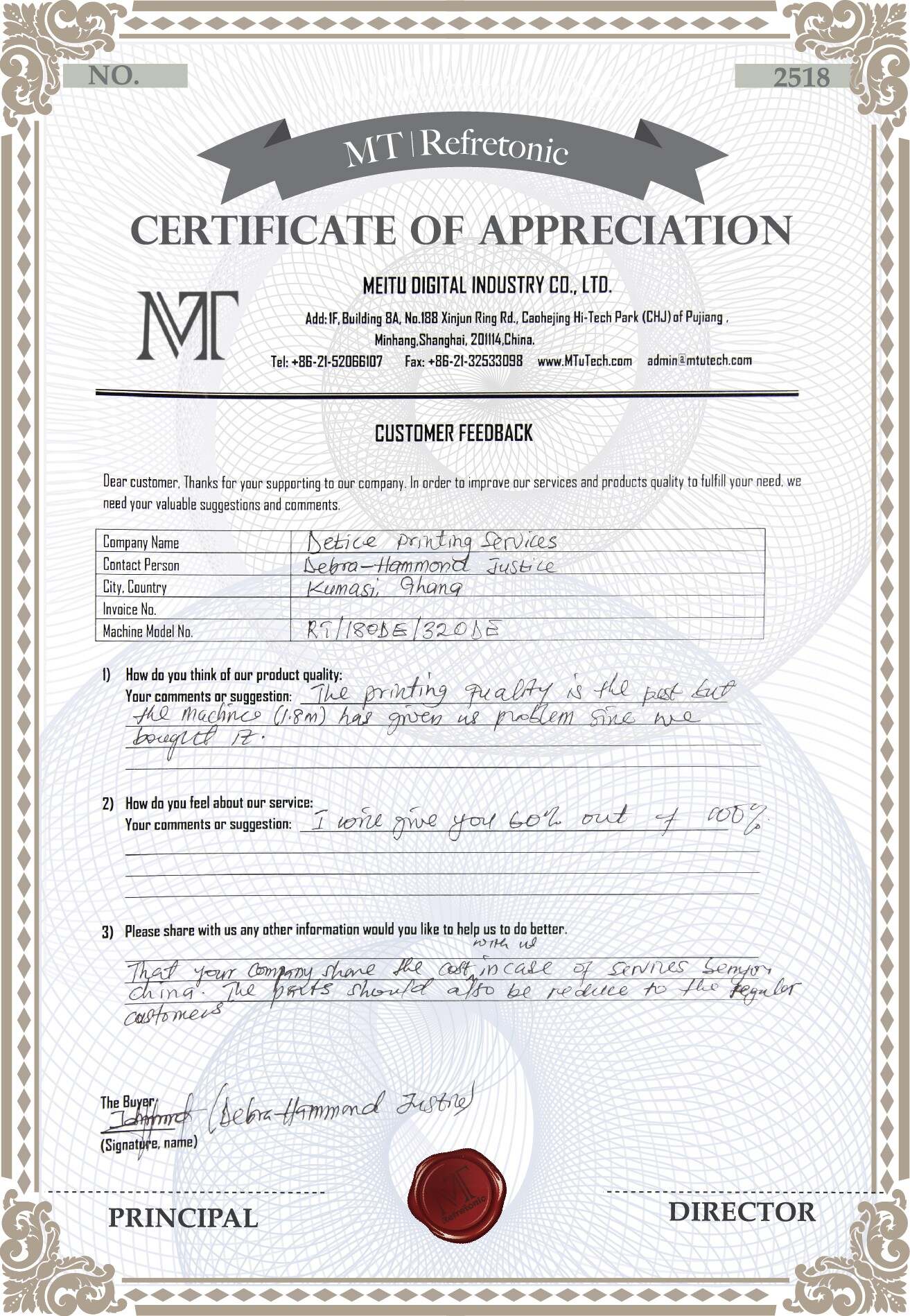

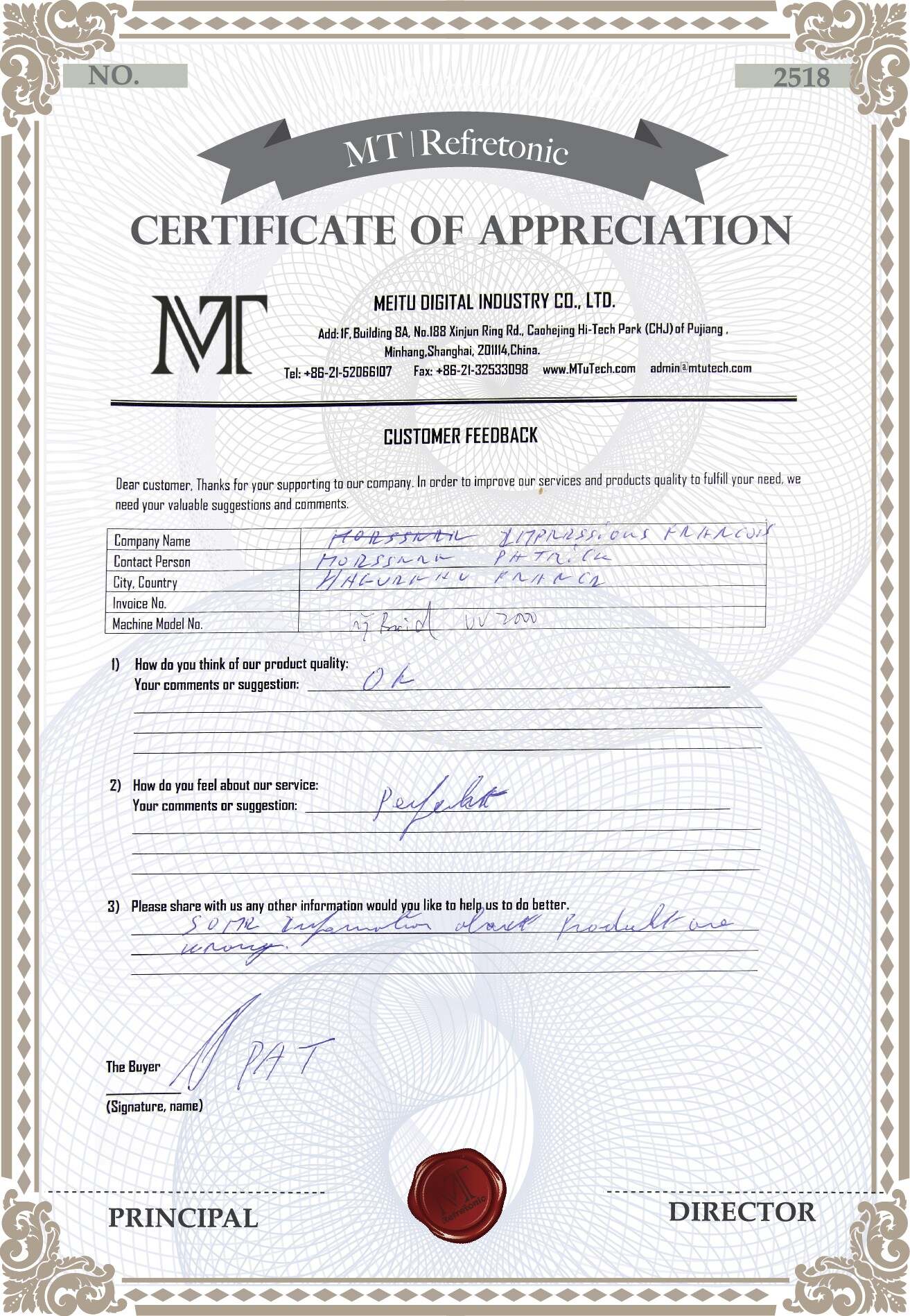

Customer Service

Please contact us if you have any doubt, problem or trouble regarding to our products. Just click “LIVE CHAT”!

-

Guarantee Policy

We provide with 1 year warranty, but gain PERMANENT GUARANTEE with continuous ink order!

-

Payment Terms

We are committed to providing the most convenience payment term; the Client can choose T/T, L/C, PayPal and West union!

-

Packing Standard

The most environmentally friendly and strong packaging, the clients no need worry in the delivery process!

-

Transportation & Delivery

We provide the most convenient, safe, fast Transport after we get the purchase order, even provide home delivery!

Description

MT Sublimation Printer includes one brand new printer and one sublimation heater with fume extractor, directly print to the sublimation textile with sublimation ink, and then through sublimation system to appear and fix the color, after this process printed pictures become very bright. No need any sublimation paper more! The printed textile can work inside and out side, and suitable to wash, no fading for the pictures. It can reduce normal sublimation process, save costs and time, give more efficiency! Our Sublimation system available a few size, It can based customer request to produce different size as you want.

Feature

·Far Infrared Blackbody Tube Radiation Electro thermal Heating

·Intelligent PID Temperature Control

·Digital Tension Control

·Feeding and Taking up Are synchronous

·Vacuum Fan Delivery Is Controllable

·Quick Tail Gas Treatment

·Convenient to Maintain

·Easy to Set up and Operate

·Easy to load the media in and out oven during your machine working

·Easy to open the caver to clean inside of oven

·Special clutch to control the feeding up system working or stop , it’s easy for you loading the roll materials.

·Easy to change the active carbon from the filter

·Adopting the most advanced thermal energy technology low power consumption, saves electricity and conserve energy costs

·High Productivity

Advantage

Exhaust with out any smell, good environment need.

Normal temperture for exhaust, no dangerouse for hot air out.

High Efficiency cold system to make sure the exhaust temperture less then 25 Degree.

Drawer-type device in a timely manner to facilitate the replacement of activated carbon to ensure that the emission of harmful gases.

Application

To Produce Flags, Color Banner, Textile printing etc...

IT IS SIMPLE AND LEAVE OUT HEAT TRANSFER PROCESS ONE PERSON CAN OPERATES WITH HIGH EFFICENCY AND SHORT TIME

LOW COST AND NO NEED OF ANY KIND TRANSFER PAPER, LINER BEAKING THE HIGHEST COSTS PERFORMANCE

Product Specification

| Mode Type | Oven/Heater |

|---|---|

| Power | 6.5KW |

| Working Width | 3200MM |

| Blackbody Tube Working Model | Far Infrared |

| Heat Tuble Dimension | 3520MM |

| Working Temperture | 30 to 400 ℃ |

| Media Max thickness | 13mm |

| Working Voltage Take Up working Method Take Up media diameter(roll to roll) | 380~400 V 50HZ Roll to Roll. 300mm |

| Machine package Dimension | 4250×1100×1300mm |

| Weight | 500Kg |

| Certification | CE Certificated |

| Package | High intensity standard carton package Non Fumigation |

| Available Printer | Mimaki, Roland , Mutoh and any Piazo Printer |

| Mode Type | Fume Extractor |

|---|---|

| Power | 360W |

| Working Voltage | 220~240V 50HZ |

| Package Size | 620X565X1100mm |

| Weight | 60 Kg |

| Input Air temperature | >200 ℃ |

| Out put Air temperature | <25 ℃ |

| Filter Medium | Active Carbon |

| Certification | CE Certificated |