Introduction

Introduction

UV DTF printing relies on more than just beautiful artwork — it’s backed by chemistry and light. At the heart of this process is UV curing: a fast, clean, and efficient method of turning liquid ink into a solid, durable print. In this article, we break down the science behind UV ink curing and how it affects your final DTF output.

What is UV Ink Curing?

- UV curing is a photochemical process where ultraviolet light instantly hardens specially formulated inks

- Instead of evaporating like solvent inks, UV inks polymerize — meaning they chemically transform into a solid film

How UV Curing Works in DTF Printing

- Ink is applied onto the A film through nozzles

- UV LED lamps (attached to the printhead or carriage) emit UV light

- Photoinitiators in the ink absorb the light and trigger polymerization

- Cured ink is instantly dry, allowing for immediate lamination and transfer

Benefits of UV Ink Curing

- Instant Drying: Increases print speed and reduces smudging

- Strong Adhesion: Cured ink forms a bond that’s resistant to scratching and water

- Vibrant Color: UV inks remain on the surface, making colors more opaque and vivid

- No VOC Emissions: Environmentally friendly compared to solvent inks

Factors That Affect Curing Efficiency

- Lamp Power & Distance: Closer, stronger light cures faster and more evenly

- Ink Thickness: Heavier ink loads may need multiple passes

- Ambient Temperature: Cold rooms can slow chemical reactions

- Film Quality: Lower-grade A film may not absorb or reflect UV light correctly

How to Test for Proper Curing

- Lightly scratch the print — if ink flakes off, it's undercured

- Use a UV dot test card to measure exposure

- Run small prints and inspect edges for tackiness

Conclusion

Understanding UV curing helps you make smarter printing decisions, from choosing inks and films to adjusting printer settings. The result? Cleaner, stronger, and longer-lasting prints that make your UV DTF products stand out.

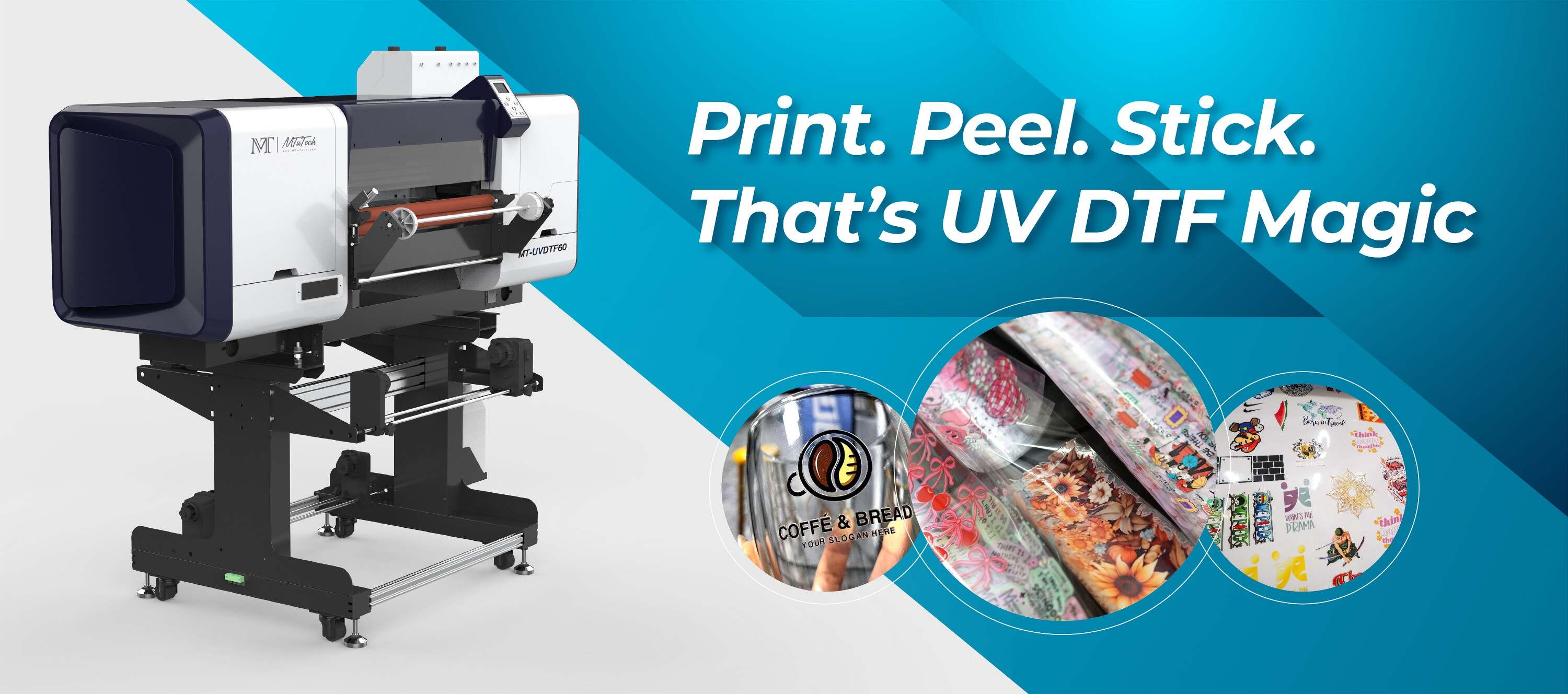

Powered by precision curing, our next-gen UV DTF printer ensures clean, durable prints with perfect polymerization.