Introduction

When it comes to printing designs on various materials, businesses often find themselves at a crossroads between different printing technologies. Two popular choices are UV DTF printers and sublimation printers. Each has its unique features, advantages, and applications. In this blog post, we will explore the differences between these two technologies, their benefits, and which one might be the best fit for your specific needs.

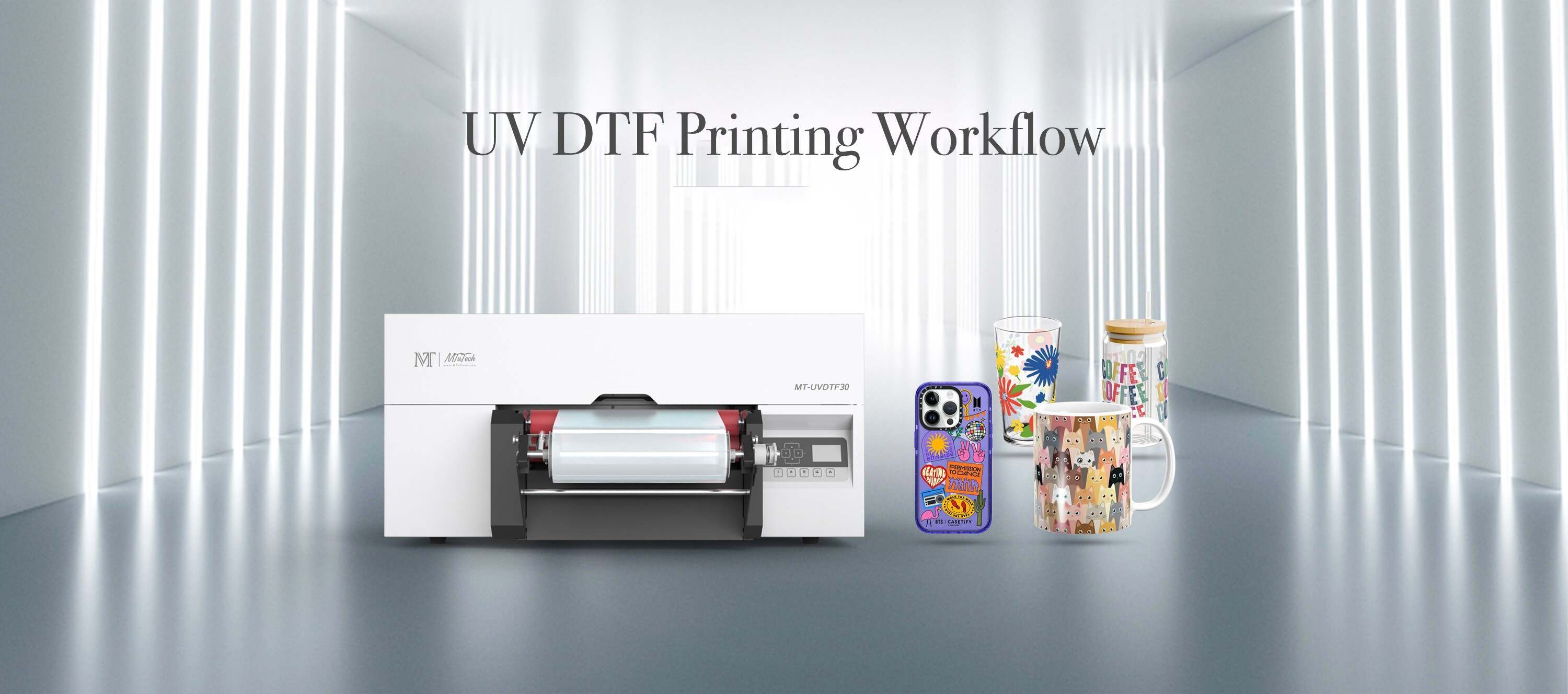

Understanding UV DTF Printing

UV DTF (Direct to Film) printing is a modern technique that utilizes UV light to cure ink as it is printed onto a special film. This technology allows for high-quality, vibrant prints on a variety of substrates, including those that are hard to print on with traditional methods.

Advantages of UV DTF Printing

Versatility: UV DTF printers can print on diverse materials, including plastics, wood, glass, and metals.

Durability: The cured inks are resistant to scratches, fading, and water, making them ideal for both indoor and outdoor applications.

Instant Drying: As the ink is cured instantly, the production process is faster compared to other printing methods.

High Quality: The resolution and color accuracy are exceptional, allowing for vibrant, detailed images.

Understanding Sublimation Printing

Sublimation printing is a dye transfer process that requires special inks and heat. The inks are turned into gas and infused into the material, creating a permanent bond. This process is especially popular for printing on polyester fabrics and coated materials.

Advantages of Sublimation Printing

Color Vibrancy: Sublimation allows for a wide range of colors and gradients, producing eye-catching designs that are rich in detail.

Soft Feel: Since sublimation dyes are transferred into the fabric, the finished product feels soft and maintains the material's flexibility.

Wash Durability: Designs printed via sublimation are less likely to fade or crack even after multiple washes.

Cost-Effective for Large Runs: Once the setup is established, sublimation can be very cost-effective, especially for bulk orders.

Key Differences Between UV DTF and Sublimation Printing

Materials Compatibility

One of the significant differences between UV DTF and sublimation printing is the range of materials they can print on:

UV DTF: Ideal for a variety of substrates including glass, metal, wood, plastic, and more

Sublimation: Best suited for synthetic fabrics (especially polyester) and specially coated materials

Print Quality and Durability

Both methods produce high-quality prints, but they differ in durability:

UV DTF: The prints are generally more durable and scratch-resistant, making them suitable for items that undergo regular handling.

Sublimation: Offers excellent wash durability, particularly for fabric applications, where it won’t crack or peel over time.

Production Speed and Cost

When evaluating production speed and cost, both printing methods have unique advantages:

UV DTF: Instant drying allows for rapid production, making it ideal for on-demand printing.

Sublimation: While setup can be intensive, the cost per print tends to decrease with larger quantities.

Applications for UV DTF Printing

UV DTF printers are ideal for various applications, such as:

Promotional products like pens, USB drives, and keychains

Custom signage and displays

Personalized gifts and collectibles

Industrial projects including labeling and branding

Applications for Sublimation Printing

Sublimation printing excels in several applications, including:

Custom apparel and sportswear, particularly for athletes and corporate branding

Home décor items like pillowcases, wall art, and curtains

Promotional merchandise such as mugs and phone cases, provided they are coated appropriately

Personalized gifts like photo quilts and custom blankets

Choosing the Right Printer for Your Needs

Selecting the ideal printing technology depends on your specific requirements. Here are some key questions to consider:

What materials will you be printing on? If you're working with a wide variety of substrates, a UV DTF printer may be the better choice. For fabric-focused needs, sublimation is preferred.

What durability do you need? For products subject to wear and tear, UV DTF provides greater durability, while sublimation excels in maintaining vibrant colors and soft texture in textiles.

Are you printing short runs or large quantities? If you need rapid production for short runs, UV DTF is favorable. If you're considering bulk orders of fabric items, sublimation might offer better economics.

Conclusion

Both UV DTF printers and sublimation printers have unique advantages that can make them the right choice depending on your specific needs. If versatility, durability, and instant drying are critical factors, then UV DTF printing may be the ideal solution. Conversely, if you're focused on vibrant graphics and soft-feel garments, sublimation may be the better option.

Ultimately, understanding the limitations and strengths of each printing method will help you make an informed decision that aligns with your business goals. Regardless of which technology you choose, investing in high-quality equipment is essential for achieving the best results. Explore our high-quality UV-DTF printers here.

FAQ

Can UV DTF printers print on fabric?

Yes, UV DTF printers can print on fabric, but the results may not be as soft or vibrant as those achieved with sublimation. They are more versatile for printing on other materials as well.

How long does sublimation printing last?

Sublimation prints can last for an extended period, especially when properly cared for, maintaining their color and feel even after multiple washes.

Which printer is better for small businesses?

It depends on the business's focus. A UV DTF printer is ideal for businesses that offer a wide range of products across different materials, while a sublimation printer is best for those focusing primarily on apparel and polyester items.

What is the initial investment for UV DTF and sublimation printers?

The initial investment varies widely based on the brand and features of the printer. UV DTF printers tend to have a higher upfront cost, while sublimation printers can be more budget-friendly, especially for entry-level models.