Introduction

Custom floor and wall graphics have emerged as innovative marketing tools and artistic expressions in various environments, from retail stores to corporate offices. The advent of UV (Ultraviolet) printing technology has revolutionized the way graphics are produced, offering unparalleled quality, durability, and versatility. In this blog post, we will explore how to print custom floor and wall graphics using UV technology, including the steps involved, the benefits of UV printing, and some tips for achieving the best results.

What is UV Printing?

UV printing is a modern printing technology that uses ultraviolet light to cure (or dry) the ink as it is printed. This process results in high-quality images that are vibrant, durable, and ready for handling immediately after printing. Unlike traditional printing methods that rely on solvents or water-based inks, UV inks are unique in that they are dried by ultraviolet light, enabling them to adhere to a variety of surfaces, including vinyl, wood, metal, and more.

Benefits of UV Printing for Custom Graphics

Utilizing UV technology for custom floor and wall graphics offers distinct advantages:

High Quality: UV printing creates sharp images with vibrant colors, enhancing the aesthetic appeal of any graphic.

Durability: The cured ink forms a tough surface that resists scratches, chemicals, and fading, making it ideal for high-traffic areas.

Versatility: UV printers can print on a wide variety of materials, expanding creative possibilities for custom graphics.

Eco-Friendly: UV inks emit fewer volatile organic compounds (VOCs) compared to solvent-based inks, making them a better choice for the environment.

Immediate Use: Since the ink dries almost instantly, graphics can be used immediately without the risk of smudging or fading.

Preparing for UV Printing

Before you begin printing, it’s essential to prepare adequately. Here’s what you need:

1. Choose Your Design Software

Select graphic design software that supports high-resolution images to ensure the best outcome. Adobe Illustrator, CorelDRAW, and Photoshop are popular choices among designers. Make sure to set your document to the final size of the graphic and use CMYK color mode for accurate color representation.

2. Select the Right Material

Choosing the correct substrate is crucial. Depending on your application—whether it’s for a floor or a wall—you’ll need materials that are specifically designed for durability and adhesion. Common materials include:

Vinyl

Polyester

Foam boards

Textured wall materials

3. Ensure High-Resolution Images

For high-quality prints, use high-resolution images (at least 300 DPI) to ensure that your graphics look crisp and professional. Blurry or pixelated images can detract from the overall quality of the graphic.

Printing Process

Once you have prepared your design and materials, you can move on to the printing process.

1. Setting Up Your UV Printer

Follow the manufacturer's guidelines to set up your UV printer. Ensure that all connections are secure, and the printing heads are clean. Check ink levels and load the selected material into the printer correctly. Many UV printers allow you to adjust settings for print quality, speed, and curing intensity; adapt these settings based on your design requirements.

2. Test Print

Conduct a test print on a smaller material piece to verify colors, alignment, and quality. This step helps to ensure that the final output matches your expectations without wasting larger materials.

3. Printing the Final Graphic

Once satisfied with the test print, proceed with printing the final graphic. Monitor the printing process to ensure everything functions correctly. Depending on your printer, you may be able to print multiple graphics at once, optimizing efficiency.

Finishing Touches

After printing, consider how you will finish your graphic to ensure durability and aesthetics:

1. Lamination

Laminating your graphics can add an extra layer of protection. For floor graphics, consider a slip-resistant laminate to enhance safety. For wall graphics, opt for a clear laminate to maintain the image’s vibrancy while providing durability.

2. Trimming and Cutting

Carefully trim excess material to achieve clean edges. Use a sharp utility knife or a cutting machine for precise cuts. If your design has unique shapes or intricate details, this step is particularly important.

3. Application

When applying your custom graphics, ensure the surface is clean and dry. This prevents any air bubbles or peeling in the future. For floor graphics, place them on a stable, flat surface and ensure proper adhesion. For wall graphics, use a squeegee tool to firmly press the graphic onto the wall, working from the center outward.

Tips for Successful Custom Graphics

To get the most out of your UV printing, keep these tips in mind:

Stay updated with the latest trends in graphic design to keep your creations fresh and engaging.

Regularly maintain your UV printer to ensure optimal performance and prevent ink clogging.

Experiment with different materials and finishes to differentiate your graphics and make them stand out.

Educate clients and users about the durability and maintenance of UV-printed graphics.

Conclusion

Printing custom floor and wall graphics using UV technology is an excellent way to enhance brand visibility and create an engaging environment. With the right preparation, quality materials, and advanced printing techniques, it’s possible to produce stunning graphics that are both eye-catching and durable. Whether you're a seasoned professional or just starting, integrating UV printing into your projects can open up new avenues of creativity and business opportunities.

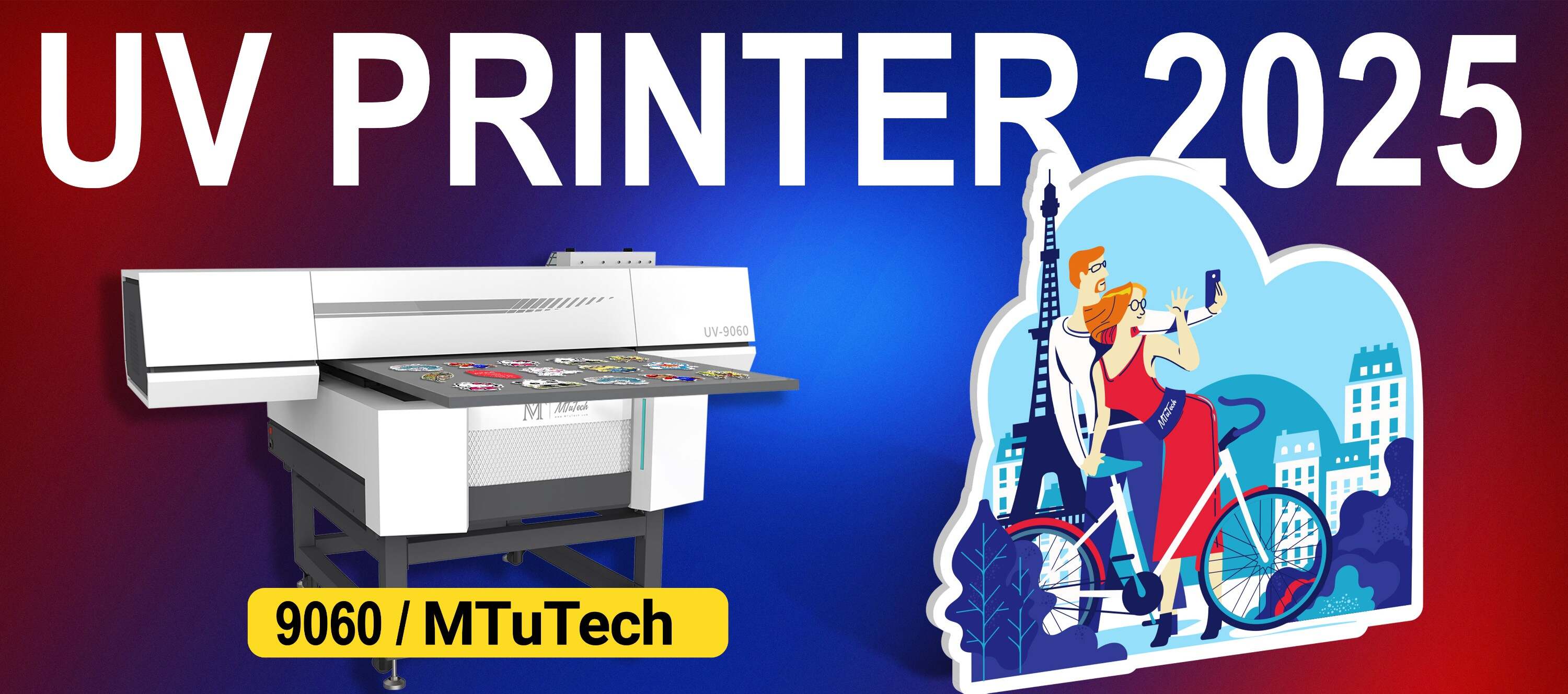

Explore our high-quality UV printers here to start your journey towards creating captivating floor and wall graphics. Happy printing!

FAQ

What is the difference between UV printing and traditional printing?

UV printing uses ultraviolet light to cure the inks as they are printed, which results in faster drying times and more vibrant colors compared to traditional printing methods that may require longer drying times and are more limited in the materials they can use.

Can UV-printed graphics be used outdoors?

Yes, UV-printed graphics are suitable for outdoor use due to their durability and resistance to fading from UV exposure and harsh weather conditions. However, it’s essential to select appropriate materials designed for outdoor applications.

Is UV printing more expensive than traditional printing?

While UV printing may have a higher initial cost due to the technology and materials involved, it often proves to be cost-effective in the long run due to its durability and the reduced need for frequent replacements.

What maintenance is required for UV-printed graphics?

UV-printed graphics require minimal maintenance. Regular cleaning with a damp cloth can help maintain their appearance. For floor graphics, it’s recommended to avoid abrasive cleaners that can damage the surface.